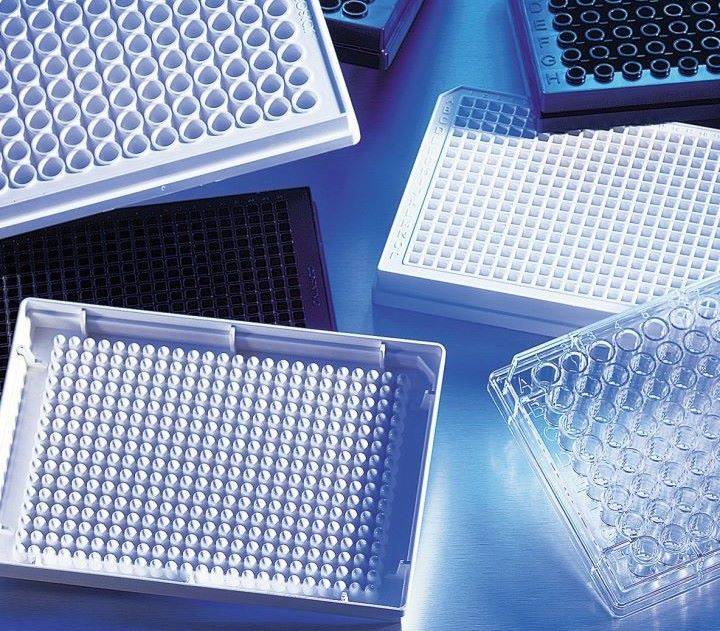

微孔板的分类

孔密度

微孔板有一系列孔密度,包括 6、12、24、48、96、384、1536 和 3456 孔。这些变化可满足不同的实验需求,在样品量、试剂效率和操作复杂性之间取得平衡。

密度较高的板,如 1536 孔或 3456 孔板,可显著减少每次实验所需的试剂量。这种减少尤其有利于高通量筛选和其他资源密集型应用。然而,密度的增加要求使用自动移液系统来准确有效地处理较小的体积。

相反,密度较低的平板,如 6 孔或 12 孔的平板,通常是需要较大样品量的实验或无法从高通量功能中获益的实验的首选。这些平板更易于人工操作,因此适用于尚未要求自动化的小规模实验或初始测试阶段。

因此,孔密度的选择是一个关键的考虑因素,需要在成本效益和操作效率与实验设置的复杂性之间取得平衡。

材料

在为实验室应用选择微孔板时,材料的选择至关重要,因为它直接影响到透光率、自发荧光和各种检测的整体适用性等关键性能指标。生产微孔板的常用材料包括聚碳酸酯(PC)、聚苯乙烯(PS)和环烯烃共聚物(COC)。这些材料各有其独特的优势和利弊,因此适用于不同的实验需求。

聚碳酸酯(PC)以其高抗冲击性和热稳定性著称,因此非常适合 PCR 等需要较大温度变化的应用。不过,众所周知,与其他材料相比,聚碳酸酯会产生较高的自发荧光,这在敏感的荧光检测中可能是一个缺点。

聚苯乙烯(PS)是一种多功能材料,因其成本效益高和良好的光学特性而被广泛使用。它具有适度的透射率和相对较低的自发荧光,因此适合广泛的应用,包括 ELISA 和光学测试。不过,PS 的耐用性不如 PC,在高温下容易变形。

环烯烃共聚物(COC)因其出色的光学清晰度和低自发荧光而备受推崇,是高灵敏度荧光和发光检测的首选材料。COC 还具有良好的耐化学性和热稳定性,但价格通常高于 PC 和 PS。

总之,微孔板材料的选择应以实验室应用的具体要求为指导,同时兼顾透光率、自发荧光、热稳定性和成本等因素。下表对这些材料进行了快速比较:

| 材料 | 透光率 | 自发荧光 | 热稳定性 | 成本 |

|---|---|---|---|---|

| 聚碳酸酯 (PC) | 中等 | 高 | 高 | 中等 |

| 聚苯乙烯 (PS) | 好 | 低 | 中度 | 低 |

| 环烯烃共聚物 (COC) | 优 | 极低 | 好 | 高 |

了解这些特性有助于研究人员在选择微孔板时做出明智的决定,以满足其特定的实验室需求。

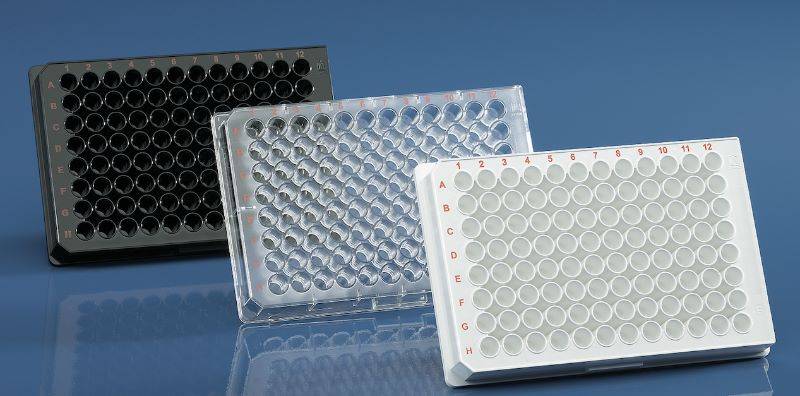

颜色

微孔板有多种颜色,包括透明、黑色、白色和灰色。颜色的选择会极大地影响检测数据的质量,尤其是在荧光和发光检测中。

-

透明微孔板:适用于要求最大透光率的应用,如光密度(OD)测量和传统的吸光度检测。由于其透明度高,也适用于显微镜检查。

-

黑色微孔板:适用于对背景噪声要求极高的荧光检测。黑色可吸收杂散光,提高信噪比,提高荧光读数的准确性。

-

白色微孔板:常用于需要将发射光反射回检测器的发光检测。白色提供了一个高反射表面,可提高发光测量的灵敏度。

-

灰色微孔板:通常用于需要在光吸收和反射之间取得平衡的应用。尤其适用于需要同时进行荧光和发光测量的检测。

为微孔板选择合适的颜色对于优化实验结果至关重要。每种颜色都具有独特的优势,可满足特定的检测要求,确保获得更可靠、更准确的数据。

孔形

微孔板是实验室工作流程中不可或缺的一部分,有各种孔型,旨在优化特定的实验需求。两种主要的孔形是 圆形 和 方形 两种主要孔形是圆形和方形,每种孔形都有其独特的优势和利弊。

圆形孔

- 样品量:圆孔特别有利于处理较大的样品量,是需要大量使用试剂的应用场合的理想选择。

- 透光性:圆孔的几何形状可确保均匀的透光性,这对于依靠分光光度法和荧光法进行的检测至关重要。

- 混合效率:圆形边缘有利于更好地混合,提高了需要彻底均质的反应的效率。

方形孔

- 样品量:方形孔更节省空间,在相同的孔板面积内可实现更高的孔密度,这对于需要多个较小样品的应用非常有利。

- 透光性:虽然方形孔的均匀性略逊于圆形孔,但仍能为大多数光学检测提供足够的透光性。

- 混合效率:方形孔的尖角可产生局部湍流,有助于混合粘性或含颗粒的样品。

选择圆形还是方形孔取决于实验的具体要求,在样品量、透光率和混合效率等因素之间取得平衡,以获得最佳结果。

底部形状

微孔板有各种底部形状,每种形状都是为优化特定的实验室应用而设计的。最常见的底部形状包括扁平、锥形、圆形和弧形。这些形状不仅仅是外观上的,它们对实验的性能和准确性有很大影响。

-

平底:非常适合以下应用 分光光度法 和 ELISA (酶联免疫吸附试验)等应用的理想选择,平底提供了稳定的表面,可进行精确的透光率和吸光度测量。它们还适用于对光学读数精确度要求极高的高通量筛选。

-

锥形底部:特别适用于 混合 和 离心 .锥形有利于更好地混合试剂,也更容易清除上清液,因此在需要高效液体处理的应用中是首选。

-

圆形底部:常用于 细胞培养 应用中,圆底可模仿细胞的自然环境,促进细胞更好地附着和生长。它们在微孔板阅读器中也很有优势,因为弧度有助于光线在孔内均匀分布。

-

弧形底部:与圆形底部类似,弧形底部适用于 细胞检测 和 荧光检测 .弧度有助于光的分散,提高荧光读数的清晰度和精确度。

| 底部形状 | 应用 | 优势 |

|---|---|---|

| 扁平 | 分光光度法、ELISA | 表面稳定,可获得准确的光学读数 |

| 锥形 | 混合、离心 | 便于更好地混合和清除上清液 |

| 圆形 | 细胞培养 | 模拟自然细胞环境,更好地附着 |

| 弧形 | 基于细胞的检测,荧光 | 增强光散射,读数更清晰 |

因此,底部形状的选择对于确保各种实验室实验的成功和可靠性至关重要,反映了不同科学应用的细微需求。

表面处理

微孔板的表面处理在决定微孔板与样品之间的相互作用方面起着至关重要的作用,从而影响生化和细胞检测的结果。这些处理方式从无结合到高结合不等,根据具体应用的不同,每种处理方式都具有不同的优势和局限性。

例如 无结合表面 非常适合需要尽量减少非特异性相互作用的应用,如蛋白质检测。这些表面可降低蛋白质粘附在孔上的风险,确保结果更准确、更可重现。另一方面 高结合表面 可增强细胞或生物分子的附着力,因此适用于需要强附着力的细胞检测。

| 表面处理 | 应用 | 优点 |

|---|---|---|

| 不结合 | 蛋白质检测 | 最大程度地减少非特异性相互作用 |

| 高结合 | 基于细胞的检测 | 增强细胞或生物分子的附着力 |

表面处理的选择会对微孔板的性能产生重大影响,因此必须根据实验室应用的具体要求进行仔细考虑。

应用和注意事项

ELISA 和光学应用

96 孔板因其高密度和与自动移液系统的兼容性而成为 ELISA(酶联免疫吸附试验)的行业标准。这些孔板的设计优化了试剂的使用,最大限度地减少了样品浪费,是研究和诊断领域高通量筛选的理想选择。

