简单来说,挤压石墨是一种常见的合成石墨,其生产方式是将碳材料的糊状物通过成形模具挤压出来,就像从管子里挤牙膏一样。这个过程使材料的内部晶粒结构对齐,赋予其独特的定向特性。这是一种生产棒材、条材和板材等标准形状的经济有效的方法。

关键要点是挤压过程会产生一种各向异性材料,这意味着其性能(如强度和导电性)会因方向而异。了解这种定向晶粒对于有效使用挤压石墨至关重要。

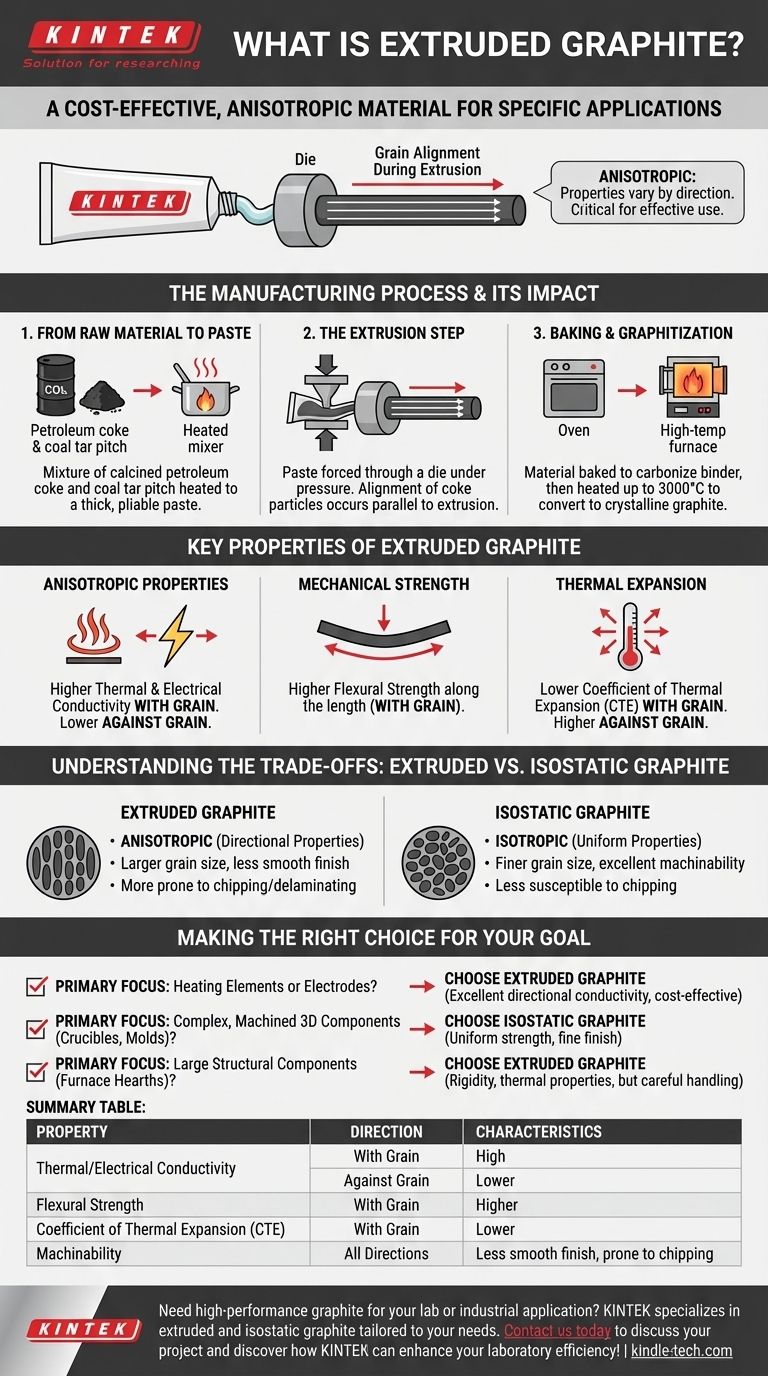

制造工艺及其影响

挤压石墨的独特特性是其制造方式的直接结果。该过程赋予最终材料独特的“晶粒”或取向。

### 从原材料到糊状物

该过程始于煅烧石油焦(主要碳源)和煤沥青(粘合剂)的混合物。将这些材料研磨并混合,然后加热到高温,形成浓稠、有韧性的糊状物。

### 挤压步骤

然后,这种热糊状物在巨大压力下被强制通过一个模具。模具的形状决定了产品的最终横截面,例如圆形棒材或矩形条材。当焦炭的针状颗粒被强制通过模具时,它们会沿着挤压方向平行排列。

