为什么选择我们

简易的订购流程、优质的产品和专业的支持,助力您的业务成功。

简介

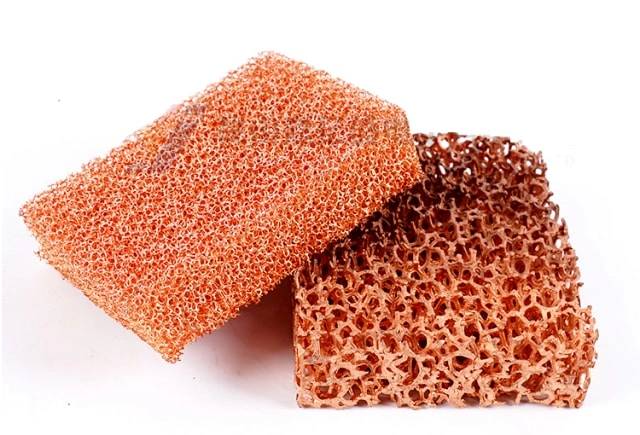

铜泡沫是一种均质的三维网络结构,具有过滤功能,气体和流体的流动稳定性极强。铜骨架中空,在冶金状态下相互连通。孔隙率高达96-98%,堆积密度仅为铜的五十分之一。比表面积极大,并保持了铜优良的物理化学性质。因此,这种新结构的优异特性使其成为应用领域更广泛的功能性新材料。

主要特点

- 优异的导热和导电性——是电子、电机和电池的理想选择。

- 超轻高孔隙率——96-98%的多孔性,密度为实心铜的1/50。

- 过滤和催化——高表面积,适用于医疗过滤器、水净化和催化剂载体。

- 噪音和电磁干扰控制——吸收声音并提供电磁屏蔽。

- 易于加工——可切割、弯曲和粘合。

细节和零件

技术规格

| 孔径: | 0.1mm-10mm (5-130ppi) |

| 孔隙率: | 50%-98% |

| 贯穿孔率: | ≥98% |

| 每英寸孔数: | 110 (110PPI) |

| 堆积密度: | 0.1-0.8g/cm3 |

| 表面密度 G/M²: | 280-3000(±30-200) |

| 厚度(MM): | 0.1~40(0.05~1.0) |

| 孔数 PPI: | 13~1300(±5~10) |

| 长度/宽度/厚度尺寸(MM): | 70≤长度和宽度<500(±0.5)厚度 0.1-25mm |

可用的铜泡沫规格

我们展示的产品有不同尺寸可供选择,也可根据要求定制尺寸。

| 尺寸(长*宽*厚) | |||

| 100mm*100mm*5.0mm | 100mm*100mm*6.0mm | 100mm*100mm*7.0mm | 100mm*100mm*8.0mm |

| 100mm*100mm*9.0mm | 100mm*100mm*10.0mm | 200mm*200mm*0.5mm | 200mm*200mm*1.0mm |

| 200mm*200mm*1.2mm | 200mm*200mm*1.5mm | 200mm*200mm*1.8mm | 200mm*200mm*2.0mm |

| 200mm*200mm*2.2mm | 200mm*200mm*2.5mm | 200mm*200mm*2.8mm | 200mm*200mm*3.0mm |

| 200mm*200mm*4.0mm | 200mm*200mm*5.0mm | 200mm*200mm*6.0mm | 200mm*200mm*7.0mm |

| 200mm*200mm*8.0mm | 200mm*200mm*9.0mm | 200mm*200mm*10.0mm | 200mm*300mm*0.5mm |

| 200mm*300mm*1.2mm | 200mm*300mm*1.5mm | 200mm*300mm*1.8mm | 200mm*300mm*2.0mm |

| 200mm*300mm*2.2mm | 200mm*300mm*2.5mm | 200mm*300mm*2.8mm | 200mm*300mm*3.0mm |

| 200mm*300mm*4.0mm | 200mm*300mm*5.0mm | 200mm*300mm*6.0mm | 200mm*300mm*7.0mm |

| 200mm*300mm*8.0mm | 200mm*300mm*9.0mm | 200mm*300mm*10.0mm |

应用

- 电池和超级电容器电极

- 催化剂载体和空气净化

- 散热器和热管理

- 吸音和电磁干扰屏蔽

- 过滤和流体压力缓冲

为您而设计

KinTek为全球客户提供深度定制服务和设备,我们专业的团队和经验丰富的工程师有能力承担定制硬件和软件设备的需求,并帮助我们的客户 打造专属个性化设备和解决方案!

请将您的想法告诉我们,我们的工程师已经为您准备好了!

行业领军企业信赖之选

FAQ

4.9 / 5

Incredibly lightweight yet robust! Transformed our thermal management system. The porosity is perfect for airflow.

4.8 / 5

Arrived faster than expected! The quality is exceptional, and it was so easy to cut to the exact size we needed.

4.7 / 5

A fantastic value for such a high-tech material. Our battery prototypes are performing better than ever.

4.9 / 5

The EMI shielding properties are outstanding. A truly advanced material that's surprisingly simple to work with.

4.8 / 5

So durable! It's holding up perfectly in our harsh filtration environment. Exceeded all our expectations.

