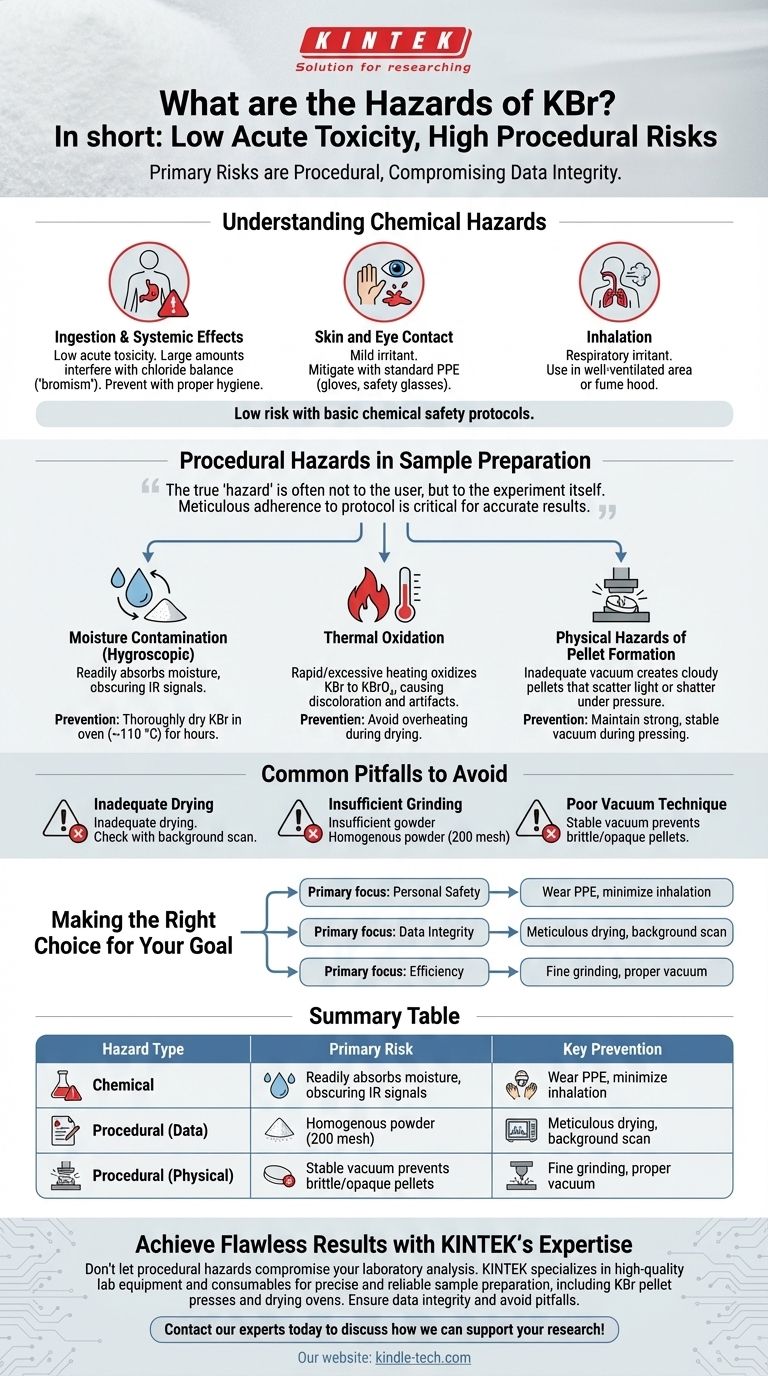

简而言之,溴化钾(KBr)是一种急性毒性较低的盐,但在实验室环境中,其主要危害在于操作规程。虽然它接触皮肤可能引起轻微刺激,大量摄入有害,但更常见的风险是样品制备过程中的操作失误——例如使用潮湿的材料或过度加热——这些失误会损害您结果的完整性。

