目录

XRF 分析和样品制备简介

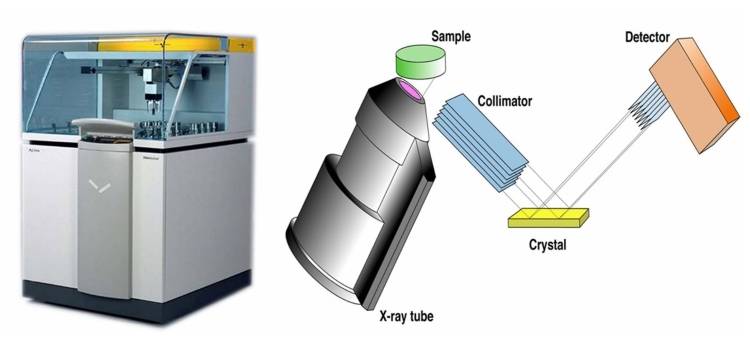

X 射线荧光 (XRF) 分析是材料表征的关键技术,可提供无损且高度准确的结果。然而,这些结果的质量在很大程度上取决于样品的精心制备。本文深入探讨了 XRF 样品制备的复杂性,强调了确保均匀性、设计有效配方、选择适当设备、维护安全协议、开发一致的工作流程以及通过培训和合规性提高技能的重要性。通过掌握这 7 项行之有效的 PRESS 策略,您可以获得最佳结果,并将 XRF 分析的精度和可靠性提升到新的高度。

P - 准备:确保样品均匀

为 X 射线荧光 (XRF) 分析准备样品是一个关键步骤,直接影响分析结果的准确性和可靠性。我们的目标是制作出均匀的样品,无论材料类型或形态如何,都能进行一致的分析。本节将深入探讨如何准备 XRF 分析样品的详细步骤,尤其是均质化技术和高质量 XRF 粒模的使用。

均质技术

均质化是使样品成分均匀的过程,这对精确的 XRF 分析至关重要。以下是实现样品均匀的常用技术:

-

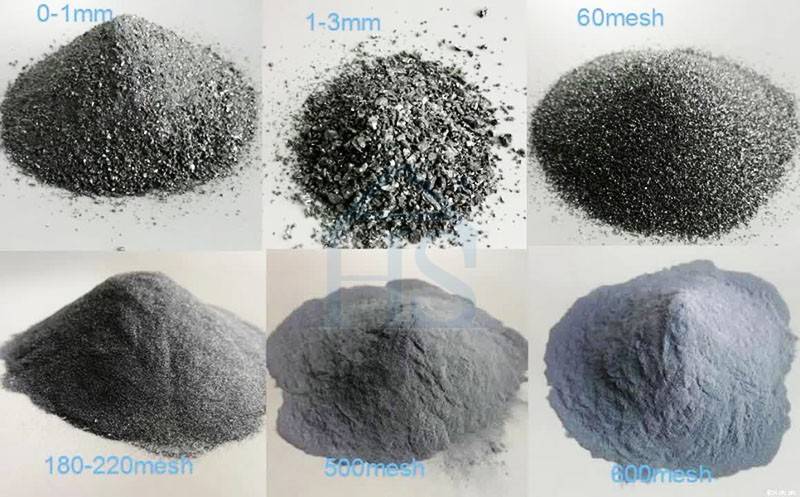

研磨:均匀化的第一步是将样品研磨成细粉。理想情况下,粒度应小于 75 微米(<75μm)。这样可以确保样品分布均匀,减少可能导致读数不准确的空隙。对于大多数材料来说,研磨到这种细度就足以获得均匀的样品。

-

混合:研磨后,应彻底混合样品。可以使用机械搅拌机或手动搅拌粉末。这样做的目的是确保样品的所有部分都具有相同的代表性,这对 XRF 分析的一致性至关重要。

-

装订:在某些情况下,可以在粉末样品中添加结合剂。这对于难以压制成颗粒的样品尤其有用。常见的粘合剂包括纤维素蜡混合物,其添加比例通常为样品粘合剂的 20%-30%。粘合剂有助于将样品固定在一起,确保颗粒均匀。

