真空加热实验室压力机

触摸屏自动真空热压机

货号 : PPZC

价格根据 规格和定制情况变动

- 加热温度

- 300°C /500℃/800°C

- 压力范围

- 0.01-5.0 吨

运输:

联系我们 获取运输详情 享受 准时发货保证.

为什么选择我们

简易的订购流程、优质的产品和专业的支持,助力您的业务成功。

应用

触摸屏自动真空热压机通过实现精确、无污染的粘合和成型,彻底改变了实验室材料加工方式。该先进系统对于需要精确控制条件下完美层压的研发设施、质量控制实验室和专业生产单位至关重要。其真空辅助操作消除了光伏电池、电子产品和复合材料封装过程中的气泡——这对于防止太阳能电池板或微电子元件的分层至关重要。该系统可编程的多级功能支持复杂的工艺流程,例如航空航天合金的扩散粘合,其中交替的压力和温度曲线可在没有热变形的情况下实现分子级融合。

对于材料科学应用,它有助于石墨烯在基板之间的转移和聚合物纳米复合材料的固结,即使是微米级的空隙也会损害导电性。快速冷却功能可对热塑性原型进行淬火,而不会产生结晶缺陷,这对于需要结构完整性的 3D 打印医疗植入物至关重要。开发柔性电路的实验室利用其均匀的压力分布(0.01-5.0 吨范围)将导电迹线嵌入对温度敏感的聚酰亚胺薄膜中。真空室还支持烧结前的陶瓷生坯致密化等厌氧工艺,其中捕获的氧气会导致开裂。

主要工业应用包括:

