为什么选择我们

简易的订购流程、优质的产品和专业的支持,助力您的业务成功。

应用

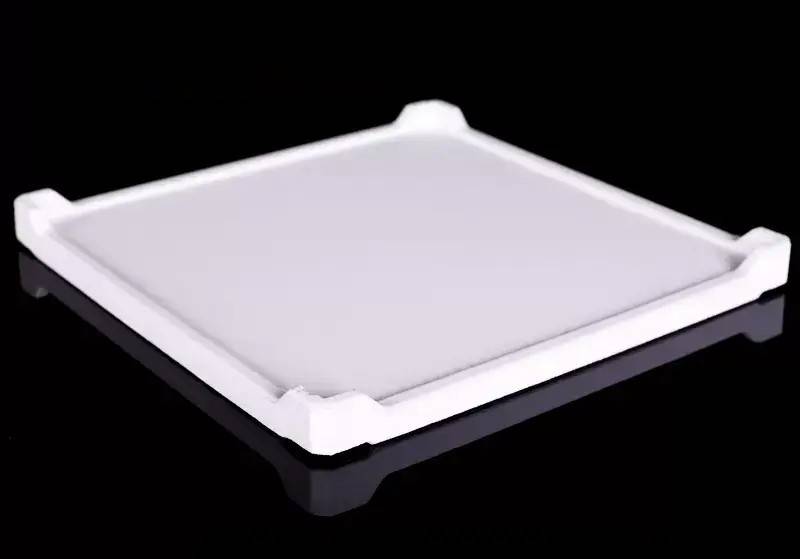

精细刚玉氧化铝匣钵,也称为陶瓷承烧板,是在陶瓷窑中输送和承载烧成陶瓷体的必备工具。这些板材以高纯度刚玉和莫来石为主要原料。通过结合两种材料的优异性能,创造出一种耐高温复合承烧板,为陶瓷窑操作提供了诸多优势和特性。在本文中,我们将更详细地探讨精细刚玉板的优势和功能。

- 烧成陶瓷的载体:精细刚玉板的主要功能是作为烧成陶瓷的载体、保温和运输。这些板材有助于陶瓷产品的均匀加热,从而提高传热速率和能源效率。

- 超高温应用:在超高温电窑和电炉中,精细刚玉板常用作推板、承载板和匣钵板。它们能够承受极端温度的能力使其适用于此类应用。

- 工业陶瓷的高温烧结:该板材适用于工业陶瓷的无污染高温烧结工艺。它们用于磁性材料、粉末冶金、陶瓷基板和氧化锆陶瓷的烧结,确保可靠且受控的烧结条件。

- 电子元件的烧结:精细刚玉板也用于多层陶瓷电容器 (MLCC)、低温共烧陶瓷 (LTCC)、正温度系数 (PTC) 片式电阻器和电容器等电子元件的烧结。这些板材为这些元件的精确烧结提供了合适的环境,确保了其质量和功能。

- 这些板材充当烧成陶瓷的载体,提高了传热、能源效率和烧制速度。它们还用于超高温应用、技术陶瓷烧结和电子元件烧结。使用细绳。

细节与零件

| 精细条纹匣钵 | 100x100x13mm95 | 105x105x12mm99 |

| 精细条纹匣钵 | 103x103x22mm | 118x100x19mm |

| 精细条纹匣钵 | 120x120x40mm | 195x100x32mm |

| 精细刚玉烧结台 | 100x100x15mm95 氧化铝 - 缺口 | 105x105x12mm99 氧化铝 - 缺口 |

| 精细刚玉烧结台 | 250*250mm |

我们展示的坩埚有不同尺寸可供选择,也可根据要求定制尺寸。

优点

- 高工作温度:这种耐高温性确保了它们在烧结过程中的可靠性和稳定性。

- 优异的热震稳定性:它们能够承受快速的温度变化而不会破裂或断裂。

- 低膨胀系数:确保尺寸稳定性,防止烧成陶瓷产品翘曲或变形。

- 高抗弯强度:这种强度确保了承烧板的耐用性和寿命。

- 高温负载下的理想软化性能:精细刚玉板在高温负载下仍能保持结构完整性和形状。此功能可在整个烧制过程中实现一致且可靠的性能。

- 使用寿命长:精细刚玉板具有综合使用寿命长。这种长寿命减少了频繁更换的需要,从而为窑炉操作员节省了成本。

总之,精细刚玉板具有工作温度高、热震稳定性好、膨胀系数低、抗弯强度高、高温负载软化性能理想、使用寿命长等优点。

行业领军企业信赖之选

FAQ

什么是先进陶瓷?

什么是工程陶瓷?

精细陶瓷的主要用途有哪些?

先进陶瓷的主要类型有哪些?

工程陶瓷的主要类型有哪些?

精密陶瓷的主要类型有哪些?

先进陶瓷的应用领域有哪些?

工程陶瓷有哪些应用?

精密陶瓷的原理是什么?

如何制造先进陶瓷?

工程陶瓷与传统陶瓷有何不同?

使用精密陶瓷有哪些优势?

使用先进陶瓷有哪些优势?

使用氧化铝陶瓷有哪些优势?

氧化铝陶瓷和氧化锆陶瓷有什么区别?

为什么在某些应用中首选氧化锆陶瓷?

碳化硅陶瓷为何用于高温应用?

碳化硅陶瓷为何适合高温应用?

氮化硼陶瓷有何独特之处?

氮化硼陶瓷如何用于电子产品?

先进陶瓷如何提高能源效率?