使用高质量的 XRF 颗粒模具

样品均匀化后,下一步就是使用高质量的 XRF 颗粒模具将其压制成颗粒。与松散的粉末相比,压制颗粒是一种更严格的样品制备方法,因为它们能为分析提供更均匀、更稳定的表面。以下是需要遵循的步骤:

-

装模:在将样品装入模具之前,确保样品没有任何结块,并且完全均匀。这对形成一致的颗粒至关重要。

-

压制:使用液压机对样品施加压力。建议的压力范围为 20-30 吨(20-30T)。此压力足以产生致密、均匀的颗粒,而不会导致样品过热或变形。

-

润滑:在模具上涂抹颗粒压制润滑剂,以防止样品粘连。这样可以确保颗粒可以很容易地从模具中取出,而不会对其造成损坏。

-

重复:对每个需要压制成 XRF 颗粒的样品都要重复此过程。压制过程的一致性是获得可靠结果的关键。

成功压制 XRF 颗粒的技巧

-

质量模具:始终使用高质量的 XRF 颗粒模具,以确保颗粒形状和尺寸的一致性。劣质模具会导致颗粒不规则,从而影响分析的准确性。

-

个人防护设备 (PPE):在处理粉末样品时,请务必佩戴适当的个人防护设备,如手套和安全眼镜。这可以保护您免受处理细粉末时的潜在危险。

-

制造商说明:遵守液压机制造商的说明,确保正确使用。这包括设置适当的压力和确保压力机正常工作。

-

校准标准:您选择的样品制备方法应适用于校准标准和任何未知样品。这可确保校准的准确性和一致性。

R - 配方设计:成功压制颗粒的关键因素

设计颗粒压制的样品制备配方是确保分析结果准确性和可重复性的关键步骤。这一过程涉及几个必须严格控制的关键因素。这些因素包括粒度、粘合剂的选择、样品稀释比例、压制压力和颗粒厚度。这些因素中的每一个都对最终颗粒的质量和一致性起着至关重要的作用,从而直接影响到分析数据的可靠性。

粒度

样品的粒度是制备颗粒的最关键因素之一。粒度越小,结合力越强,颗粒越均匀。理想情况下,样品的研磨粒度应小于 50µm。不过,粒度最大可达 75 微米的颗粒也能产生可接受的结果。使用较小颗粒的理由是,它们能为粘合剂提供更多的附着表面积,从而使颗粒更结实、更有内聚力。另一方面,较大的颗粒可能会导致较弱的颗粒,在处理或分析过程中可能会破裂,从而损坏光谱仪并影响样品。

粘合剂的选择

粘合剂的选择是颗粒制备过程中的另一个关键因素。粘合剂的作用是在压力下将样品颗粒固定在一起,确保颗粒在分析过程中保持完整。颗粒压制过程中最常用的粘合剂是蜡、纤维素或聚乙烯醇(PVA)等有机材料。粘合剂的选择取决于样品类型和所使用的分析技术。例如,蜡粘合剂通常是 X 射线荧光 (XRF) 分析的首选,因为它们能够承受高压并提供良好的颗粒完整性。