使用KBr的真正“危害”往往不是对用户,而是对实验本身。虽然基本的化学安全是必要的,但严格遵守制备规程是获得准确、可重复结果的最关键因素。

了解化学危害

虽然KBr的危险性不高,但遵循标准的实验室安全规程至关重要。它的风险与许多常见的实验室盐类相似。

摄入与全身影响

KBr的急性毒性水平较低。然而,摄入大量KBr会干扰身体的氯平衡,并可能导致一种称为“溴中毒”的状况,症状包括抑郁、意识模糊和神经系统问题。只要保持适当的实验室卫生,这不是一个风险。

皮肤和眼睛接触

作为一种盐,KBr可能对皮肤造成轻微刺激,对眼睛的刺激性更强。佩戴标准个人防护装备(PPE),包括手套和安全眼镜,足以减轻这种风险。

吸入

吸入KBr粉末可能刺激呼吸道。在通风良好的区域处理细粉或在转移时使用通风橱可以防止这种情况。

样品制备中的操作危害

对于红外(IR)光谱等应用来说,最显著的“危害”是破坏样品和使数据无效的操作错误。这些是在实践中需要最关注的风险。

湿气污染的风险

KBr是吸湿性的,这意味着它很容易从空气中吸收水分。如果使用潮湿的KBr制作压片,其中夹带的水分会在您的红外光谱中产生宽而强的吸收峰,可能掩盖您实际样品的信号。

这就是为什么在使用前,KBr必须在约110°C的烘箱中彻底干燥数小时的原因。

热氧化的危害

虽然干燥至关重要,但对KBr进行快速或过度加热可能导致其氧化成溴酸钾(KBrO₃)。

这种不希望发生的化学变化会导致压片变色,并在分析中引入伪影。它对空白样的化学纯度和结果的准确性构成了危害。

压片过程中的物理危害

制作KBr压片需要高压机和真空来去除捕获的空气。真空不足会导致压片浑浊、不透明,从而散射光线,降低光谱质量。

更重要的是,制备不良或易碎的压片在压力下可能会碎裂,这是一种轻微的物理安全风险,也是浪费时间和样品材料的主要原因。

应避免的常见陷阱

成功使用KBr需要平衡相互竞争的操作要求。避免这些常见错误是关键。

干燥不足

KBr粉末干燥不充分是最常见的错误。务必使用仅由干燥的KBr制成的压片进行背景测量,以检查水分污染的特征性宽峰。

研磨不充分

KBr和样品必须研磨成极其细致、均匀的粉末(理想情况下为200目或更细)。粗颗粒会导致光散射,从而引起基线倾斜和光谱质量不佳。

真空技术不佳

在没有保持强大、稳定的真空的情况下施加压力是一个常见错误。捕获的空气会使压片变脆且不透明,从而影响测量并增加压片在处理过程中破裂的风险。

根据您的目标做出正确的选择

您的安全和操作重点取决于您想要实现的目标。

- 如果您的主要重点是人身安全: 佩戴标准PPE(手套和安全眼镜),并以最小化吸入的方式处理粉末。

- 如果您的主要重点是数据完整性: 优先彻底干燥KBr粉末,并对仅含KBr的压片进行背景扫描,以确认没有水分。

- 如果您的主要重点是效率: 确保您的KBr研磨得很细,并使用正确的真空技术,以避免不得不重做破裂或不透明的压片。

最终,掌握处理KBr的程序是确保人身安全和实验成功的关键。

摘要表:

| 危害类型 | 主要风险 | 关键预防措施 |

|---|---|---|

| 化学 | 轻微的皮肤/眼睛刺激,摄入有害 | 佩戴标准PPE(手套、安全眼镜) |

| 操作(数据) | 水分污染、热氧化、压片形成不良 | 彻底干燥KBr,避免过热,使用正确的真空技术 |

| 操作(物理) | 压片在压力下碎裂 | 确保压制过程中真空稳定 |

借助KINTEK的专业知识实现完美结果

不要让操作危害损害您的实验室分析。KINTEK专注于提供您进行精确可靠的样品制备所需的高质量实验室设备和耗材,包括KBr压片机和干燥箱。我们的产品旨在帮助您避免水分污染和热氧化等常见陷阱,确保您的红外光谱数据的完整性。

无论您是建立新实验室还是优化当前流程,KINTEK都是您所有实验室需求的可靠合作伙伴。

立即联系我们的专家,讨论我们如何支持您的研究并确保您的成功!

图解指南