4.7 / 5

The high surface area is a game-changer for our catalysis research. The material is consistently high-quality.

4.9 / 5

Perfect for sound absorption panels. The delivery was lightning-fast, and the product is precisely as described.

4.8 / 5

An incredible material that's both lightweight and highly conductive. Excellent value for the performance.

4.7 / 5

I'm amazed by how well it handles heat dissipation. A must-have for any serious electronics project.

4.9 / 5

The technological advancement in this foam is palpable. It integrated seamlessly into our prototype design.

4.8 / 5

Cutting and shaping it was a breeze. The structural integrity is impressive for something so light.

4.7 / 5

Fast shipping and a product that delivers on every promise. Our heat sink efficiency has skyrocketed.

4.9 / 5

The purity and consistency of the copper foam are remarkable. A premium product that's worth every penny.

4.8 / 5

Its versatility is astounding. We're using it for filtration and EMI shielding with fantastic results.

4.7 / 5

A revolutionary material. The high porosity makes it ideal for advanced fluid dynamics applications.

4.9 / 5

The quality is unmatched. This foam has significantly improved the longevity of our components.

4.8 / 5

Incredibly easy to process. We bonded it to other materials without any issues. Highly recommended!

4.7 / 5

Perfect for pressure buffering. The three-dimensional structure is beautifully uniform throughout.

4.9 / 5

A technological marvel. The combination of low density and high conductivity is simply brilliant.

4.8 / 5

Durable, efficient, and arrived ahead of schedule. This foam has become an essential component for us.

4.7 / 5

The value for money is exceptional. We've tested several foams, and this one outperforms them all.

4.9 / 5

The electrical conductivity is phenomenal. It's perfect for our high-performance battery electrodes.

4.8 / 5

An absolute pleasure to work with. The material is both innovative and incredibly reliable.

4.7 / 5

Fast delivery and a product that is clearly built to last. It has excellent corrosion resistance.

4.9 / 5

The pore structure is perfectly interconnected. It's the ideal catalyst support for our chemical processes.

4.8 / 5

A top-tier material that is surprisingly affordable. It has revolutionized our approach to thermal design.

4.7 / 5

The sound absorption qualities are impressive. It's a versatile material that solves multiple problems.

4.9 / 5

The quality control is evident. Every sheet we've received has been flawless and ready for immediate use.

4.8 / 5

A fantastic product backed by great service. The custom size option was a huge benefit for our project.

获取报价

我们的专业团队将在一个工作日内回复您。请随时与我们联系!

相关产品

定制PTFE特氟龙漏斗制造商,提供PTFE布氏漏斗和三角漏斗

PTFE漏斗是一种实验室设备,主要用于过滤过程,特别是在混合物中分离固体和液体相。这种装置可以实现高效快速的过滤,在各种化学和生物应用中不可或缺。

定制PTFE特氟龙网筛制造商,用于PTFE网筛F4筛分器

PTFE网筛是一种专门的试验筛,用于分析各种行业中的颗粒。它采用由PTFE长丝编织而成的非金属网。这种合成网非常适合担心金属污染的应用。PTFE筛对于保持敏感环境中样品的完整性至关重要,确保颗粒尺寸分布分析的准确性和可靠性。

相关文章

关于活性碳热再生技术的全部内容

活性炭再生简介、方法和选择

电极夹具指南:类型、设计和应用

了解电极夹具的全面指南,涵盖各种类型、设计注意事项以及电极夹具在电镀、焊接和电化学电池等行业中不可或缺的作用。

了解冷等静压工艺:工艺、优势和类型

冷等静压(CIP),又称冷等静压实,是一种材料加工技术,它是指将材料从各个侧面施加均匀的压力。这是通过将材料浸入高压流体介质并施加液压来实现的。CIP 对粉末状材料的成型和加固特别有效,可以制造出复杂的形状并达到较高的生坯密度。

了解热等静压工艺:用途、应用和规格

热等静压(HIP)是一种功能强大的制造工艺,在提高陶瓷材料密度和减少金属孔隙率方面发挥着至关重要的作用。它广泛应用于各行各业,包括航空航天、粉末冶金和零部件制造。

冷等静压技术的优点

冷等静压(CIP)是一种用于将粉末压制成特定形状或尺寸的工艺。这种方法包括在液体介质中对粉末施加高压,压力通常在 100 到 200 兆帕之间。

等静压工艺是挤压工艺的低失真替代工艺

等静压是一种利用高压将粉末状材料压缩成特定形状或形态的制造工艺。

热等静压技术为何如此有效

热等静压(HIP)是一种利用高温高压改善材料机械性能的制造工艺。该工艺包括将零件置于密封腔内,并对其施加高温和高压。

用于航空航天应用的等静压机

等静压是一种利用压力制造具有一致密度和强度的统一部件的制造工艺。该工艺是将材料放入一个柔性容器中,然后从四面加压以形成统一的形状。

电压的静默几何:尊重电解的极限

电解依赖于严格的电气边界。了解为什么超过额定电流和电压不仅效率低下,而且具有破坏性。

寂静的架构:为何材料选择决定电化学真理

探索高硼硅玻璃、PTFE 和 POM 如何创造完美的化学惰性环境,以实现准确的电化学测试。