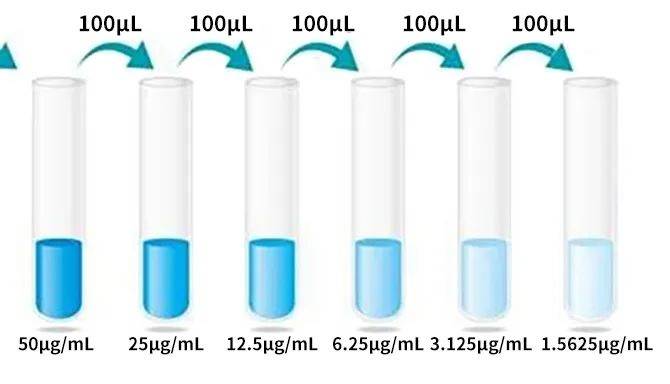

样品稀释比

样品稀释比是指粘合剂与样品的比例,也是一个关键参数。通常的做法是使用 20-30% 的粘合剂与样品比例。这一比例可确保样品得到充分粘合,而不会被过度稀释。稀释过度会导致颗粒脆弱,容易破碎,而稀释不足则会导致颗粒过于致密,难以处理。粘合剂与样品比例的一致性对重现性至关重要,因为任何变化都会导致分析结果出现误差。

压力

压制压力是指施加到样品与粘合剂混合物上以形成颗粒的力。所需的压力因所使用的样品和粘合剂类型而异。一般来说,压力越大,颗粒越致密、越耐用。但是,过大的压力会导致颗粒开裂或变形,从而导致结果不一致。在方法开发过程中,为每种样品类型确定一个最佳压力范围非常重要。应始终保持这一范围,以确保颗粒的质量和重现性。

颗粒厚度

最终颗粒的厚度是另一个必须仔细控制的因素。颗粒的厚度会影响样品的均匀性和分析结果的准确性。较厚的颗粒可能会导致压缩不均匀,从而导致分析信号的变化。相反,过薄的颗粒可能过于脆弱,容易破碎。理想的颗粒厚度通常在 1-3 毫米之间,具体取决于所用分析技术的具体要求。保持一致的颗粒厚度对于确保结果的可重复性至关重要。

实际考虑因素

在实践中,压制颗粒的制备涉及多个步骤,包括将样品研磨到适当的粒度、将样品与粘合剂混合、将混合物转移到颗粒压制模具中,以及施加必要的压力以形成颗粒。每个步骤都必须精确一致,以确保最终颗粒的质量。注意细节,如将样品混合物均匀地撒在压模中和施加正确的压力,对于最大限度地减少误差和获得可靠的分析结果至关重要。

E - 设备:为工作选择正确的工具

说到 XRF 压制颗粒,选择正确的设备对于确保结果的准确性和一致性至关重要。该过程包括从粉末样品中制造均匀的固体颗粒,然后使用 X 射线荧光 (XRF) 光谱进行分析。本节将引导您了解选择最佳设备的主要考虑因素,尤其是使用 KINTEK 自动液压机和其他基本工具的好处。

手动与自动液压机

手动液压机和自动液压机之间的选择主要取决于 XRF 分析的数量和频率。手动液压机虽然具有成本效益,但需要操作人员付出大量体力,尤其是在施加高压时。这些压力机的最大压力通常可达 250 kN,压力显示清晰,通过手柄操作简单。不过,实现高压所需的体力可能会很吃力,并可能导致压力应用不一致。

另一方面,自动液压机具有多种优势,特别是在繁忙的实验室中。这些压力机一旦设置好,就可以通过编程自动运行,这样技术人员就可以专注于其他任务。自动压力机有多种配置,如 30 吨、40 吨和 60 吨,操作起来也更省力。由于消除了使用过程中的可变因素,自动压力机具有更高的精度和一致性,因此非常适合频繁的压制工作。

KINTEK 自动液压机的优点

KINTEK 是知名的高质量实验室设备制造商,包括专为 XRF 颗粒制备设计的自动液压机。这些压机专为满足高通量实验室的需求而设计,具有以下几个主要优点:

-

高通量:KINTEK 自动液压机设计用于快速高效的操作,可快速制备多个样品。这对处理大量 XRF 分析的实验室尤其有利。

-

集成式颗粒模具:这些压制机配备了集成的颗粒模具,可简化流程并减少每个样品的制备时间。压模的设计可确保均匀的颗粒形成,这对精确的 XRF 分析至关重要。

-

自动化:KINTEK 压机的自动化功能可实现一致且可重复的结果。一旦编程,压片机就能自动运行,减少人为错误的风险,确保每个样品都按照相同的严格标准制备。

-

易于使用:KINTEK 压片机设计有用户友好界面,即使是专业技术水平有限的人员也能轻松操作。压机还配有自动泄压系统,可防止压力过大,确保安全。

-

多功能性:KINTEK 自动液压机可兼容各种类型的样品,包括可能需要额外粘合剂(如蜡)的样品。这种多功能性确保压片机能够处理各种材料,使其成为任何 XRF 实验室的多功能工具。

XRF 粒子制备的基本工具

除了液压机外,还有其他几种工具也是成功制备 XRF 图谱的必备工具:

-

XRF 微粒模具:这些模具专为从粉末样品中制备均匀的颗粒而设计。它们有各种直径,如 40 毫米、32 毫米和 15 毫米,可灵活调整样品尺寸。

-

颗粒压制润滑剂:在模具和样品上涂一薄层润滑剂可以防止粘连,确保顺利成丸。润滑剂有多种配方,适合不同类型的样品。

-

粉末样品:粉末样品的质量对于精确的 XRF 分析至关重要。样品应研磨成均匀的细粉末,不应有任何结块或杂质。

-

蜡粘合剂:在某些情况下,特别是对于结合力差或不易碎裂的材料,在研磨阶段加入蜡粘合剂可以改善颗粒的形成。蜡粘合剂有粉末状和片剂状两种,使用时应尽量少用,以保证样品的安全粘合。

S - 安全:样品制备过程中的自我保护

在处理粉末样品和使用 XRF(X 射线荧光)设备时,应首先考虑安全问题。个人防护设备 (PPE) 和遵守安全规程的重要性怎么强调都不为过。本节将深入探讨安全的关键方面,以确保操作人员的健康和测量的准确性。

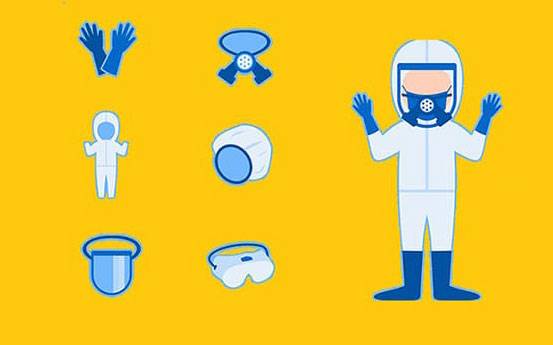

个人防护设备 (PPE)

个人防护设备对于保护操作人员免受与粉末样品和 XRF 设备相关的潜在危害至关重要。个人防护设备的主要组成部分包括

- 手套:处理粉末样品时一定要戴手套,以防止皮肤接触潜在的危险材料。通常建议使用一次性丁腈手套,因为它们对化学品和粉末具有耐受性。

- 安全眼镜或护目镜:保护眼睛免受空气中的微粒和潜在飞溅物的伤害。带侧罩的安全眼镜可提供全面的保护。

- 实验室外套或围裙:穿上实验服或围裙,以保护衣物免受污染。确保外套由易于清洗或一次性的材料制成。

- 呼吸防护:根据粉末的性质,可能需要使用呼吸器来防止吸入有害微粒。请使用经 NIOSH 等监管机构批准的呼吸器。

处理粉末样品的安全规程

正确处理粉末样品对于防止污染和确保准确测量至关重要。以下是一些需要遵守的主要规程:

- 表面清洁:如果对样品的表面清洁度有任何怀疑,请比较研磨前后的测量结果。如果结果相差很大,则再次研磨样品,直到研磨前后的结果相差在测量误差范围内。

- 样品制备:制备粉末样品有多种方法,如粉末压实、助熔剂熔化或直接测量细磨粉末。最简单、最常用的方法是直接测量磨细的粉末。在这种情况下,需要准备测量用的比色皿和薄膜。请咨询供应商,为特定任务和设备选择最合适的薄膜类型。