- 汽车:粘合碳纤维增强聚合物 (CFRP) 以制造轻质结构部件

- 光子学:制造需要无气泡界面的抗反射涂层光学镜片

- 生物医学:层压具有生物相容性密封件的微流控设备

- 能源:在无湿气条件下进行固态电池电极堆叠

- 航空航天:钛蜂窝芯三明治面板生产

研究人员必须咨询 KINTEK 专家以进行样品兼容性验证,特别是在处理需要低于 1°C/min 的升温速率的新型纳米材料或热敏生物材料时。

特点

技术规格

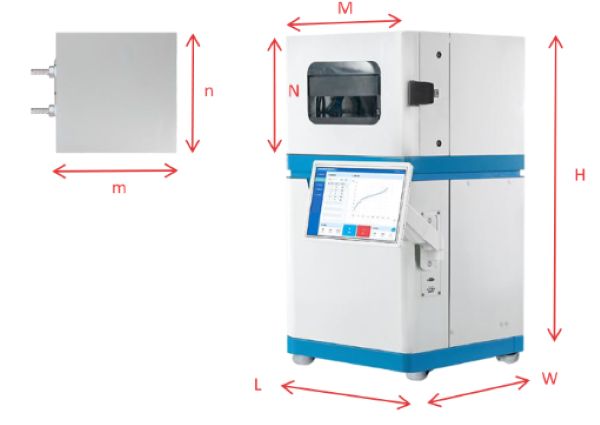

| 参数 | 120×120 | 200×200 | 300×300 | 400×400 |

|---|---|---|---|---|

| 加热温度/功率 | 室温 -300°C / 1.6KW 室温 -500°C / 2KW 室温 -800°C / 4.5KW |

室温 -300°C / 2.2KW 室温 -500°C / 3.4KW 室温 -800°C / 6KW |

室温 -300°C / 3KW 室温 -500°C / 4.5KW |

室温 -300°C / 4KW 室温 -500°C / 6KW |

| 压力范围 | 0.01-5.0 吨 | 0.01-25.0 吨 | 0.01-30.0 吨 | 0.01-50.0 吨 |

| 压力精度 | 0.01 吨 | |||

| 真空 | 0.1 MPa | |||

| 显示屏 | 7 英寸 (IPS 高清) 触摸屏 | |||

| 金属按钮 | 镀银触点,使用寿命 >100,000 次循环 | |||

| 图表 | 显示每次操作的图表,支持通过 USB 下载 Excel 文件 | |||

| 程序控制 | 最多 18 个可编程控制级别:压力/温度/真空/进气/水冷 每个均可单独控制。 | |||

| 真空控制 | 支持手动激活真空泵和进气阀,以及在多级程序中自动控制真空室的真空度。 | |||

| 水冷 | 支持手动水冷,以及多级程序中的自动快速冷却。 | |||

| 速度调节 | 可调节的压力和温度斜率。 | |||

| 远程控制 | 需要可选的计算机进行数据分析、比较、修改和导出。 | |||

| 平板尺寸 | 120 x 120 毫米 (m x n) | 200 x 200 毫米 (m x n) | 300 x 300 毫米 (m x n) | 400 x 400 毫米 (m x n) |

| 工作空间 | 130 x 55 毫米 | 210 x 65 毫米 | 320 x 70 毫米 | 420 x 90 毫米 |

| 门尺寸 | 300 x 200 毫米 (M x N) | 380 x 200 毫米 (M x N)< | 380 x 200 毫米 (M x N)< | 480 x 200 毫米 (M x N)< |

| 电源 | 220V/110V 可定制 | |||

| 真空泵尺寸/重量 | 490 x 230 x 340 毫米 / 14 公斤 | |||

| 产品尺寸/重量 | 480 x 560 x 750 毫米 (长 x 宽 x 高) / 280 公斤 | 580 x 660 x 1200 毫米 (长 x 宽 x 高) / 480 公斤 | 580 x 680 x 1200 毫米 (长 x 宽 x 高) / 580 公斤 | 680 x 760 x 1200 毫米 (长 x 宽 x 高) / 1130 公斤 |

| 包装尺寸/重量 | 900 x 800 x 1400 毫米 (长 x 宽 x 高) / 350 公斤 | 900 x 800 x 1400 毫米 (长 x 宽 x 高) / 550 公斤 | 900 x 800 x 1400 毫米 (长 x 宽 x 高) / 650 公斤 | 900 x 800 x 1400 毫米 (长 x 宽 x 高) / 1200 公斤 |

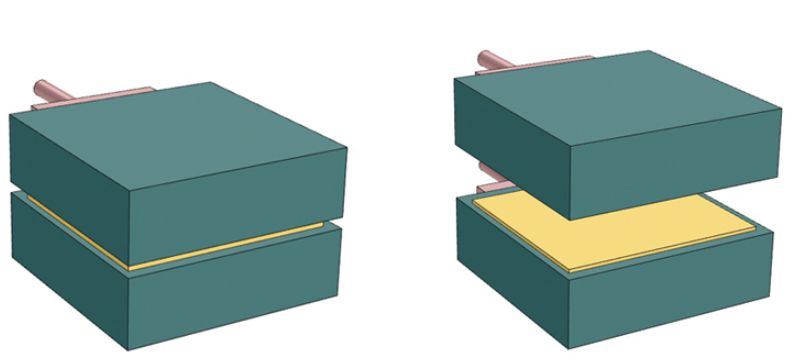

模具

行业领军企业信赖之选

4.9 / 5

This heat press is a game-changer! The precision and speed are unmatched. Worth every penny!

4.8 / 5

Incredible quality and durability. Perfect for our lab's demanding needs. Highly recommend!

4.7 / 5

Fast delivery and easy setup. The touchscreen interface is so intuitive. Love it!

4.9 / 5

The vacuum feature is flawless. No more air bubbles in our laminations. Brilliant!

4.8 / 5

Superior technology at an affordable price. Our lab's efficiency has skyrocketed!

4.7 / 5

Durable and reliable. Perfect for high-volume production. A must-have!

4.9 / 5

The programmable settings are a lifesaver. Customizable for any project. Amazing!

4.8 / 5

Top-notch build quality. Handles our toughest materials with ease. Impressive!

