Introduction to Isostatic Pressing

Isostatic pressing is a manufacturing process that is widely used in the production of complex-shaped parts. It involves applying equal pressure from all directions to a material placed inside a flexible mold. This is done to eliminate any voids or porosity in the material, resulting in a denser and stronger final product. Isostatic pressing can be performed using either cold isostatic pressing (CIP) or hot isostatic pressing (HIP), depending on the material's properties and the desired final product. The process has several advantages over traditional manufacturing methods, including the ability to produce complex shapes with high precision and uniform density, making it an attractive option for many industries.

Table of Contents

Advantages of Isostatic Pressing

Isostatic pressing is a manufacturing process that offers several advantages for producing parts with internal shapes. Here are some of the main advantages of isostatic pressing:

1. Uniform and Homogenous Product

One of the main advantages of isostatic pressing is the ability to produce a dense and homogenous product. The process involves applying pressure from all directions, resulting in a uniform distribution of the material throughout the part. This ensures that the product is free from defects and voids, making it ideal for applications where high precision is required.

2. Complex Shapes with High Precision

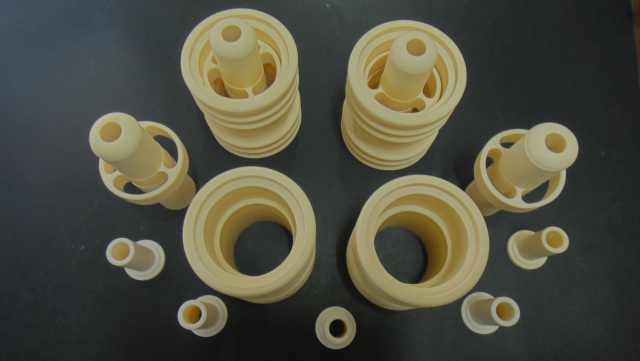

Isostatic pressing is capable of producing parts with intricate internal shapes with high precision. The process ensures that the material is evenly distributed throughout the part, making it possible to create complex shapes that are difficult or impossible to produce using traditional manufacturing techniques. This makes the process an attractive option for a wide range of industries.

3. High Strength and Durability

Isostatic pressing allows for the creation of parts with a uniform microstructure, which enhances their mechanical properties. This results in parts that have a high level of strength and durability. Additionally, the process can be used to create parts with a high degree of purity, which is important in applications where contamination can be detrimental.

4. Reduced Machining and Material Costs

Isostatic pressing can be used to produce near-net-shape parts, reducing the amount of machining required. This can result in significant cost savings, as less material is required for the production of the part. Additionally, isostatic pressing allows for the enhancement of alloying elements without inducing segregation in the material, making it possible to use premium or expensive materials in critical regions only.

5. Reduction in Lead Times

Isostatic pressing allows for the production of complex shapes in prototype and production quantities with significantly reduced lead times compared to other manufacturing methods. This is because the process makes it possible to economically produce the parts without the need for extensive machining.

6. Large Range of Component Sizes

Isostatic pressing is capable of producing parts with a wide range of sizes, from massive 30-ton near net PM shapes down to densifying less than 100-gram MIM parts. Additionally, the size of the pressed parts is limited only by the size of the isostatic pressure chamber.

In conclusion, isostatic pressing is an effective and efficient manufacturing process that offers several advantages over traditional manufacturing techniques. Its ability to produce parts with complex internal shapes, high precision, and consistent quality make it an attractive option for a wide range of industries.

Powder Preparation for Isostatic Pressing

The process of isostatic pressing involves compressing a powder into a desired shape using equal pressure from all directions. Powder preparation is a crucial step in this process as the quality of the final product heavily relies on the quality of the powder. The following are the steps involved in powder preparation for isostatic pressing:

Powder Selection

The powder must be carefully selected to ensure that it has the desired particle size, shape, and distribution. The size and shape of the powder particles can greatly affect the final product's mechanical and physical properties. The powder must also be free from impurities and contaminants.