- 样品均匀性:汽车催化剂或土壤等散装样品在测量前应仔细粉碎。较大的颗粒在成分上会有很大差异,因此粉碎可确保样品更加均匀。如果无法进行粉碎,则可将样品混入比色皿中,取多次测量结果的平均值。

使用 XRF 设备的安全规程

XRF 设备使用 X 射线,如果处理不当,可能对健康有害。以下是操作 XRF 分析仪时应遵守的一些安全规程:

-

辐射安全:XRF 分析仪会发射 X 射线,如果处理不当,会对人体造成伤害。请始终遵守辐射安全规则:

- 远离他人:使用 XRF 分析仪时与他人保持至少 15 英尺(4.57 米)的距离。

- 使用附件:使用测试台等可选附件,尽量减少直接暴露于 X 射线束。

- 培训:为操作员提供辐射安全培训,确保他们了解风险以及如何降低风险。

- 避免直接照射:在分析过程中切勿拿着样品。注意主光束指示器,确保光束不直接照射任何人。

- 小心操作:小心操作和使用 XRF 设备。按照当地的存放要求安全存放。

-

保护盒:保护盒对于保护检测器不受灰尘和污染物的影响至关重要。请定期更换保护盒,因为以前测量过的样品中的灰尘和颗粒会积聚在保护盒上,导致测量结果失真。更换频率可能因测量样品的类型而异。例如,铝合金会留下颗粒,影响后续测量的准确性,因此需要更频繁地更换滤芯。

-

测量时间:确保足够的测量时间以获得准确的结果。测量时间会影响测量的准确性;时间越长,确定样品中元素浓度的误差就越小。通常情况下,需要 10-30 秒才能获得准确的定量结果。

S - 策略:制定一致的制备工作流程

创建 XRF 样品制备的标准化工作流程对于确保结果的一致性和可重复性至关重要。正确的样品制备是准确 X 射线荧光 (XRF) 分析的基础,因为它对分析数据的质量有重大影响。与其他分析技术不同,XRF 不需要大量的样品制备,因此是一种经济高效的方法。不过,这并没有降低建立健全的制备协议的重要性。

固体样品

固体样品,从未经制备的金属片到切割和抛光的金属样品,都需要小心处理,以确保获得准确的结果。用于 XRF 分析的理想样品应具有完全平整的表面。不规则的表面会改变样品与 X 射线源之间的距离,从而带来测量误差。所有 XRF 系统都根据固定的样品到源的距离进行校准,因此任何偏差都会影响 X 射线信号的强度。

对于金属合金和其他固体样品,进行最少量的制备就足以进行定性分析。但是,为了获得更多的定量结果,建议对样品进行切割和抛光。表面抛光对于较轻的元素尤为重要,因为粗糙的表面会导致较长波长元素的散射和再吸收。这种影响与能量有关,也就是说,虽然镍(Ni)等较重的元素可能不会受到明显影响,但碳(C)或硫(S)等较轻的元素可能会显示信号强度的急剧下降。因此,通过车削或研磨实现更精细的表面光洁度对于准确分析至关重要。

粉末样品

制备用于 XRF 分析的粉末样品涉及多种方法,包括粉末压实、助熔剂熔化和直接测量细磨粉末。最简单、最常用的方法是直接测量细磨粉末。这一过程包括选择合适的比色皿和薄膜进行测量。用于 XRF 的薄膜有多种类型,选择合适的薄膜取决于具体任务和使用的设备。咨询供应商对于确保选择最合适的薄膜至关重要。

工作流程一致性

要保持 XRF 分析的一致性,必须建立标准化的工作流程。这包括

-

表面清洁度:分析前,确保样品表面清洁。如果对表面清洁度有任何怀疑,请比较研磨样品前后的测量结果。如果结果差别很大,则再次研磨样品,直到研磨前后的结果差别在测量误差范围之内。

