从根本上说,低温研磨用于在室温下难以或不可能减小尺寸的材料。通过使用液氮等低温剂,该过程将材料冷却至极度脆化。这种脆化作用使得材料能够有效地破碎成精细、均匀的颗粒,从而防止熔化、粘连或热敏组件降解等问题。

低温研磨的主要目的不仅仅是使材料变冷,而是暂时改变其物理特性,使其从延展和坚韧变为坚硬和脆性。这种转变克服了传统研磨中常见的故障,如热损伤、设备堵塞和颗粒尺寸不一致。

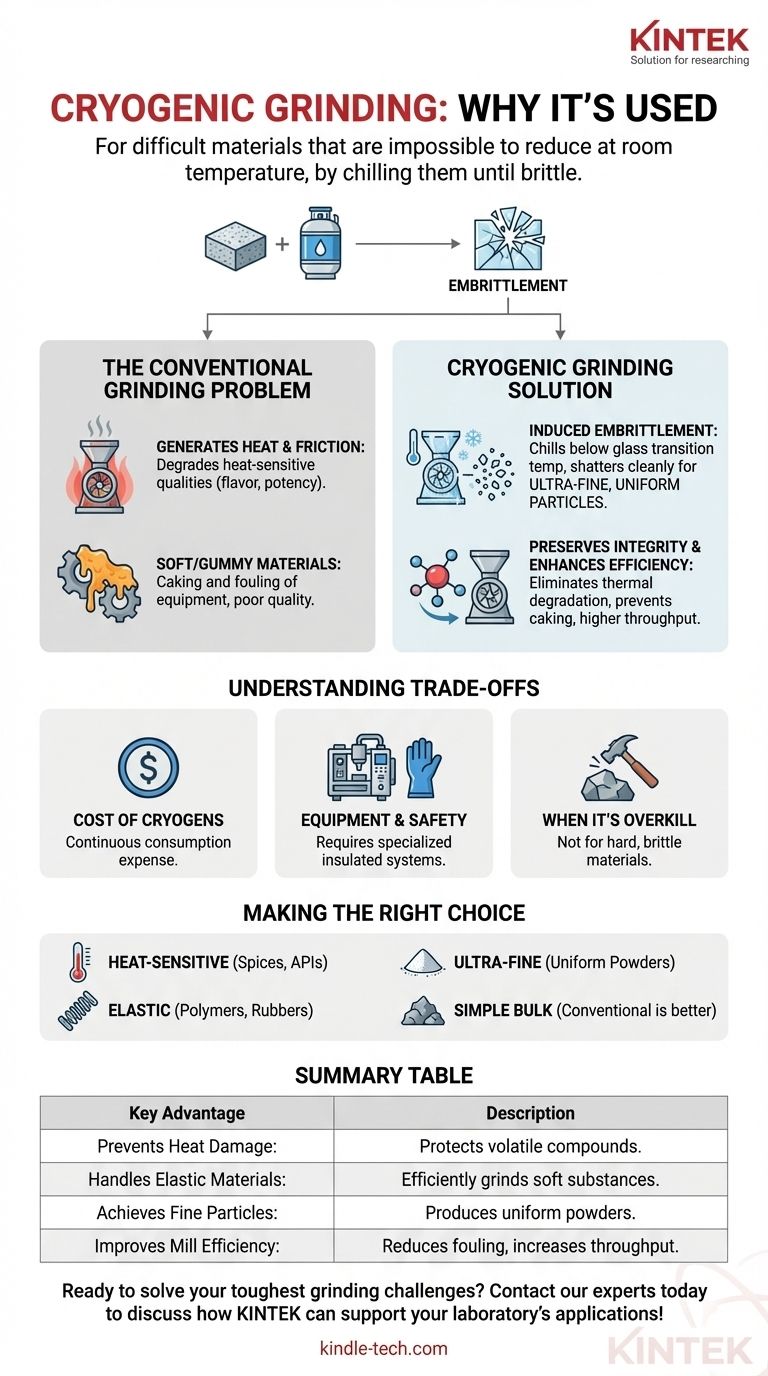

传统研磨的基本问题

标准的研磨方法依靠机械力——冲击、剪切或压缩——来分解材料。虽然这对许多物质有效,但这个过程会产生大量的摩擦和热量。

热量产生及其后果

研磨的巨大能量大部分转化为热量。对于香料、药品或某些聚合物等热敏材料,这可能会降解或破坏您希望保留的特性,例如风味、香气或化学效力。

软性或粘性材料的挑战

许多材料,特别是塑料、弹性体和蜡,在环境温度下不易研磨。它们不会破碎,而是在研磨机的应力下变软、变粘或变有弹性。这会导致设备结块和堵塞,降低产量,并影响颗粒质量。

低温研磨如何解决问题

低温研磨通过将极度低温引入过程,从根本上改变材料的行为方式,直接解决了热量和延展性的限制。

脆化原理

将材料冷却到其玻璃化转变温度以下,使其失去延展性,变得脆而像玻璃一样。当施加研磨力时,脆化的材料会干净利落地瞬间破碎。这是实现超细和高度均匀颗粒的关键。

保持产品完整性

由于整个系统都充满了液氮等惰性低温剂,热量会立即被吸收。这消除了热降解,保护了热敏成分的质量。它还通过置换氧气来防止氧化,进一步保持最终产品的完整性。

提高研磨机效率

通过防止材料变粘,低温研磨消除了产品在研磨机内部的结块。这使得生产率显著提高,单位产品的能耗降低,并减少了研磨部件的磨损。该过程更快,并且减少了停机清洁的时间。

了解权衡和注意事项

尽管低温研磨功能强大,但它是一个具有特定要求的专业过程。它并非适用于所有研磨任务的通用解决方案。

