批次式炉的运行温度完全由其特定应用决定,范围从用于简单回火的几百度到用于先进材料合成的 3000°C 以上。例如,用于石墨化的专用批次炉必须在极高温度下运行,通常在 2500°C 至 3000°C (4532°F 至 5432°F) 之间,以在原子水平上重构碳。

批次炉没有单一的运行温度。相反,其温度范围是根据所处理的材料和所需进行的物理或化学转变(从简单的金属退火到超高温石墨化)而决定的关键设计规范。

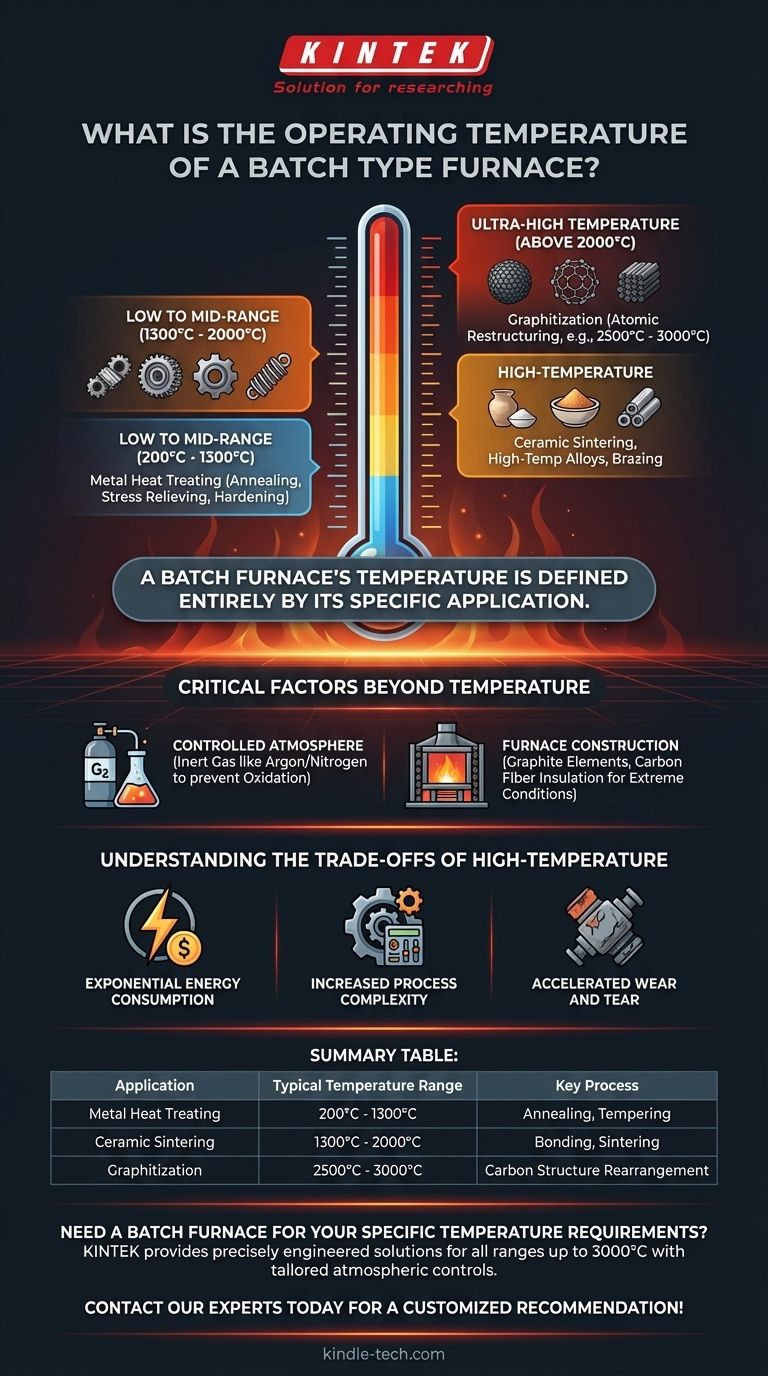

温度在材料转变中的作用

炉子的目的是利用热能来改变材料的性能。因此,所需的温度与特定的转变需求直接相关。

低温至中温工艺 (200°C - 1300°C)