### 烘焙和石墨化

挤压后,将“生坯”材料小心地烘烤数周,以使沥青粘合剂碳化并将结构固定到位。最后一步是石墨化,即将碳加热到极高的温度(高达 3000°C),将无定形碳转化为晶体石墨结构。

挤压石墨的关键特性

挤压过程中焦炭颗粒的排列是决定材料行为的最重要因素。

### 各向异性

由于石墨晶体是排列的,其性能沿着晶粒方向和垂直于晶粒方向存在显著差异。当平行于挤压方向(顺晶粒)测量时,热导率和电导率远高于垂直于挤压方向(逆晶粒)测量时的值。

### 机械强度

同样,抗弯强度等机械性能沿着挤压部件的长度方向更高。这种定向强度是关键的设计考虑因素。

### 热膨胀

热膨胀系数 (CTE) 也是方向性的。当沿着晶粒测量时,它通常较低,而当逆着晶粒测量时,它较高。这是涉及高温循环的应用中的一个关键因素。

理解权衡:挤压石墨与等静压石墨

选择正确的石墨类型需要了解制造方法之间的基本权衡。

### 各向异性与各向同性

挤压石墨的主要替代品是等静压石墨(或“等静压成型”)。等静压石墨是通过从所有方向向模具中压制粉末制成的,从而产生随机的晶粒取向。这使其成为各向同性的,意味着其性能在所有方向上都是均匀的。

### 晶粒尺寸和可加工性

与更细粒度的等静压等级相比,挤压石墨通常具有更大的晶粒尺寸。这可能导致机加工表面光洁度不那么光滑,使其不太适合需要复杂细节的应用。

### 易碎性

挤压石墨的晶粒排列结构可能使其更容易崩裂或分层,尤其是在锋利的边缘或处理过程中。这对于炉膛轨道等部件尤其重要,因为在装载和卸载过程中可能会发生机械冲击。

为您的目标做出正确的选择

您的应用特定需求将决定挤压石墨的定向特性是优势还是劣势。

- 如果您的主要重点是加热元件或电极等应用: 挤压石墨出色的定向导电性和成本效益使其成为理想选择。

- 如果您的主要重点是坩埚或模具等复杂的、机加工的 3D 组件: 等静压石墨的均匀强度和精细表面光洁度对于可靠的性能是必需的。

- 如果您的主要重点是炉膛等大型结构部件: 挤压石墨的刚性和热性能是有益的,但其易碎性需要仔细的设计和处理规程。

最终,将材料固有的晶粒结构与您应用的需求相匹配是工程成功的关键。

总结表:

| 特性 | 方向 | 特点 |

|---|---|---|

| 热/电导率 | 顺晶粒 | 高 |

| 热/电导率 | 逆晶粒 | 较低 |

| 抗弯强度 | 顺晶粒 | 较高 |

| 热膨胀系数 (CTE) | 顺晶粒 | 较低 |

| 可加工性 | 所有方向 | 表面光洁度不佳,易崩裂 |

需要用于您的实验室或工业应用的高性能石墨? KINTEK 专注于提供最优质的实验室设备和消耗品,包括根据您的特定需求定制的挤压石墨和等静压石墨。无论您需要具有成本效益的加热元件还是复杂的三维组件,我们的专家都将帮助您选择合适的材料以实现最佳性能和耐用性。立即联系我们 讨论您的项目,了解 KINTEK 如何提高您的实验室效率!

图解指南

相关产品

- 卧式高温石墨真空石墨化炉

- 碳材料石墨化炉石墨真空炉底部出料石墨化炉

- 水热合成反应釜聚四氟乙烯碳纸和碳布纳米生长定制PTFE特氟龙零件制造商

- 用于高精度应用的超高真空电极馈通连接器法兰电源电极引线

- 定制聚四氟乙烯(PTFE)特氟龙培养皿和蒸发皿制造商