在理想条件下, X射线荧光(XRF)是一种高度准确和精确的分析技术。对于经过良好制备、均匀的样品并使用特定校准时,通常可以实现结果与真实值在1-5%以内的准确度,而精度(重复性)通常优于0.1%。然而,这种准确性并非仪器固有的;它在很大程度上取决于您方法学的质量。

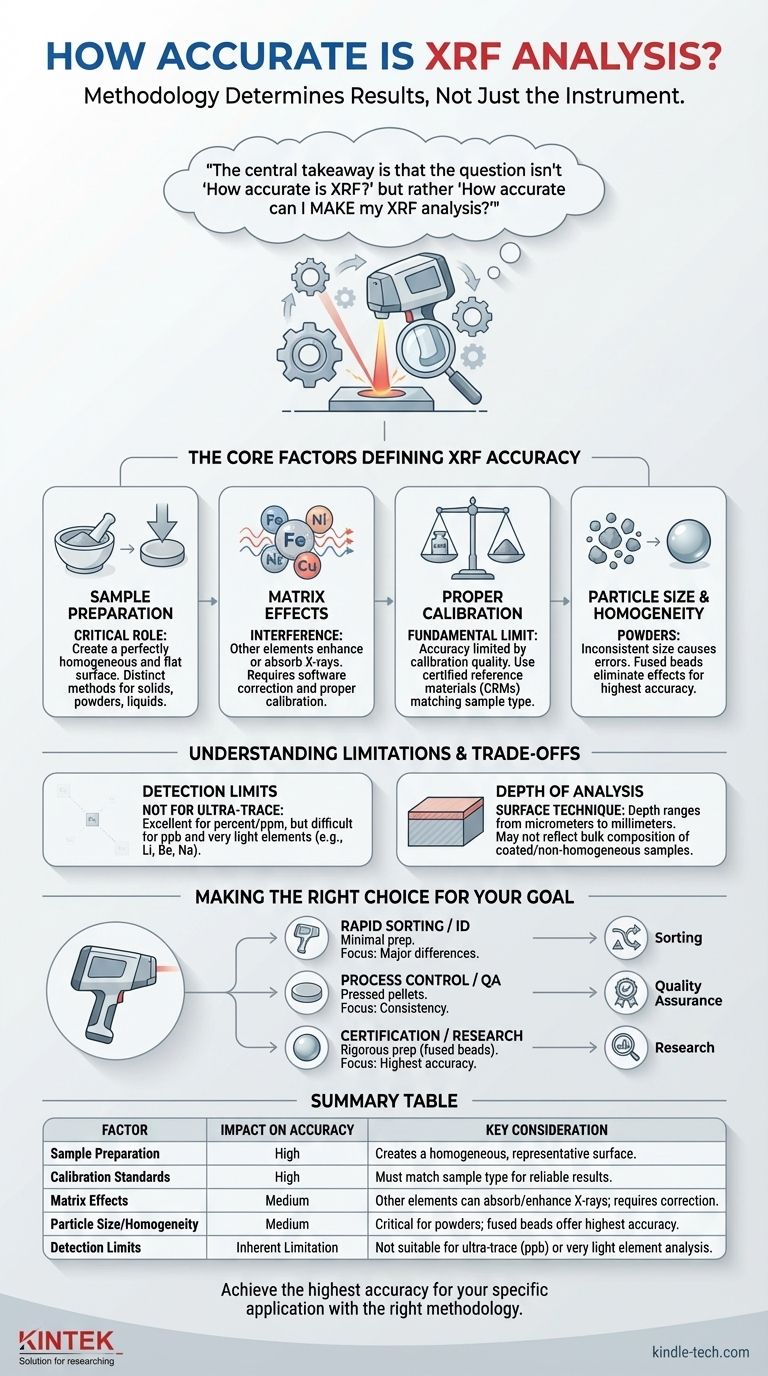

核心要点是,问题不在于“XRF的准确度有多高?”,而在于“我能使我的XRF分析的准确度达到多高?”您结果的准确性不是机器的一个固定属性,而是您的样品制备、校准以及对样品本身的理解的直接结果。

决定XRF准确性的核心因素

XRF测量的最终准确性是几个相互依赖因素的函数。理解这些要素是生成可靠且可信赖数据的关键。

样品制备的关键作用

这是您可以控制的单一最重要的因素。XRF光束只分析样品表面的一个非常薄的层,因此该表面必须完美地代表整个样品。

制备的目标是为分析仪创建一个完全均匀且平坦的表面。正如提供的参考资料所示,不同类型的样品(固体、粉末、液体)需要不同的制备方法,以最大限度地减少误差并确保测量可靠。