对于光学应用,包括显微镜和各种光谱测试,首选透明材料,如聚苯乙烯(PS)和环烯烃共聚物(COC)。这些材料具有优异的透光性,自发荧光极少,可确保在光敏检测中读数准确。这些材料的透明度对于需要通过平板透光的应用(如吸光度和荧光测量)至关重要。

| 材料 | 透光率 | 自发荧光 | 适合光学应用 |

|---|---|---|---|

| 聚苯乙烯 (PS) | 高 | 低 | 适用于显微镜和光谱学 |

| 环烯烃共聚物 (COC) | 极高 | 极低 | 高精度光学测试的理想选择 |

光学应用中材料的选择不仅关系到透明度,还影响到测试的整体性能和可靠性。例如,COC 以其极低的自发荧光而著称,是单分子检测和高级荧光显微镜等需要高灵敏度的检测的首选。

PCR 应用

聚合酶链反应 (PCR) 板是专为满足聚合酶链反应 (PCR) 过程的严格要求而设计的,该过程涉及显著的温度波动。这些板通常由聚碳酸酯 (PC) 和聚丙烯 (PP) 制成,这些材料以热稳定性和耐用性著称。选择这些材料可确保平板能够承受变性所需的高温以及退火和延伸阶段所需的低温。

| 材料 | 特性 | PCR 中的应用 |

|---|---|---|

| 聚碳酸酯 | 高热稳定性、良好的光学清晰度、耐机械应力 | 适用于高通量 PCR、实时 PCR 和其他对温度敏感的检测 |

| 聚丙烯 | 出色的耐化学性、低吸湿性和良好的热性能 | 是标准 PCR、PCR 产物长期储存和冻融循环的理想选择 |

除了材料特性外,PCR 培养板通常还具有薄壁和低热量等特殊设计,有助于保持整个培养板的温度分布均匀。这种均匀性对于确保目标 DNA 序列的一致和准确扩增至关重要。此外,这些板的表面通常经过处理,以最大限度地减少非特异性结合,从而提高 PCR 产物的纯度和产量。

选择 PCR 板时,必须考虑检测的具体要求,包括自动化需求、试剂量和检测方法的灵敏度。例如,高通量实验室可能更喜欢孔密度较高且与自动移液系统兼容的板,而专注于实时 PCR 的研究实验室可能会优先考虑光学清晰度和低自发荧光。

细胞分析

对于基于细胞的分析,由于细胞生长和观察的特殊要求,微孔板的选择至关重要。非无菌微孔板必须经过严格的无菌处理,以防止污染,确保有一个有利于细胞存活和增殖的受控环境。这些平板的表面必须是亲水性的,以利于细胞的牢固附着和最佳的生长条件。

透明底部在基于细胞的检测中是不可或缺的,因为它能让研究人员从底部读取细胞活动,提供清晰无阻的视野。这一特点在高通量筛选和活细胞成像中尤为有利,因为在这些应用中,持续监测和精确测量是必不可少的。

| 要求 | 描述 |

|---|---|

| 无菌处理 | 防止污染;确保细胞生长的无菌环境。 |

| 亲水性表面 | 增强细胞附着和增殖;支持细胞的最佳生长。 |

| 透明底部 | 允许自下而上的清晰读数;对高通量筛选至关重要。 |

酶标仪

为酶标仪选择微孔板时,必须考虑微孔板尺寸和孔位的变化对数据准确性的影响。这些变化会带来很大的误差,尤其是在高通量筛选和敏感检测中。

例如,不同规格微孔板上孔的位置会导致移液准确性和均匀性的差异。这在需要精确配料和一致混合的检测中尤为重要。此外,孔的大小也会影响试剂的用量,进而影响结果的灵敏度和可靠性。

为了减少这些问题,必须仔细选择和校准微孔板。这包括选择具有标准化孔尺寸和位置的微孔板,并确保仪器经过校准,能够处理这些特定的微孔板格式。为了长期保持数据的完整性,定期校准检查也是必要的。

此外,微孔板材料的选择也会影响酶标仪的性能。聚苯乙烯(PS)和环烯烃共聚物(COC)等材料因其光学清晰度高、自发荧光低而受到青睐,这对于基于荧光的检测中准确读数至关重要。

总之,微孔板的精心选择和校准对于确保酶标仪生成数据的准确性和可靠性至关重要。这一过程不仅要考虑孔的大小和位置,还要考虑微孔板的材料特性,以优化检测性能。