工程陶瓷的制造工艺是什么?

工程陶瓷能否针对特定应用进行定制?

4.8 / 5

The Alumina Ceramic Saggar has exceeded my expectations. Its exceptional quality and durability make it an indispensable tool for our ceramic kiln operations.

4.9 / 5

I highly recommend the Alumina Ceramic Saggar. Its high operating temperature and excellent thermal shock stability have significantly improved our sintering process.

4.7 / 5

The Fine Corundum Burning Table has been a game-changer for our electronic component sintering. Its precise temperature control ensures consistent and reliable results.

4.8 / 5

The long service life of the Fine Corundum Plate has saved us both time and money. Its durability is truly impressive.

4.9 / 5

The Alumina Ceramic Saggar has revolutionized our ceramic kiln operations. Its ability to withstand rapid temperature changes has minimized defects and improved product quality.

4.7 / 5

The Fine Corundum Plate's high bending strength ensures the longevity of our kiln operations. It's a reliable and durable investment.

4.8 / 5

The Alumina Ceramic Saggar's low coefficient of expansion has significantly reduced warping and deformation of our fired ceramic products. It's a valuable addition to our kiln.

4.9 / 5

The Fine Corundum Burning Table's ideal softening properties under high temperature loads have improved the consistency and reliability of our sintering process.

4.7 / 5

The Alumina Ceramic Saggar's high-purity and high-temperature characteristics have taken our ceramic kiln operations to the next level.

4.8 / 5

The Fine Corundum Plate's excellent thermal shock stability has eliminated cracking and fracturing during temperature changes. It's a game-changer for our sintering process.

4.9 / 5

The long service life of the Fine Corundum Plate has saved us both time and money. It's a cost-effective and reliable solution for our kiln operations.

4.7 / 5

The Alumina Ceramic Saggar's high operating temperature ensures the reliability and stability of our sintering process. It's a crucial tool for our ceramic kiln operations.

4.8 / 5

The Fine Corundum Burning Table's precise temperature control has improved the quality and consistency of our electronic components. It's a valuable addition to our manufacturing process.

4.9 / 5

The Fine Corundum Plate's bending strength ensures the longevity of our kiln operations. It's a durable and reliable investment.

4.7 / 5

The Alumina Ceramic Saggar's low coefficient of expansion has significantly reduced warping and deformation of our fired ceramic products. It's a valuable addition to our kiln.

4.8 / 5

The Fine Corundum Burning Table's ideal softening properties under high temperature loads have improved the consistency and reliability of our sintering process.

4.9 / 5

The Alumina Ceramic Saggar's high-purity and high-temperature characteristics have taken our ceramic kiln operations to the next level.

4.7 / 5

The Fine Corundum Plate's excellent thermal shock stability has eliminated cracking and fracturing during temperature changes. It's a game-changer for our sintering process.

4.8 / 5

The long service life of the Fine Corundum Plate has saved us both time and money. It's a cost-effective and reliable solution for our kiln operations.

获取报价

我们的专业团队将在一个工作日内回复您。请随时与我们联系!

相关产品

弧形氧化铝陶瓷坩埚 高温耐受工程先进陶瓷

在科学探索和工业生产的征程中,每一个细节都至关重要。我们的弧形氧化铝陶瓷坩埚,凭借其出色的耐高温性和稳定的化学性质,已成为实验室和工业领域的得力助手。它们采用高纯度氧化铝材料制成,并经过精密工艺制造,确保在极端环境下也能有卓越的表现。

先进工程陶瓷低温氧化铝造粒粉

低温氧化铝造粒粉是一种通过特殊低温工艺生产的氧化铝颗粒,旨在满足对温度敏感的应用需求。该材料具有优异的低温性能和良好的加工特性,适用于多种需要低温加工和处理的行业。

相关文章

安装二硅化钼(MoSi2)加热元件时的注意事项

安装 MoSi2 加热元件时的注意事项

用于热分析测试容器的氧化铝陶瓷坩埚

关于选择和使用氧化铝陶瓷坩埚进行热分析测试的深入指南,重点介绍影响测试结果的因素。

精密铸造中的氧化铝坩埚

探讨氧化铝坩埚在精密铸造中的应用,重点介绍其在高温合金熔炼中的特性和优势。

高温炉用莫来石纤维内衬的优势

探讨高温工业炉中莫来石纤维衬里的优点,重点是热稳定性、能源效率和长期成本节约。

半导体应用中的精密陶瓷

探索半导体设备中精密陶瓷的使用、特性和制造工艺。

深入了解氧化锆烧结炉

探讨氧化锆烧结工艺、熔炉组件以及实现高质量牙科修复的最佳条件。

适合在高温马弗炉中煅烧的物质

适合在高温马弗炉中煅烧的材料和实验概述。

真空感应熔炼炉用氧化铝坩埚的制备和性能

本文讨论了用于真空感应熔炼炉的氧化铝坩埚的制备工艺和性能优势,强调了热稳定性和长使用寿命。

用于能源转换应用的精密陶瓷材料

概述能源转换技术中使用的各种陶瓷材料,包括加热器、压电陶瓷和固体氧化物燃料电池。

粉末冶金氧化铝坩埚综合指南

深入了解氧化铝坩埚在粉末冶金工艺中的特性、应用和使用。

陶瓷的机械性能和结构增强

深入分析陶瓷的机械性能,包括优点、缺点和改进方法。

等静压陶瓷球的缺陷和解决方案

本文讨论了等静压陶瓷球中的各种缺陷,并针对每种缺陷提供了解决策略。