为什么选择我们

简易的订购流程、优质的产品和专业的支持,助力您的业务成功。

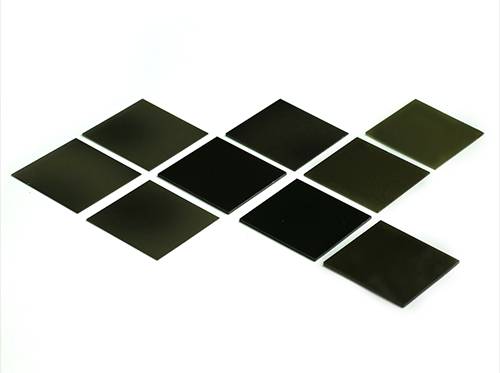

简介

金刚石刀具是一种在刀具工作部分通过粘合剂固定金刚石颗粒的金属切削刀具。金刚石刀具具有许多优点,包括工作效率高、磨削力低、耐磨性高、磨削质量和精度高。

CVD金刚石刀具广泛用于切削有色材料、陶瓷、耐磨复合材料、高硅铝合金、石墨和其他难加工材料。它们具有出色的耐磨性、低摩擦系数、完美的导热性、高断裂强度和韧性,以及更好的尺寸和热稳定性。

应用

CVD金刚石刀具因其优异的性能而被广泛应用于各个工业领域。这些刀具在切削和加工各种材料方面已被证明非常有效,包括:

-

有色材料:CVD金刚石刀具在切削铝、铜及其合金等有色金属方面表现出色。其高导热性和低摩擦系数可确保清洁、精确的切削操作。

-

陶瓷:CVD金刚石的极高硬度和耐磨性使其成为切削陶瓷材料的理想选择。它可以高效加工陶瓷,精度高,切屑或断裂少。

-

耐磨复合材料:CVD金刚石刀具在切削耐磨复合材料方面非常有效,这类材料常用于航空航天和汽车等行业。这些刀具能够承受材料的磨蚀性,从而延长刀具寿命并提高切削性能。

-

高硅铝合金:CVD金刚石刀具非常适合切削高硅铝合金,这类合金以其硬度和磨蚀性而闻名。金刚石卓越的耐磨性使其能够保持锋利度并提供一致的切削效果。

-

石墨:CVD金刚石刀具常用于切削石墨,这是一种需要小心处理的软而脆的材料。金刚石的高导热性可防止切削刃处积聚热量,确保切削干净、精确。

-

其他难加工材料:CVD金刚石刀具在切削玻璃、碳纤维和某些塑料等各种挑战性材料方面也展现了其能力。其多功能性使其成为各种工业应用中的宝贵资产。

特性

CVD金刚石刀具为用户带来一系列优势,包括:

-

出色的耐磨性:这意味着CVD金刚石刀具可以使用更长时间,无需更换,从而减少停机时间并提高生产率。

-

低摩擦系数:这有助于减少加工过程中产生的热量,从而改善表面光洁度和延长刀具寿命。

-

完美的导热性:这使得CVD金刚石刀具可以在较低温度下运行,有助于防止工件和刀具本身损坏。

-

高断裂强度和韧性:这使得CVD金刚石刀具更耐崩边和断裂,即使在重切削载荷下也是如此。

-

更好的尺寸和热稳定性:这有助于确保CVD金刚石刀具随着时间的推移保持其形状和切削性能,从而获得更一致的结果。

-

应用范围广:CVD金刚石刀具可用于切削多种材料,包括有色金属、陶瓷、耐磨复合材料、高硅铝合金、石墨和其他难加工材料。

原理

通过DC电弧等离子体射流制造的刀具毛坯通常比其他技术制造的刀具毛坯具有更高的导热性,即使在相对较高的生长速率下也是如此。这显然有利于重载高速切削操作。极低的摩擦系数、更高的断裂强度和断裂韧性、极高的热氧化抗性,加上更高的导热性,应使其成为高性能切削的理想材料。

优点

-

出色的耐磨性:CVD金刚石刀具的使用寿命可达传统硬质合金刀具的100倍,从而减少了更换刀具的停机时间,提高了生产率。

-

低摩擦系数:这减少了切削过程中产生お热量,有助于防止工件损坏并改善表面光洁度。

-

完美的导热性:CVD金刚石具有非常高的导热性,有助于将热量从切削刃散发出去,防止刀具磨损。

-

高断裂强度和韧性:CVD金刚石是一种非常坚韧的材料,即使在重切削载荷下也能抵抗崩边和断裂。

-

更好的尺寸和热稳定性:CVD金刚石在高温下非常稳定,有助于在恶劣条件下保持其切削性能。

-

取向无关性:CVD金刚石是多晶材料,这意味着它没有优选取向。这使其非常适合用于切削刀具承受多个方向的应用。

行业领军企业信赖之选

FAQ

直流普拉姆萨射流制造的刀具坯料与其他技术制造的刀具坯料有何不同?

什么是 CVD 金刚石设备?

CVD 二芒星切割工具有哪些应用?

CVD 金刚石设备如何工作?

如何解决锻造坯料公差过小的问题?

使用 CVD 金刚石设备有哪些优势?

选择 CVD 金刚石设备时应考虑哪些因素?

CVD 金刚石设备生产的金刚石有哪些常见应用?

