在X射线荧光(XRF)分析中,误差源于三个主要领域:样品本身(物理和化学性质)、仪器的硬件和稳定性,以及所使用的分析方法或校准。虽然样品制备过程中的污染等因素很重要,但真正准确的结果取决于对这三个领域中所有变量的控制。

您的XRF测量准确性不仅取决于光谱仪的质量,还直接反映了您对样品物理和化学变化以及分析校准稳健性的控制程度。

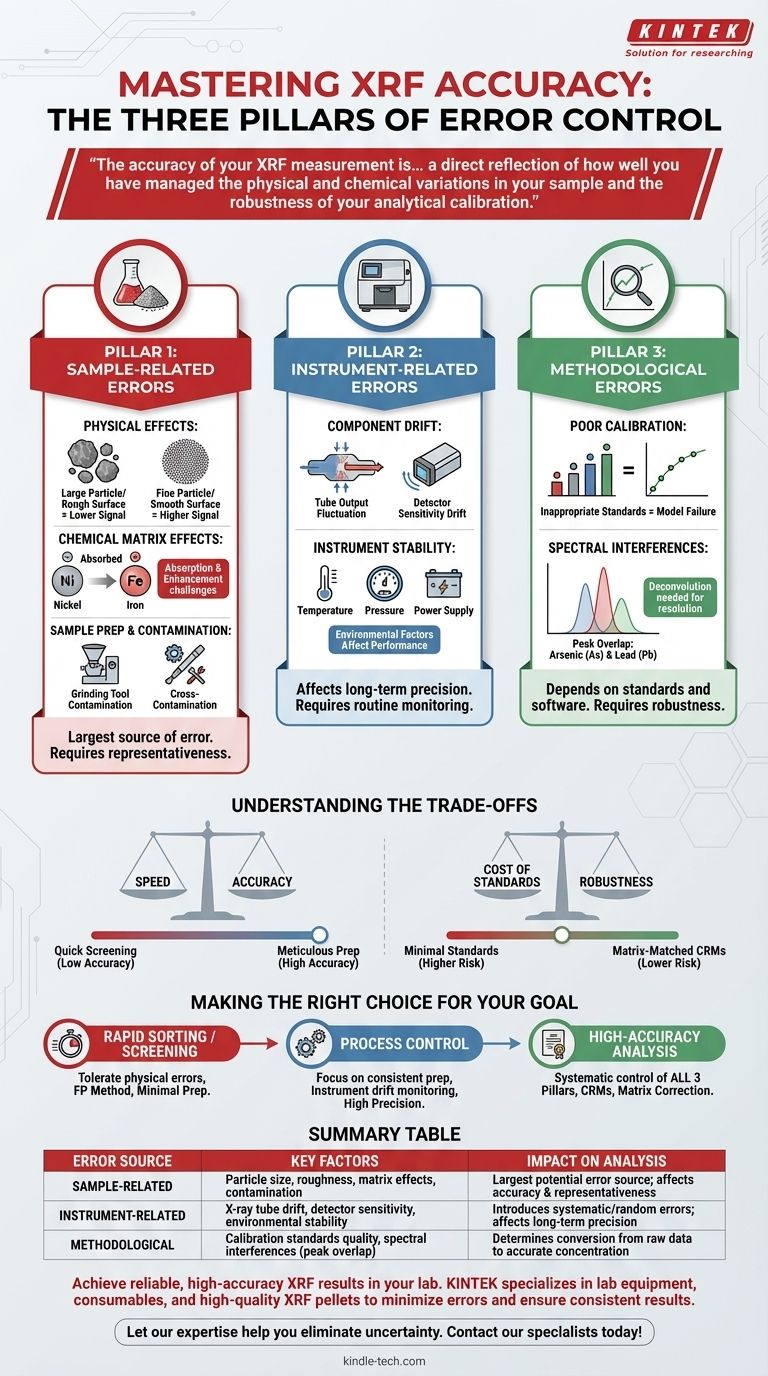

XRF误差的三大支柱

为了获得可靠的结果,您必须了解潜在的误差引入点。我们可以将这些来源分为三个不同的类别。

支柱 1:与样品相关的误差

这通常是最大的误差来源。光谱仪只能测量呈现给它的样品;如果样品不能真实代表主体材料,结果就会有缺陷。

物理效应

样品的物理性质极大地影响X射线信号。关键因素包括粒度、表面粗糙度和样品均匀性。

较细的颗粒通常比较大的颗粒产生更强的荧光信号。不一致的研磨或粗糙的表面可能导致显著的、不可预测的误差。

化学基体效应

这指的是样品中其他元素如何吸收或增强您试图测量的元素的X射线。这是XRF中的一个基本挑战。

例如,高浓度的铁会严重吸收镍的荧光,使镍的浓度看起来低于其实际浓度。这些效应必须通过数学方法进行校正。

样品制备和污染

样品制备的方式是一个关键的控制点。由此引入的错误是不可逆的。

如前所述,来自研磨设备的污染可能会引入外来元素。同样,如果制备工具在每次使用之间没有彻底清洁,可能会发生样品间的交叉污染。

支柱 2:与仪器相关的误差

尽管现代XRF光谱仪非常稳定,但它们并非完美无缺。硬件变化可能会向分析中引入系统性或随机误差。

部件漂移

两个最关键的部件,即X射线管和探测器,可能会随着时间推移出现性能变化。

灯管的输出强度可能会波动,而探测器的灵敏度可能会因温度变化或老化而漂移。这些变化通常是缓慢的,可以通过定期监测来控制。

仪器稳定性

诸如环境温度、大气压力(在某些系统中)和电源稳定性等因素会影响光谱仪的性能。

为仪器维护一个受控的环境对于实现高精度、长期的分析结果至关重要。

支柱 3:方法和校准误差

即使样品完美、仪器稳定,最终结果也完全取决于分析方法和校准的质量。

不良校准

校准是将原始X射线强度转换为元素浓度的数学模型。该模型的好坏取决于用于创建它的标准物质。

使用不足或不合适的校准标准物质,这些标准物质与未知样品的化学基体不匹配,是主要分析误差的首要来源。

光谱干扰

