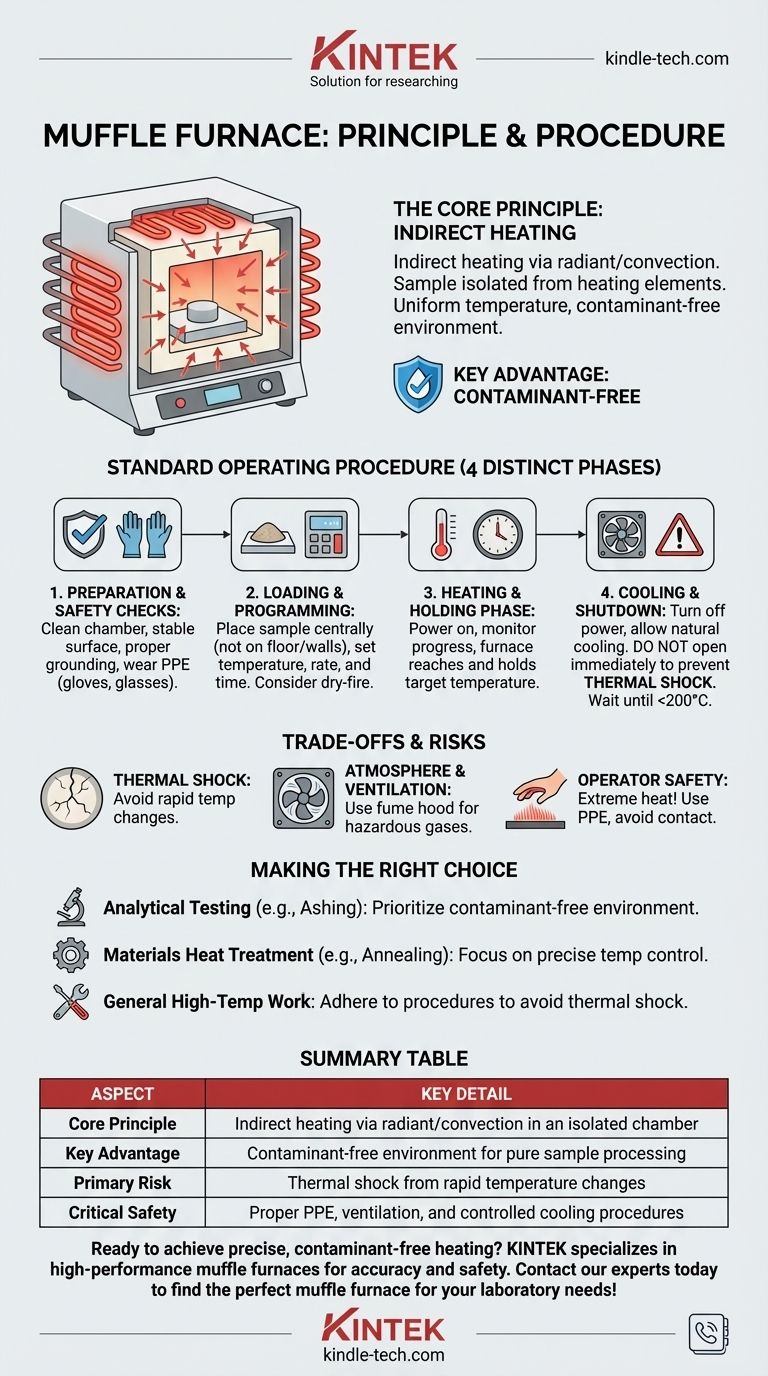

从核心来看,马弗炉的工作原理是间接加热。您希望加热的材料被放置在一个高温腔室,即“马弗”中,然后由外部的电阻加热元件对其进行加热。这种设计将样品与加热元件完全隔离,确保了一个清洁、无污染的环境和高度均匀的温度分布。

马弗炉的主要目的是在完全隔离的环境中提供精确控制的高温加热。这种分离可以保护您的样品免受污染,并确保一致、可重复的结果,但需要严格遵守操作规程以安全管理极端高温。

核心原理:受控隔离

马弗炉不仅仅是一个简单的烤箱。它的设计旨在解决在非常高的温度下实现纯净、均匀加热的特定问题。

“马弗”的定义是什么?