理解基体效应

样品很少只由单一元素组成。当样品中存在其他元素(即“基体”)增强或吸收您试图测量的元素的X射线时,就会发生基体效应。

例如,高浓度的铁会吸收镍的荧光X射线,使得镍的浓度看起来比实际要低。现代XRF软件具有校正这些效应的算法,但它们依赖于正确的校准。

正确校准的重要性

XRF仪器将未知样品的X射线信号与具有已知元素浓度的认证参考物质(CRMs)的信号进行比较。您的准确性从根本上受到您的校准质量的限制。

如果您正在分析不锈钢,则必须使用涵盖预期浓度范围的不锈钢标准品进行校准。使用土壤或塑料标准品来测量金属合金将产生高度不准确的结果。

粒径和均匀度的影响

在粉末样品中,不一致的粒径会导致显著误差。较大的颗粒可能会遮挡X射线光束对较小颗粒的照射,并且不同的矿物可能研磨程度不同,从而导致样品表面不具有代表性。

这就是为什么像制作熔融珠(将样品溶解在玻璃中)这样的方法通常能为粉末带来最高的准确度,因为它们消除了所有粒径和矿物学效应。

理解局限性和权衡

没有一种分析技术是完美的。成为值得信赖的顾问意味着要承认XRF存在固有局限性的领域。

检测限

虽然XRF在测量百分比或百万分之一(ppm)范围内的元素方面非常出色,但它并非为超痕量分析(十亿分之一)而设计。此外,它在检测非常轻的元素(如锂、铍或钠)方面存在困难,因为它们的低能X射线很容易被吸收,难以测量。

分析深度

XRF从根本上是一种表面分析技术。穿透深度取决于材料和X射线的能量,但范围可以从几微米到几毫米不等。

如果您正在分析涂层、腐蚀或非均匀的固体,表面测量可能无法反映材料的整体成分。这是一个常见的陷阱,可能导致重大的误解。

高准确度的“成本”

速度和准确性之间存在直接的权衡。手持式XRF可以在几秒钟内提供半定量结果,无需样品制备。要获得高度准确的实验室级结果,可能需要研磨、压制颗粒或制作熔融珠,这需要更多的时间和专业知识。

为您的目标选择正确的方法

根据您需要回答的问题来选择您的方法学。

- 如果您的主要重点是快速分类或材料识别: 干净表面上的最少样品制备通常就足够了,因为您正在寻找主要的成分差异,而不是精确的百分比。

- 如果您的主要重点是过程控制或常规质量保证: 从粉末样品中制作压片,在速度和准确性之间提供了良好的平衡,以监测一致性。

- 如果您的主要重点是认证、研究或地质分析: 严格的样品制备,例如制作熔融珠和使用特定类型的校准标准,对于实现尽可能高的准确性是必不可少的。

最终,您的XRF分析的准确性是您的方法学质量的直接反映。

摘要表:

| 因素 | 对准确度的影响 | 关键考虑因素 |

|---|---|---|

| 样品制备 | 高 | 为分析创建一个均匀的、有代表性的表面。 |

| 校准标准 | 高 | 必须与样品类型(例如,金属、土壤)匹配才能获得可靠的结果。 |

| 基体效应 | 中等 | 其他元素会吸收或增强X射线;需要校正。 |

| 粒径/均匀度 | 中等 | 对粉末至关重要;熔融珠提供最高的准确度。 |

| 检测限 | 固有局限性 | 不适用于超痕量(ppb)或非常轻的元素分析。 |

为您特定的应用实现最高的准确度。 您的XRF分析的精度不仅仅是关于仪器——它关乎整个方法学。KINTEK专注于实验室设备和耗材,服务于实验室需求。我们的专家可以帮助您选择正确的样品制备设备和校准标准,以确保您的XRF结果可靠且可信赖。

立即联系我们的专家讨论您的分析目标并优化您的XRF流程!

图解指南

相关产品

- 实验室筛分机和筛分设备

- 实验室灭菌器 实验室高压灭菌器 脉冲真空升降灭菌器

- 实验室材料与分析金相试样镶嵌机

- HFCVD设备用于拉丝模具纳米金刚石涂层

- 实验室灭菌器 实验室高压蒸汽灭菌器 液体显示自动型立式压力蒸汽灭菌器