4.9 / 5

KINTEK SOLUTION's Cutting Tool Blanks are a game-changer! They are incredibly durable and have significantly improved our productivity.

4.8 / 5

I highly recommend these Cutting Tool Blanks. They offer an exceptional balance of quality and value. The fast delivery is a bonus!

4.7 / 5

KINTEK SOLUTION's Cutting Tool Blanks have exceeded my expectations. The quality is top-notch, and they have significantly reduced our production costs.

4.6 / 5

These Cutting Tool Blanks are a must-have for any laboratory. They are reliable, efficient, and built to last.

4.9 / 5

I was impressed by the cutting-edge technology used in these Cutting Tool Blanks. They have revolutionized our laboratory operations.

4.8 / 5

KINTEK SOLUTION's Cutting Tool Blanks are worth every penny. They have significantly improved the accuracy and precision of our cutting processes.

4.7 / 5

These Cutting Tool Blanks are incredibly user-friendly and have made our laboratory work much easier. I highly recommend them.

4.6 / 5

KINTEK SOLUTION's Cutting Tool Blanks are a valuable addition to our laboratory. They have increased our productivity and efficiency.

4.9 / 5

I am highly satisfied with the durability and performance of these Cutting Tool Blanks. They are an excellent investment.

4.8 / 5

These Cutting Tool Blanks are a testament to KINTEK SOLUTION's commitment to innovation. They have transformed our cutting operations.

4.7 / 5

I highly recommend these Cutting Tool Blanks for their exceptional quality and reliability. They have exceeded our expectations.

4.6 / 5

KINTEK SOLUTION's Cutting Tool Blanks are a great value for the price. They have significantly reduced our downtime and increased our productivity.

4.9 / 5

I am extremely impressed with the speed of delivery and the exceptional customer service I received from KINTEK SOLUTION.

4.8 / 5

These Cutting Tool Blanks are a fantastic investment. They have significantly improved the quality of our cutting operations.

4.7 / 5

KINTEK SOLUTION's Cutting Tool Blanks are a perfect fit for our laboratory. They are precise, efficient, and built to last.

4.6 / 5

I am very satisfied with the performance and durability of these Cutting Tool Blanks. They have made a noticeable difference in our operations.

4.9 / 5

KINTEK SOLUTION's Cutting Tool Blanks are a game-changer for our laboratory. They have increased our efficiency and improved the accuracy of our cutting processes.

4.8 / 5

These Cutting Tool Blanks are a testament to the quality and innovation of KINTEK SOLUTION. They have exceeded our expectations.

4.7 / 5

I highly recommend KINTEK SOLUTION's Cutting Tool Blanks. They are a valuable addition to any laboratory and have significantly improved our operations.

4.6 / 5

These Cutting Tool Blanks are an excellent investment. They have significantly reduced our production costs and improved the quality of our products.

获取报价

我们的专业团队将在一个工作日内回复您。请随时与我们联系!

相关产品

高精度金刚石线切割机 实验室用精密线切割机

高精度金刚石线切割机是一种多功能、高精度的切割工具,专为材料研究人员设计。它采用连续金刚石线切割机制,能够精确切割陶瓷、晶体、玻璃、金属、岩石以及各种脆性材料。

相关文章

用 MPCVD 机器制造 CVD 金刚石的过程

CVD 金刚石设备在各行各业和科学研究中发挥着重要作用。

用于现代加工的金刚石砂轮切割机和对新型切割工具的需求

钻石因其超凡的硬度、卓越的导热性和化学稳定性而广受欢迎。

了解 CVD 金刚石设备及其工作原理

CVD(化学气相沉积)金刚石制造工艺是利用气相化学反应将碳原子沉积到基底上。该工艺首先要选择高质量的金刚石种子,然后将其与富碳混合气体一起放入生长室。

半导体行业如何使用 CVD

化学气相沉积技术为半导体行业带来了革命性的变化,使高性能电子设备的生产成为可能,并增强了设备的功能性和可靠性。

成功实现 CVD 工艺的关键材料

化学气相沉积工艺的成功取决于工艺中所用前驱体的可用性和质量。

用于大尺寸单晶金刚石的 MPCVD 系统的进步

MPCVD 系统的进步使得生产更大、更高质量的单晶金刚石成为可能,为未来的应用提供了广阔的前景。

MPCVD 综合指南》:金刚石合成与应用

探索微波等离子体化学气相沉积 (MPCVD) 在金刚石合成中的基本原理、优势和应用。了解它的独特功能以及与其他金刚石生长方法的比较。

使用 CVD 管式炉进行涂层的优势

CVD coatings have several advantages over other coating methods, such as high purity, density, and uniformity, making them ideal for many applications in various industries.

CVD 涂层如何帮助您实现高纯度和高密度

与其他涂层技术相比,CVD 工艺具有多种优势,如纯度高、均匀性好,并能沉积出高密度的涂层。

比较 CVD 合成钻石和 HPHT 培养钻石:有哪些区别?

CVD 和 HPHT 钻石都被认为是真正的钻石,因为它们由纯碳组成,具有与天然钻石相同的物理和化学特性。

如何检查您的钻石是否是 CVD 生产的

在购买钻石时,了解天然钻石和使用 CVD 技术生产的钻石之间的区别非常重要。

CVD 薄膜技术入门指南

CVD 被广泛应用于各行各业,包括半导体行业,用于生产电子设备的薄膜。