“马弗”是炉子的内腔,通常由高铝耐火陶瓷制成。这种材料旨在承受极端的温度应力,并且是优良的导热体。

加热元件位于该腔室外部,从不与待处理的材料直接接触。

如何实现加热

电加热元件加热马弗腔室本身。腔室随后将热量均匀地向内辐射,通过辐射和对流传热的组合加热样品。

这种间接方法是实现整个处理区域均匀温度分布的关键,防止出现热点。

主要优点:无污染环境

由于样品与加热元件完全隔离,因此不存在来自热源的污染风险。

这对于敏感的实验室程序至关重要,例如灰化、重量分析或材料研究,在这些程序中,样品的纯度对于准确结果至关重要。

标准操作规程

遵循系统化的操作规程对于安全、设备寿命和工作成功至关重要。该过程可分为四个不同的阶段。

步骤1:准备和安全检查

在通电之前,进行彻底的预检查。确保炉腔清洁,没有上次运行留下的任何残留物。

将炉子放置在稳定、平坦的表面上,远离任何易燃材料,并确保其正确接地。始终佩戴适当的个人防护设备(PPE),包括耐热手套和安全眼镜。

步骤2:装载和编程

小心地将样品放入腔室中央,确保它们稳定。切勿将样品直接放在炉底或接触炉壁,因为这会阻碍气流并造成损坏。

牢固关闭炉门。在温度控制器上设置所需的温度,如果适用,还要设置加热速率和保温时间。对于新炉或闲置的炉子,建议在没有样品的情况下进行初始“空烧”,以烧掉任何残留杂质。

步骤3:加热和保温阶段

打开主电源开关。炉子将开始加热至您的设定点,通常由控制器上的指示灯(例如,绿色表示加热)指示。

一旦达到目标温度,炉子将进入“保温”阶段,以在编程的持续时间内保持该温度。监控过程以确保温度保持稳定。

步骤4:冷却和关机

保温时间结束后,关闭控制器上的电源,然后关闭主电源开关。请勿立即打开炉门。

必须让炉子逐渐自然冷却。在腔室处于高温时打开炉门会导致热冲击,这可能会使陶瓷马弗开裂并损坏您的样品。等到温度降至安全水平(通常低于200°C)后再打开炉门取出物品。

了解权衡和风险

虽然马弗炉操作非常有用,但所涉及的高温要求我们尊重并了解潜在的陷阱。

热冲击是主要敌人

炉子损坏最常见的原因是热冲击。这是由于陶瓷部件加热或冷却过快造成的。始终遵循编程的加热斜坡,最重要的是,允许缓慢、自然的冷却。

气氛和通风至关重要

加热某些材料会释放烟雾或气体。始终在通风良好的区域或通风柜下操作炉子,以防止潜在有害气体的积聚。

操作员安全不容谈判

炉子外部会变得非常热。在没有适当个人防护设备的情况下,切勿触摸炉子,并在操作过程中使所有可燃材料远离设备。严格遵守安全协议是操作此设备的唯一方法。

为您的目标做出正确选择

您的具体应用将决定哪些原则和程序对您的成功最关键。

- 如果您的主要重点是分析测试(例如,灰化):无污染环境的原则是您的主要优势;确保每次运行前腔室一尘不染。

- 如果您的主要重点是材料热处理(例如,金属退火):精确的温度控制和均匀加热的原则对于获得所需的材料性能至关重要。

- 如果您的主要重点是一般高温工作:您的首要任务必须是操作规程和安全步骤,特别是避免热冲击,以确保设备的长期可靠性。

通过了解隔离加热的核心原理并一丝不苟地遵循正确的程序,您可以安全有效地利用马弗炉的强大功能。

总结表:

| 方面 | 关键细节 |

|---|---|

| 核心原理 | 通过隔离腔室中的辐射/对流进行间接加热 |

| 主要优点 | 用于纯样品处理的无污染环境 |

| 主要风险 | 温度快速变化引起的热冲击 |

| 关键安全 | 适当的个人防护设备、通风和受控冷却程序 |

准备好在您的实验室中实现精确、无污染的加热了吗?

KINTEK 专注于高性能马弗炉和实验室设备,旨在实现准确性和安全性。无论您是进行灰化、重量分析还是材料研究,我们的解决方案都能确保均匀的温度控制和可靠的结果。

立即联系我们的专家,为您的实验室需求找到完美的马弗炉!

图解指南