手动实验室压力机

手动纽扣电池封口机

货号 : PC2N

价格根据 规格和定制情况变动

- 压力范围

- 0-2T (0-25MPa)

- 活塞直径

- 32mm(d) 镀铬油缸

- 压力表

- 双刻度显示压力和压力

- 标准模具

- 标准CR20系列封装模具

运输:

联系我们 获取运输详情 享受 准时发货保证.

为什么选择我们

简易的订购流程、优质的产品和专业的支持,助力您的业务成功。

简介

手动纽扣电池封口机是一款专为小型纽扣电池(如CR2032、LR44等型号)设计的高精度包装设备,适用于实验室研发、小批量生产和教学演示。该设备利用机械杠杆原理和定制模具,可快速完成电池外壳的压合封口过程,确保电池内部电解液和电极材料的密封性,从而延长电池寿命并提高安全性。其操作简便、成本低廉的特点,使其成为中小型电池制造商、科研机构和电子维修行业的理想工具。

详情与部件

应用

- 手动纽扣电池封口机广泛应用于以下场景:

- 消费电子:智能手表、计算器、电子玩具等纽扣电池的封装。

- 医疗设备:助听器、便携式检测仪等微型电池的生产。

- 工业领域:物联网传感器、RFID标签等低功耗设备的电池组装。

- 科学研究与教育:高校实验室的小批量试制以及新能源材料研究。

特点

- 操作简便,灵活高效

- 符合人体工学设计的手动杠杆结构,无需电动驱动,单手即可操作加压。

- 支持快速更换模具,适配不同尺寸(直径5-25mm)的纽扣电池,切换效率高。

- 高精度封装工艺

- 配备高硬度合金模具,压力范围可调(0.5-5kN),确保壳体边缘均匀密封,无泄露风险。

- 误差精度控制在±0.05mm以内,符合国际电池封装标准。

- 耐用与安全并重

- 机身采用加固钢结构,耐磨性极佳,使用寿命超过10万次。

- 配备防滑底座和防护挡板,避免操作过程中部件移位或误触。

- 低成本维护

- 无复杂电子元件,日常仅需润滑保养,维护成本极低。

优势

- 高性价比,快速回本

- 相较于数万元的自动化封口机,手动型号仅需十分之一的价格,适合预算有限、投资回报周期短的企业。

- 提升产品良率

- 精确的压力控制可减少电池漏液、短路等问题,成品合格率高达99%,降低物料损耗成本。

- 适应多样化需求

- 支持定制模具开发,兼容锂锰电池、碱性电池等多种类型,满足客户特殊规格要求。

- 环保节能

- 零能耗设计符合绿色生产趋势,尤其适合注重可持续发展的企业。

技术规格

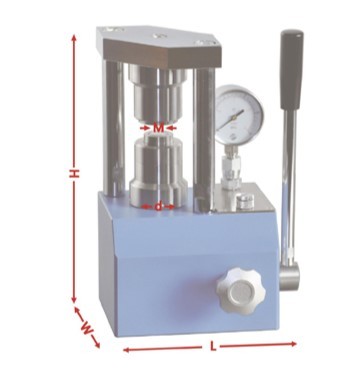

| 仪器型号 | PC-2N |

|---|---|

| 压力范围 | 0-2T (0-25MPa) |

| 活塞直径 | 32mm(d) 镀铬油缸 |

| 压力表 | 双刻度压力、压力显示 |

| 标准模具 | 标准CR20系列封装模具 |

| 封口模具 | 可选CR16、CR20、CR24、CR30等 |

| 封口压力 | 一般在0.8-1.2吨之间 |

| 拆壳模具 | 可选CR16、CR20、CR24、CR30等 |

| 拆壳压力 | 一般在0.4吨以内 |

| 外形尺寸 | 210*165*290mm(长*宽*高) |

| 设备重量 | 12Kg |

| 机器尺寸图 |  |

操作步骤

1. 将组装好的纽扣电池放入封口机的封口模具中。

2. 顺时针旋紧封口机的放油阀。

3. 来回摆动手柄杆,开始加压。

4. 将压力压至约6mpa-8mpa,约1000kg-1200kg。

5. 逆时针松开放油阀,卸压并将模具降回初始位置。

6. 从封口机中取出已封口好的纽扣电池。

7. 将测试好的纽扣电池放入拆壳模具中。

8. 将压力压至约2mpa-5mpa,即可分离纽扣电池。

9. 逆时针松开放油阀,卸压并将模具降回初始位置。

10. 从封口机中取出已分离的纽扣电池。

行业领军企业信赖之选

4.8 / 5

Excellent value! This sealer is a game-changer for our small lab. Simple, effective, and durable.

4.9 / 5

Impressed with the precision and build quality. A reliable tool for battery research. Highly recommended!

4.7 / 5

So easy to use! Perfect for small-scale production. Saves us time and money. Great investment.

4.8 / 5

Fantastic product! The sealing is consistent and leak-proof. Our battery yield has significantly improved.

4.9 / 5

A must-have for any battery lab. The adjustable pressure feature is brilliant. Top-notch quality!

4.7 / 5

Durable and efficient! This sealer is built to last. We've been using it daily with no issues.

4.8 / 5

Great for teaching! Easy for students to learn and operate. A valuable asset to our university lab.

4.9 / 5

Exceptional value for the price! Comparable to much more expensive models. Very satisfied with the purchase.

4.7 / 5

Quick mold changes make it versatile. Handles different battery sizes with ease. Very convenient!

4.8 / 5

Simple, yet effective design. Very little maintenance needed. A reliable workhorse.

4.9 / 5

Eco-friendly and energy-saving! Perfect for our green initiative. Performs flawlessly.

4.7 / 5

Excellent sealing quality, no leaks! Our production rate is up. Highly recommended!

4.8 / 5

Compact and easy to store. Doesn't take up much space. A great addition to our lab.

4.9 / 5

Improved our battery production yield significantly! Great value and performance!

4.7 / 5

Solid construction, feels very durable. Expecting years of reliable service!

4.8 / 5

Easy to operate, even for new staff. Training time reduced. Highly efficient.

4.9 / 5

Superb precision! Batteries are sealed perfectly every time. Delighted with this product!

获取报价

我们的专业团队将在一个工作日内回复您。请随时与我们联系!