低温剂的成本

主要的运行成本是液氮或其他低温剂的持续消耗。这项费用必须通过增加的价值来证明,例如改善的产品质量或处理原本不可能处理的材料的能力。

设备和安全复杂性

低温系统需要绝缘机械、专业处理设备以及处理极冷物质的严格安全规程。与传统研磨设备相比,初始资本投资和操作复杂性更高。

何时是“杀鸡用牛刀”

对于在室温下容易研磨的坚硬、易碎材料(例如矿物、盐或陶瓷),低温研磨没有明显的优势,只会增加不必要的成本和复杂性。

为您的应用做出正确的选择

选择正确的研磨方法完全取决于您的材料特性和最终产品目标。

- 如果您的首要重点是保护热敏特性:低温研磨对于保护香料、食品和活性药物成分 (API) 中易挥发的化合物至关重要。

- 如果您的首要重点是加工软性或弹性材料:对于否则会熔化或堵塞设备的聚合物、橡胶、蜡和粘合剂,低温研磨是更优越的方法。

- 如果您的首要重点是获得超细、均匀的粉末:脆化过程可以实现传统方法通常无法达到的粒度控制和一致性水平。

- 如果您的首要重点是对简单材料进行成本效益高的批量还原:对于不热敏或非延展的材料,传统研磨仍然是最经济和最直接的选择。

通过为了减小尺寸的目的从根本上改变材料的物理状态,低温研磨开启了其他方法无法实现的处理能力。

总结表:

| 关键优势 | 描述 |

|---|---|

| 防止热损伤 | 保护香料、药品和聚合物中易挥发的化合物。 |

| 处理弹性材料 | 有效研磨塑料和橡胶等柔软、粘性的物质。 |

| 获得精细颗粒 | 通过材料脆化生产超细、均匀的粉末。 |

| 提高研磨机效率 | 减少设备堵塞,提高产量,降低能耗。 |

准备好解决您最棘手的研磨挑战了吗?如果您处理的是对热敏感的香料、药品、聚合物或其他难以研磨的材料,KINTEK 的低温研磨解决方案可以保护您的产品质量并提高您的工艺效率。我们在实验室设备方面的专业知识可确保您获得满足需求的正确系统。立即联系我们的专家,讨论我们如何支持您实验室的研磨应用!

图解指南