Powder Mixing

The powder is typically mixed with a binder to enhance its strength and formability. The composition of the powder and binder mixture is carefully controlled to ensure that the final product has the desired mechanical and physical properties. The powder mixture is then compacted into a preform using a uniaxial press.

Preform Formation

The preform is then placed into a flexible mold. The mold must be carefully designed to ensure that the preform is uniformly compressed into the desired shape, with no air pockets or defects. The preform is then subjected to high-pressure isostatic pressing.

High-Pressure Isostatic Pressing

This process ensures that the powder is uniformly compressed into the desired shape, with no air pockets or defects. The high-pressure is applied uniformly from all directions, ensuring that the powder is compressed evenly. The pressure is typically applied using a liquid or gas medium that surrounds the powder.

Advantages of Proper Powder Preparation

Proper powder preparation is critical in ensuring the quality of the final product. The process offers several advantages, including the ability to produce complex shapes with high precision and consistency, high strength and density, and the ability to work with a variety of materials including ceramics, metals, and composites. It also removes many of the constraints that limit the geometry of parts compacted unidirectionally in rigid dies. It is applicable to difficult-to-compact and expensive materials such as superalloys, titanium, tool steels, stainless steel, and beryllium, with material utilization that is highly efficient.

In conclusion, powder preparation is a critical step in isostatic pressing, and it must be carefully controlled to produce high-quality parts with complex internal shapes. The proper selection, mixing, and preform formation of the powder are the key steps in ensuring the quality of the final product. Isostatic pressing is widely used in various industries, including aerospace, automotive, and medical industries, due to its ability to produce complex shapes with high precision and consistency.

Cold Isostatic Pressing (CIP)

Cold Isostatic Pressing (CIP) is a manufacturing process used for producing parts with complex internal shapes. It is a form of isostatic pressing that involves applying high pressure to a powder-filled container using a fluid medium. The fluid evenly distributes the pressure throughout the container, resulting in a uniform pressure on the powder. This pressure compacts the powder, creating a solid part with a complex internal shape.

How CIP Works

In the cold isostatic pressing process, a mould or vacuumed sample is placed into a chamber that is filled with a working fluid, usually water with a corrosion inhibitor, which is pressurized by an external pump. The pressure chamber is designed to withstand the severe cyclic loading imposed by rapid production rates and has taken into account fatigue failure. Compared with cold pressing, isostatic compaction applies pressure uniformly over the entire surface of the mould. Die-wall friction, which exerts a major influence on the density distribution of cold-pressed parts, is absent; so much more uniform densities are obtained.

Benefits of CIP

CIP offers several advantages over traditional manufacturing methods, including the ability to produce parts with high density, uniformity, and strength. Additionally, CIP can produce parts with complex shapes that would be difficult or impossible to create using other methods. The process is also cost-effective and environmentally friendly, as it generates less waste than other manufacturing processes.

Applications of CIP

CIP is commonly used in the production of ceramic and metal parts, such as turbine blades, heat exchangers, and engine components. The process is also used to produce parts for the medical and aerospace industries. With typical pressures from 1,035 to 4,138 bar (15,000 to 60,000 psi) and ambient temperature up to 93°C (200°F), CIP can achieve 95% of theoretical density for ceramics. Common applications for CIP include consolidation of ceramic powders, compressing of graphite, refractories and electrical insulators, and other fine ceramics for dental and medical applications.

Electrical CIP

Compared with manual CIP, electrical CIP can deliver better pressure control. This is a method of compacting powdered materials into a solid homogeneous mass before machining or sintering. It is commonly used for parts that are too large to be pressed in uniaxial presses and that do not require high precision in the sintered state.

In conclusion, Cold Isostatic Pressing (CIP) is an important tool in the manufacturing industry, enabling the production of high-quality parts with complex internal shapes. Its benefits make it a popular choice for companies looking to create high-performance components for a wide range of applications.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a unique method of isostatic pressing used for producing parts with internal shapes and achieving uniform densities in a material. HIP involves heating a material and applying pressure to it simultaneously. The process is commonly used in the manufacturing of high-performance components used in the aerospace and medical industries.