许多常见的金属(如钢和铝)热处理工艺都在此范围内进行。这些温度足以改变晶体结构,以达到 软化(退火)、消除应力或硬化 等目的。

高温工艺 (1300°C - 2000°C)

此范围常用于烧结陶瓷、加工高温合金和某些类型的钎焊。需要更高的能量输入才能将颗粒粘合在一起或实现材料结构上更显著的变化。

超高温工艺 (高于 2000°C)

石墨化等工艺需要极高的温度。在 2500°C 至 3000°C 时,强烈的热能迫使含碳材料中无序的原子重新排列成高度有序的石墨层状结构。

温度之外的关键因素

达到目标温度只是等式的一部分。对于像石墨化这样的工艺要成功,其他环境因素同样关键。

受控气氛

在接近 3000°C 的温度下,材料与氧气会发生高度反应。在环境空气中操作会导致碳材料直接燃烧殆尽(氧化)。

为防止这种情况,这些炉子会充满 受控的惰性气氛,通常使用氩气或氮气。这种非反应性环境可以保护材料免受氧化和其他不需要的化学反应,确保最终产品的完整性。

炉体结构

能够达到 3000°C 的炉子与标准热处理炉在结构上有着根本的不同。其结构需要能够承受如此极端条件的特种材料。

加热元件通常由石墨制成,绝缘材料由碳纤维复合材料组成,因为传统的金属合金和陶瓷纤维在这些温度下会灾难性失效。

理解高温操作的权衡

将炉子推到如此极端的温度会带来重大的挑战和成本,这些必须通过工艺结果来证明其合理性。

指数级的能耗

增加和维持炉温所需的能量呈指数级增长。为 3000°C 炉子供电所需的成本和基础设施比 1200°C 炉子高出好几个数量级。

增加的工艺复杂性

管理惰性气氛、确保精确的温度均匀性以及在这些高温下处理材料,需要复杂的控制系统和受过高度培训的操作员。工艺失败的风险也明显更高。

加速的磨损

即使使用特种材料,超高温炉内部的部件也会更快地降解。这会导致更高的维护成本、更频繁的停机时间和设备的整体寿命缩短。

为您的目标做出正确的选择

正确的炉子是能够满足您的工艺要求而又不过度具备能力的那个。选择正确的温度范围是最基本的一步。

- 如果您的主要重点是标准的金属热处理(例如退火、回火): 运行温度高达 1300°C 的炉子绰绰有余,而且成本效益更高。

- 如果您的主要重点是烧结先进陶瓷或加工难熔金属: 您将需要一台能够达到 1600°C 至 2000°C 的高温炉。

- 如果您的主要重点是石墨化或生产先进碳材料: 您需要一台专用的、超高温批次炉,设计用于在精确的大气控制下在 2200°C 以上运行。

最终,您必须将炉子的温度能力与您的工艺所需的特定材料转变相匹配。

摘要表:

| 应用 | 典型温度范围 | 关键工艺 |

|---|---|---|

| 金属热处理 | 200°C - 1300°C | 退火、回火 |

| 陶瓷烧结 | 1300°C - 2000°C | 粘合、烧结 |

| 石墨化 | 2500°C - 3000°C | 碳结构重排 |

需要满足您特定温度要求的批次炉?

无论您的实验室工艺需要标准的金属热处理还是高达 3000°C 的超高温石墨化,KINTEK 都能提供精确设计的批次炉,具备您的应用所需的精确温度范围和气氛控制。我们在实验室设备方面的专业知识可确保您获得满足材料转变目标的可靠、高效的解决方案。

立即联系我们的专家 讨论您的具体需求并获得定制化的建议!

图解指南