有时,两种不同元素的特征X射线谱线靠得太近,以至于探测器无法分辨它们。这被称为峰重叠。

例如,砷的K-alpha线与铅的K-beta线重叠。需要复杂的软件来在数学上解卷积这些峰,并报告每种元素的准确结果。

理解权衡

控制每一种误差来源可能既耗时又昂贵。关键在于使您的制备和分析的严谨程度与您的特定目标相匹配。

速度与准确性

对未制备样品进行快速的“即时”分析可能足以进行简单的材料识别或筛选。

然而,这种方法会牺牲准确性,完全不适用于质量控制或法规遵从性,在这些领域,一丝不苟的样品制备(如研磨和压制样品片)是不可或缺的。

标准成本与稳健性

创建稳健的校准需要大量的、与基体匹配的优质认证参考材料,这可能很昂贵。

使用最少量的标准物质或依赖“类型标准化”(用一两个本地样品调整出厂校准)成本较低,但如果您的样品偏离标准物质,则会带来更高的误差风险。

为您的目标做出正确的选择

您的分析策略应由您需要回答的问题决定。

- 如果您的主要重点是快速材料分类或筛选: 您通常可以容忍物理效应带来的误差,并使用简单的基本参数(FP)方法,最大限度地减少样品制备。

- 如果您的主要重点是已知材料类型的过程控制: 您的主要关注点是精度,因此请专注于高度一致的样品制备和定期的仪器漂移监测。

- 如果您的主要重点是用于认证或研究的高精度分析: 您必须系统地解决所有三个支柱,使用一丝不苟的样品制备、用于校准的认证参考材料以及基体校正软件。

最终,在XRF中实现准确性是一个系统控制的过程,了解潜在的误差来源是消除它们的第一步。

摘要表:

| 误差来源 | 关键因素 | 对分析的影响 |

|---|---|---|

| 与样品相关 | 粒度、表面粗糙度、化学基体效应、污染 | 最大的潜在误差来源;影响结果的准确性和代表性 |

| 与仪器相关 | X射线管漂移、探测器灵敏度、环境稳定性 | 引入系统性或随机误差;影响长期精度 |

| 方法学 | 校准标准物质质量、光谱干扰(峰重叠) | 决定了从原始数据到准确浓度值的转换 |

在您的实验室中实现可靠、高精度的XRF结果。

实现精确分析的途径需要控制样品、仪器和方法中的变量。KINTEK 专注于实验室设备和耗材,通过高质量的XRF样品片、压片机和配件来满足实验室需求,这些产品旨在最大限度地减少样品制备误差并确保结果一致。

让我们的专业知识帮助您消除不确定性。 立即联系我们的专家,讨论您的具体应用以及我们如何支持您的分析目标。

图解指南