4.7 / 5

Arrived sooner than expected. The performance exceeds all expectations. Stellar!

4.9 / 5

The rapid cooling function is a game-changer. Perfect for our prototypes. Love it!

4.8 / 5

Value for money is unbeatable. Our lab's productivity has never been higher!

4.7 / 5

The uniform pressure distribution is perfect for delicate materials. Highly recommend!

4.9 / 5

The vacuum chamber is a dream. No more contamination issues. Perfect!

4.8 / 5

The touchscreen makes everything so easy. Setup was a breeze. Fantastic!

4.7 / 5

Durable and efficient. Handles our high-demand projects flawlessly. Excellent!

4.9 / 5

The multi-stage capabilities are revolutionary. Perfect for complex workflows. Amazing!

获取报价

我们的专业团队将在一个工作日内回复您。请随时与我们联系!

相关产品

带加热板的加热液压压机,用于真空箱实验室热压

使用我们的真空箱实验室压片机,提高实验室的精度。在真空环境中轻松精确地压制药片和粉末,减少氧化,提高一致性。体积小巧,易于使用,配有数字压力表。

30T 40T 分体式自动加热液压压机带加热板用于实验室热压

了解我们分体式自动加热实验室压机 30T/40T,适用于材料研究、制药、陶瓷和电子行业的精确样品制备。占地面积小,加热高达 300°C,非常适合在真空环境下进行加工。

工程高级陶瓷镊子带尖头弯头氧化锆陶瓷尖端

氧化锆陶瓷镊子是一种采用先进陶瓷材料制成的高精度工具,特别适用于需要高精度和耐腐蚀性的操作环境。这类镊子不仅具有优异的物理性能,而且因其生物相容性而在医疗和实验室领域广受欢迎。

相关文章

液压困境:先进材料制造中的单轴与双轴压力

在真空热压机中选择单轴压力还是双轴压力,是在简单性与最终材料均匀性之间进行的关键权衡。

静默的力量:通过可控压力锻造卓越的金属部件

了解热模锻如何利用缓慢、连续的压力来精炼金属的晶粒结构,从而制造出具有无与伦比的强度和可靠性的零件。

压力下的精准:液压热压机的物理学与心理学

了解液压热压机中的热量与压力如何协同作用,在帕斯卡定律的精妙物理学指导下,转化材料。

您的覆膜机为何会毁掉文件——以及如何一劳永逸地解决这个问题

厌倦了您的覆膜机将热敏打印件或照片变成黑色污迹?找出其发生的简单原因,以及如何选择正确的方法。

真空炉的悖论:完美真空的危害

了解深真空如何通过升华破坏合金,以及分压系统如何恢复热平衡和化学完整性。

超越蛮力:为什么最强的材料也会失效以及您的实验室如何预测它

了解为什么只关注蛮力是一种错误。了解材料微观结构——而不仅仅是规格——如何防止失效以及如何修复它。

虚无的架构:当最佳成分是真空

高温遇上零气压。了解真空炉如何消除污染,以及去除空气为何是提高材料强度的关键。

虚无的架构:用真空炉掌握精密

了解为什么没有空气是终极工程工具。我们探讨真空炉如何消除变量、确保纯度并重新定义材料性能。

您的压缩测试为何失败(并非样品的问题)

找出导致材料压缩测试失败并损坏设备的隐藏原因。了解为何压板(而非样品)常常是罪魁祸首。

真空炉的架构:控制压力

真空炉的精度不在于加热,而在于空气的缺失。探索压力范围的控制如何定义材料的完整性。

塑造潜能 vs. 锻造完美:等静压技术指南

深入探讨冷等静压(CIP)用于成型零件与热等静压(HIP)用于完善零件之间的关键区别。

力的几何学:为什么在材料科学中,压力不仅仅是压力

单轴热压为简单形状提供了速度,而等静压则为复杂、高性能部件提供了极致的均匀性。