薄膜沉积部件

用于薄膜沉积的镀铝陶瓷蒸发舟

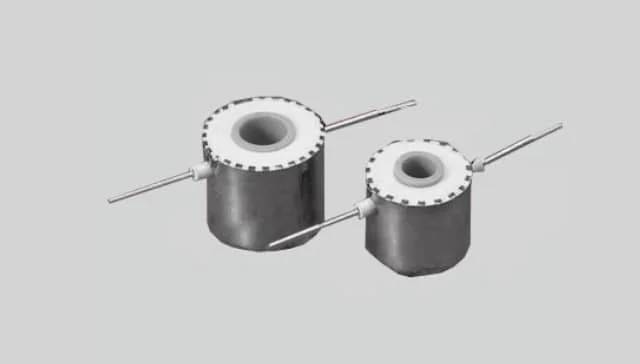

货号 : KME-DL

价格根据 规格和定制情况变动

- 材料

- 陶瓷

- 容量

- 1 毫升 / 3 毫升 / 5 毫升

运输:

联系我们 获取运输详情 享受 准时发货保证.

为什么选择我们

简易的订购流程、优质的产品和专业的支持,助力您的业务成功。

应用

蒸发舟内部涂有一层铝或其他具有优异耐热性和耐化学性的金属,以提高其热性能并促进高效蒸发。陶瓷蒸发舟上的镀铝涂层有多种用途。首先,它起到反射表面的作用,通过将热量反射回待蒸发的材料来提高热效率。这有助于优化沉积过程并降低能耗。陶瓷蒸发舟具有特殊的电学和热学性能,是满足严格要求的真空镀铝的理想材料。

- 导电陶瓷材料。

- 铝电解槽的阴极涂层材料。

- PTC加热陶瓷材料和柔性PTC材料。

- 总之,各种薄膜沉积过程的容器,特别是真空蒸发系统。常用于半导体制造、光学、电子、表面涂层等行业。

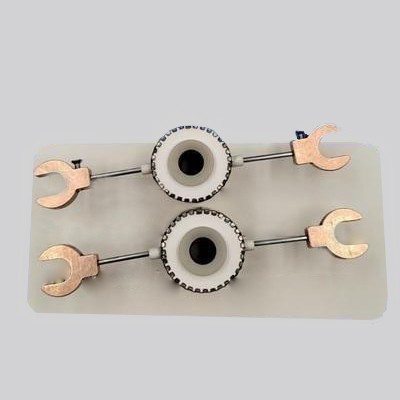

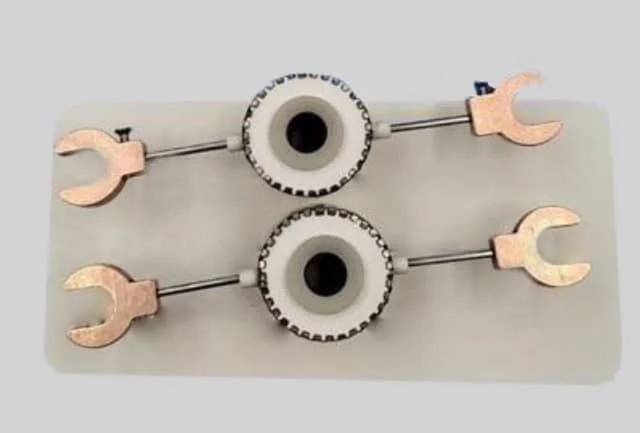

细节与零件

我们展示的坩埚有不同尺寸可供选择,也可根据要求定制尺寸。

优点

- 良好的化学稳定性

- 优异的抗热震性和抗弯曲性

- 熔融铝易于均匀铺展。

- 蒸发均匀,加热速度快,蒸发效率高

- 良好的耐熔融铝或其他熔融金属腐蚀性,延长了蒸发舟的使用寿命。

行业领军企业信赖之选

FAQ

镀铝陶瓷蒸发舟的特点。

4.8 / 5

I was impressed with the fast delivery of my order. The evaporation boats arrived in perfect condition and were exactly as described.

4.7 / 5

The aluminized ceramic evaporation boats are a great value for the money. They are well-made and have held up well under heavy use.

4.9 / 5

The quality of the evaporation boats is top-notch. They are made from high-quality materials and are very durable.

4.6 / 5

I have been using these evaporation boats for several months now and they have shown no signs of wear or tear. They are a great investment.

4.8 / 5

The technological advancements in these evaporation boats are impressive. They are very efficient and have helped me to improve the quality of my work.

4.7 / 5

I am very satisfied with these evaporation boats. They are a great addition to my lab and have helped me to streamline my work.

4.9 / 5

These evaporation boats are a game-changer. They have made my work so much easier and more efficient.

4.6 / 5

I would highly recommend these evaporation boats to anyone who is looking for a high-quality and durable product.

获取报价

我们的专业团队将在一个工作日内回复您。请随时与我们联系!

相关产品

钼钨钽蒸发舟,适用于高温应用

蒸发舟源用于热蒸发系统,适用于沉积各种金属、合金和材料。蒸发舟源有不同厚度的钨、钽和钼可供选择,以确保与各种电源兼容。作为容器,它用于材料的真空蒸发。它们可用于各种材料的薄膜沉积,或设计为与电子束制造等技术兼容。

用于微波等离子体化学气相沉积和实验室金刚石生长的圆柱形谐振腔MPCVD设备系统反应器

了解圆柱形谐振腔MPCVD设备,这是一种用于珠宝和半导体行业中生长金刚石宝石和薄膜的微波等离子体化学气相沉积方法。了解其相对于传统HPHT方法的成本效益优势。

相关文章

薄膜沉积中蒸发和溅射技术的比较研究

最常用的两种薄膜沉积技术是蒸发和溅射。

真空镀膜综合指南》:提高性能和美感

探索真空镀膜的世界,这是一种在金属和塑料表面形成保护层和美观层的工艺。探索真空镀膜的类型、用途和优点,包括提高性能、延长使用寿命和改善美观度。

了解真空镀膜中的蒸发舟

深入了解真空镀膜工艺中的蒸发舟、材料、布置、温度控制和腐蚀问题。

用于电池涂层的 PECVD 石墨舟

探索在 PECVD 中使用石墨舟实现高效电池涂层。

蒸发涂层的蒸发源类型

探索薄膜沉积中使用的不同蒸发源,包括灯丝、坩埚和蒸发舟。

旋转蒸发仪及其在中药提炼中的应用

探讨旋转蒸发仪在浓缩和提炼传统中药提取物中的应用,详细介绍设备选择、操作原理和安全注意事项。