为什么选择我们

简易的订购流程、优质的产品和专业的支持,助力您的业务成功。

应用

镍泡沫,作为“多孔金属”家族的一员,是一种轻质、多功能的材料,具有三维网络结构。其比重仅为0.2~0.3,与其他材料相比非常轻。由于其多孔网络,这种泡沫具有优异的吸声、导热和过滤能力。它具有96-98%的高孔隙率,在保持镍的优良特性的同时减轻了重量。这些特性使镍泡沫成为一种具有多样化应用的功能性新材料。

- 化学电源:增强镍氢、镍镉和燃料电池的性能,性能翻倍。适用于手机、电脑、踏板车等锂电池。

- 化学工程:用作净化器中的催化剂、过滤介质和分离器,降低能耗,提高效率。

- 电化学工程:提高制氢、电催化和冶金的能源效率。

- 热工工程:高效导热材料,使热管效率翻倍。

- 功能材料:吸收波能,提供降噪、减震、电磁屏蔽、阻燃和隔热功能。

- 应用包括:汽车尾气净化器、电池电极、催化剂载体、红外线燃烧器和加热材料。

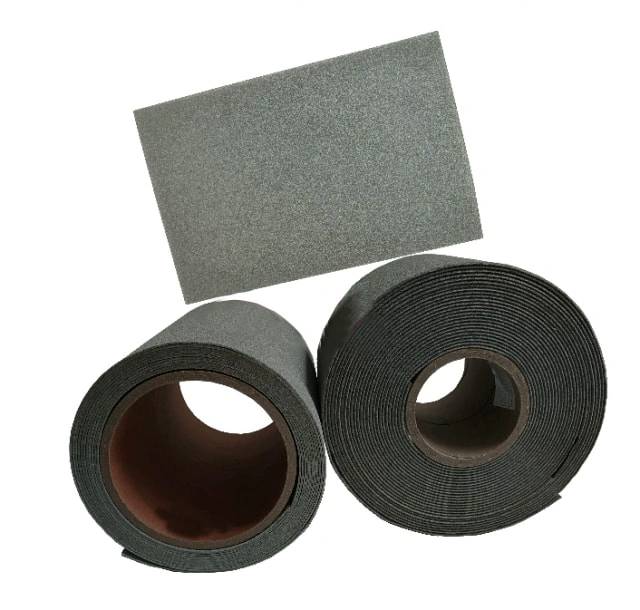

细节与部件

技术规格

| 孔径: | 0.1mm-10mm (5-120ppi) |

| 孔隙率: | 50%-98% |

| 孔隙率: | ≥98% |

| 堆积密度: | 0.1-0.8g/cm3 |

| 表面密度 (g/㎡) | 280~3000 (±30~200) |

| 厚度 (mm) | 0.5~10 (±0.05~1.0) |

| 长/宽尺寸(mm) | 70≤L/W≤500 (±0.5) |

| 尺寸 | 厚度0.3/0.5/1.0/1.5/1.7mm*宽度200mm*长度1m | 厚度0.3/0.5/1.0/1.5/2.0mm*宽度200mm*长度250mm | 厚度0.5/1.0/1.5/1.7/2.5/2.0mm*宽度200mm*长度300mm |

我们展示的产品有多种尺寸可供选择,也可根据要求定制尺寸。

优点

- 超轻质量:具有比表面积,比重为0.2~0.3,是水的1/4,木材的1/3,铝的1/10,铁的1/30。质量超轻。

- 吸声:多孔结构具有宽频吸声特性。

- 电磁波屏蔽:通过相对较薄的厚度,可屏蔽约90dB的电磁波。

- 加工性能:可切割、弯曲、易粘贴。

- 防火:保持形状稳定,高温下不易燃烧,耐高温。

- 回收利用:金属废料可回收利用。

- 透气性:均质三维网状结构具有过滤功能,气体和流体的流动稳定性极强。

- 隔音:通过附加处理,可获得高噪声截断,隔音效果好。

- 外观精美,内在实用:可通过多种饰面处理,适用于室内装饰。

- 耐高温:600度以上,耐各种酸碱腐蚀,渗透性好,孔结构均匀,加热和传热速度快。

行业领军企业信赖之选

4.8 / 5

Nickel Foam's sound absorption is exceptional, making it perfect for studios and noisy environments.

4.9 / 5

The Nickel Foam from KINTEK SOLUTION is a game-changer for our battery production. It enhances performance and extends battery life significantly.

4.7 / 5

Nickel Foam's heat conduction is remarkable. It has doubled the efficiency of our heat pipes, leading to improved performance and energy savings.

4.6 / 5

The processing flexibility of Nickel Foam is fantastic. We can easily cut, bend, and paste it, making it incredibly versatile for various applications.

4.8 / 5

The recyclability of Nickel Foam is a huge plus. It aligns with our sustainability goals and reduces our environmental impact.

4.9 / 5

The breathability of Nickel Foam is impressive. Its three-dimensional mesh structure allows for efficient filtering and gas/fluid flow.

4.7 / 5

The sound insulation provided by Nickel Foam is exceptional. It effectively reduces noise pollution, creating a quieter and more comfortable environment.

4.6 / 5

The high temperature resistance of Nickel Foam is impressive. It withstands extreme heat and various acid and alkali corrosion, making it ideal for demanding applications.

4.8 / 5

Nickel Foam's sophisticated yet practical design makes it a perfect choice for interior decoration. It combines aesthetics with functionality flawlessly.

4.9 / 5

The fast heating and heat transfer of Nickel Foam are remarkable. It significantly improves the efficiency of heating systems, reducing energy consumption.

获取报价

我们的专业团队将在一个工作日内回复您。请随时与我们联系!

相关文章

探索火花等离子烧结 (SPS) 炉的先进功能

深入了解火花等离子烧结炉(SPS)、其创新技术以及在材料科学中的应用。了解 SPS 炉如何通过高速、高效和精确彻底改变烧结工艺。

火花等离子烧结炉综合指南》:应用、特点和优势

探索火花等离子烧结炉 (SPS) 在材料科学领域的先进功能和应用。了解 SPS 技术如何为各种材料提供快速、高效和多功能烧结。

关于活性碳热再生技术的全部内容

活性炭再生简介、方法和选择

电化学电极的未来

电极材料的最新趋势和发展及其对未来电化学的影响。

了解等静压工艺:从开始到应用

等静压工艺开创于 20 世纪 50 年代中期,从最初的研究好奇心逐渐发展成为一种可行的生产工具。该工艺适用于各种材料,包括陶瓷、金属、复合材料、塑料和碳。它为陶瓷和耐火材料应用提供了独特的优势,使产品形状的形成符合精确的公差要求,并减少了昂贵的机加工需求。

掌握手持式涂层测厚仪:工业和汽车应用综合指南

探索手持式涂层测厚仪的复杂性及其在电镀、汽车涂料和粉末涂料中的应用。了解如何选择和有效使用这些仪器,以实现质量控制和成本效益。