-

微调和校准:定期评估 XRF 设备是否需要微调或校准。这可确保设备以最佳状态运行并提供准确的结果。

-

优化测试时间:调整相关元素的测试时间,确保采集到足够的数据,而不会不必要地延长分析时间。

-

选择正确的模式:根据样品类型和分析元素选择 XRF 分析仪中的适当模式。这会极大地影响结果的准确性。

-

了解样品特征:注意异质性、水分、粒度和不同样品容器对结果的影响。这些因素都会带来可变性,必须加以控制以确保重现性。

-

制定标准操作程序 (SOP):建立 "适合目的 "的方法,并制定样品制备的 SOP。这可确保所有操作人员遵循相同的操作规程,从而获得一致的结果。

-

质量控制与保证 (QC/QA):实施适当的 QC/QA 措施,包括使用基质匹配的有证标准物质 (CRM)、空白样、重复样和副本。这有助于验证结果的准确性和可靠性。

T - 培训与合规性:提高您的 XRF 技能

培训和合规性在掌握 XRF 分析中的作用怎么强调都不为过。适当的培训可确保操作人员了解 X 射线荧光 (XRF) 技术的复杂性,而遵守当地法规则可确保安全、准确地使用设备。本节将深入探讨培训的重要性、遵守当地法规的必要性以及合格人员培训的益处。

培训的重要性

培训是熟练使用 XRF 分析的基石。操作人员必须精通 XRF 技术的理论知识,包括其原理、操作和潜在隐患。如果没有足够的培训,即使是最先进的 XRF 分析仪也会因为校准、样品制备或测量技术不当而导致结果不准确。

例如,初学者最常犯的错误之一就是样品制备不当。金属和合金等固体样品必须彻底清洁,不同的材料通常需要不同的锉刀,以防止交叉污染。土壤或汽车催化剂等散装样品需要粉碎或混合,以确保均匀性。适当的培训可确保操作人员了解这些细微差别,从而获得更可靠、更准确的结果。

另一个关键方面是校准。XRF 分析仪使用基本参数法,需要针对特定任务进行预先校准。误用为合金校准的分析仪来分析贵金属或土壤,可能会导致准确度不高。通过培训,操作员可以掌握为每项任务选择正确校准的知识,从而确保获得定量而非定性的结果。

遵守当地法规

遵守当地法规同样重要。XRF 分析仪使用的是 X 射线,虽然强度较低,但长期暴露在射线下会对健康造成危害。各国和各州的法规各不相同,涉及允许的暴露极限、安全协议和设备标准等方面。遵守这些规定不仅能确保操作人员的安全,还能保证所生成数据的可靠性。

例如,某些法规可能会要求操作员佩戴防护装备或限制连续接触的时间。其他法规可能要求定期检查和维护设备。了解并遵守这些法规对于维持安全的工作环境和确保 XRF 分析仪在法定参数范围内运行至关重要。

结论:实现卓越的 XRF 分析

掌握 XRF 样品制备是获得准确可靠的分析结果的关键一步。通过实施 7 PRESS 策略(制备、配方设计、设备选择、安全协议、策略制定以及培训和合规性),您可以显著提高 XRF 分析的质量和一致性。这些策略不仅能确保最佳的样品制备,还能保护分析人员并保持符合行业标准。通过对这些技术的扎实理解和应用,您可以实现卓越的 XRF 分析,从而在研究和测试过程中获得更精确、更可靠的结果。

相关产品

- FTIR的XRF & KBR塑料环实验室粉末颗粒压片模具

- XRF & KBR 压片机自动实验室液压机

- XRF & KBR 钢环实验室粉末压片模具,用于 FTIR

- XRF硼酸实验室粉末颗粒压片模具

- 实验室液压压片机,适用于XRF KBR FTIR实验室应用