How Does HIP Work?

The process involves placing the material in a sealed container, which is then filled with gas and heated to high temperatures. The pressure applied during the heating process ensures that the material is evenly compressed, resulting in increased density and strength. The surfaces of the voids diffusion bond together to effectively eliminate the defects achieving near theoretical density, while improving mechanical properties of the parts such as investment castings. The temperature, pressure, and process time are all precisely controlled to achieve the optimum material properties.

Benefits of HIP

HIP is particularly useful in producing parts with intricate internal geometries, such as turbine blades and dental implants. HIP also eliminates any porosity or voids in the material, resulting in a more uniform and reliable final product. As a result of its effectiveness, HIP has become increasingly popular in the manufacturing industry as a way to produce high-quality, complex components.

Applications of HIP

HIP is a well-established process for the improvement of a wide variety of materials such as titanium, steel, aluminum, and superalloys. Using this process, voids within a casting can be reduced or eliminated and encapsulated powders can be consolidated to create fully dense materials. Also, similar and dissimilar materials can be bonded together to manufacture unique and cost-effective components.

Advantages of HIP

When incorporated as an integral part of the manufacturing process, HIP reduces scrap and improves yield. It frequently allows the replacement of wrought components by castings, and reduces quality assurance inspection requirements by improving material properties and reducing property scatter. HIP can optimize material properties, and parameters can be established to minimize subsequent heat treatment requirements. Processed parts exhibit enhanced reliability and extension of service life. HIP allows for smaller, lighter-weight parts with similar or superior performance, and can reduce the total production costs of a product.

In conclusion, HIP is a highly effective process for producing high-quality, complex components with intricate internal geometries. It is useful in a variety of industries, including aerospace and medical, and offers many benefits over traditional manufacturing processes.

Main Benefits of Isostatic Pressing

Isostatic pressing is a versatile manufacturing process that offers several benefits over traditional pressing methods. Here are the main benefits of isostatic pressing:

Ability to Produce Complex Geometries

Isostatic pressing allows for the production of parts with complex geometries, including internal shapes, with high accuracy and consistency. The process applies pressure uniformly to the powder, which creates a dense and uniform part. This is particularly useful in applications where dimensional accuracy is critical.

Production of Parts with High Degree of Uniformity

Isostatic pressing allows for the production of parts with a high degree of uniformity. This is important in applications where consistent quality and performance are required. The process helps to improve the structural integrity and durability of the part.

Range of Materials

Isostatic pressing can be used to produce parts with a range of materials, including metals, ceramics, and composites. This makes it a versatile manufacturing process that can be used in various applications.

Production of Parts for High-Temperature or High-Pressure Applications

Isostatic pressing is particularly useful in the production of parts that are used in high-temperature or high-pressure applications. The process helps to improve the structural integrity and durability of the part, making it more reliable in extreme working conditions.

Reduction of Defects

Isostatic pressing helps to reduce defects such as pores, cracks, and segregation that remain in the production of cast products. These defects greatly reduce material performance, service life, and stability. The process helps to improve the mechanical properties and workability of additive manufacturing materials.

In conclusion, isostatic pressing is a versatile and effective manufacturing process that offers several benefits over traditional pressing methods. The ability to produce complex geometries, high degree of uniformity, range of materials, production of parts for high-temperature or high-pressure applications, and reduction of defects are some of the main benefits of isostatic pressing.

Conclusion

In conclusion, Isostatic Pressing is a highly effective manufacturing process for producing parts with complex shapes and internal features. The process involves powder preparation, cold or hot isostatic pressing, and sintering. Isostatically pressed parts have improved mechanical properties, uniform density, and are resistant to cracks and deformations. While the process may be costly, the benefits of producing high-quality parts with complex geometries make it a worthwhile investment. Isostatic pressing is commonly used in aerospace, medical, and automotive industries.