在高温应用中,石墨是一种极端材料。它提供无与伦比的热性能,能够在高达3000°C的温度下运行,而大多数金属在此温度下会失效。其主要优点是卓越的能源效率、低重量以及快速的加热和冷却循环。然而,其主要缺点是颗粒脱落和蒸汽吸收带来的显著污染风险。

石墨的核心权衡是明确的:它在极端环境中提供卓越的热效率和稳定性,但这种性能是以潜在污染为代价的,在敏感过程中必须仔细管理。

石墨在严苛环境中的核心优势

石墨独特的原子结构赋予了它一系列特性,使其在特定的高应力应用中(尤其是涉及强热的应用)具有不可估量的价值。

卓越的热稳定性

石墨最受称赞的品质是其在极端温度下工作的能力。它在高达 3000°C (5432°F) 的条件下仍能保持其结构完整性和性能,远远超过大多数金属和许多陶瓷的操作极限。

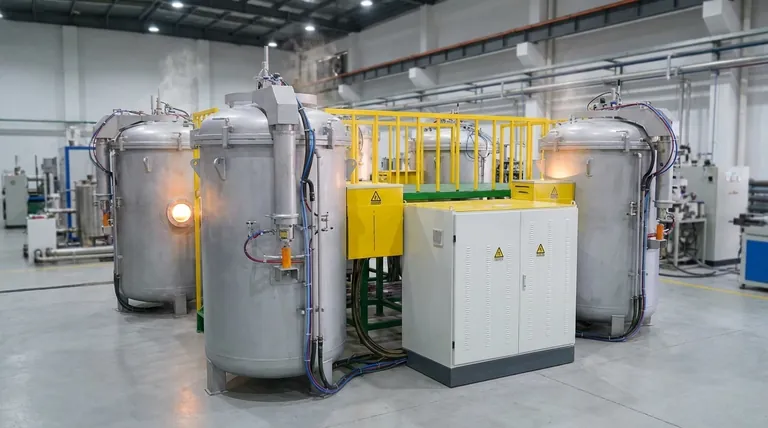

这使其成为高温真空炉、冶炼和铸造等应用中必不可少的材料。

卓越的能源效率

虽然石墨可以吸收大量热量,但其整体能量平衡却非常高效。它具有高发射率,这意味着它能非常有效且均匀地辐射热能。

这导致更短的加热和冷却时间,从而缩短了整体工艺周期,并降低了感应炉等设备的能源需求。

低密度和轻量化

与可能用于相似温度范围的耐火金属相比,石墨的密度要低得多。

这使得组件更轻、更易于处理,并减少了大型炉结构所需的结构支撑质量。它还简化了现场维修和更换。

了解权衡:石墨的主要缺点

使石墨有用的特性也带来了重大挑战。其多孔的层状结构是其最关键缺点的根源。

固有的污染风险

石墨的主要弱点是它倾向于污染其操作环境。这主要通过两种方式发生:颗粒脱落和放气。

这一个问题通常是决定在纯度至上的应用中是否使用石墨的决定性因素。

颗粒脱落

石墨相对较软,会从其表面释放微小颗粒,尤其是当它是低等级或粘合形式时。

在洁净室环境、半导体制造或医疗应用中,这些自由漂浮的碳颗粒可能导致灾难性的产品故障或污染。

蒸汽吸收和放气

石墨是多孔的,会从大气中吸收水分、清洁剂和其他蒸汽。当加热时,尤其是在真空中,它会通过放气过程释放这些被困分子。

这种放气会破坏炉内的真空度,或将不需要的化学杂质引入敏感过程,从而损害最终产品的完整性。

为您的应用做出正确选择

选择石墨需要平衡其无与伦比的热性能与控制污染的关键需求。您的主要目标将决定它是否是正确的选择。

- 如果您的主要关注点是最大热性能和能源效率:石墨是一个极好的,通常是必要的选择,适用于在2000°C以上运行,并且可以容忍或管理少量碳颗粒的工艺。

- 如果您的主要关注点是绝对的工艺纯度和避免污染:您必须投资于高度纯化、密封的石墨等级,或考虑使用钼、钨或先进陶瓷等替代材料。

最终,选择石墨是一个工程决策,它优先考虑其令人难以置信的耐热性,同时承担减轻其对工艺环境影响的责任。

总结表:

| 优点 | 缺点 |

|---|---|

| 卓越的热稳定性(高达3000°C) | 颗粒脱落带来的污染风险 |

| 卓越的能源效率和快速循环 | 真空中蒸汽吸收和放气 |

| 低密度和轻量化,便于操作 | 在对纯度要求严格的工艺中需要仔细管理 |

在为您的实验室工艺选择合适的高温材料时遇到困难? KINTEK 专注于实验室设备和耗材,提供专业的指导和高性能材料,如纯化石墨,以满足您特定的热性能和纯度要求。让我们的专家帮助您平衡性能与污染控制。 立即联系我们,优化您实验室的效率和产品完整性!

图解指南