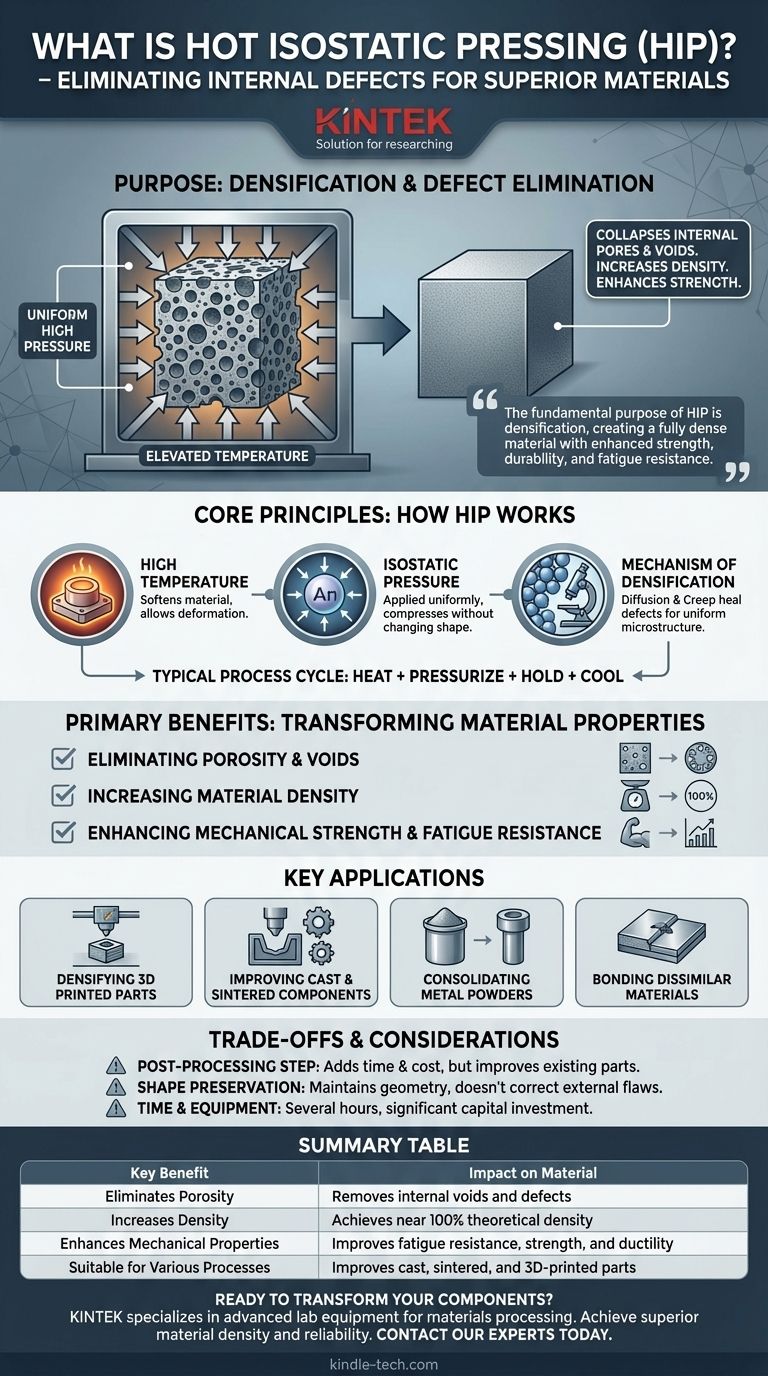

从根本上说,热等静压 (HIP) 是一种旨在消除材料内部缺陷的制造工艺。 它利用高温和均匀高压的组合来压缩和熔合金属、陶瓷或复合材料,有效去除微观空隙并提高材料的密度。这使得部件具有卓越的机械性能和可靠性。

HIP 的基本目的是致密化。通过在高温下对部件施加均匀的高压气体,该工艺会使内部气孔和空隙塌陷,从而形成具有增强的强度、耐用性和抗疲劳性的完全致密的材料。

热等静压的工作原理:核心原理

要了解 HIP 的优势,必须掌握其核心机制。该工艺依赖于对温度、压力和受控气氛这三个关键要素的精确控制。

高温的作用

部件在 HIP 腔室内加热至低于其熔点的温度。这种热量会软化材料,使其在压力下易于发生塑性变形。

等静压的作用

同时,腔室被填充惰性高压气体,通常是氩气。这种压力是等静的,意味着它从所有方向均匀施加,确保部件在压缩过程中不会改变其净形状。

致密化的机制

热量和压力的结合导致材料内部的空隙或气孔塌陷。在原子层面上,这种压力促使材料扩散并蠕变进入空隙,从而永久修复缺陷并形成坚实、均匀的微观结构。

典型的工艺循环

标准的 HIP 循环包括将部件装入容器、将其加热到目标温度、加压腔室、在设定的持续时间内保持这些条件,最后是受控的减压和冷却阶段。整个过程可以与其他热处理步骤(如淬火和时效)相结合,以整合制造阶段。

主要优势:改变材料性能

消除内部孔隙率不仅仅是表面修复;它从根本上改变了材料的性能特征,使其适用于苛刻的应用。

消除孔隙和空隙

HIP 最直接的结果是消除内部缺陷。这对于通过铸造、烧结或增材制造(3D 打印)制造的部件尤为关键,这些部件通常容易出现微观孔隙。

提高材料密度

通过使空隙塌陷,HIP 使材料趋向于100% 理论密度。这种均匀的密度与改善的、更可预测的材料性能直接相关。

增强机械强度和抗疲劳性

孔隙充当裂纹可能萌生和扩展的应力集中点。通过消除这些缺陷,HIP 大幅提高了部件的抗疲劳性、延展性和整体拉伸强度。

跨制造的关键应用

HIP 不是一种独立的制造方法,而是一种强大的后处理步骤,可以增强通过其他方式制造的部件。

致密化 3D 打印(增材)部件

增材制造通常会产生具有内部孔隙率或层间结合不完美的部件。HIP 是对这些部件进行致密化的关键步骤,使其适用于航空航天和医疗行业的高应力应用。

改进铸件和烧结部件

传统的铸造和烧结可能会留下残留的孔隙率。HIP 用于修复这些内部缺陷,挽救了可能被报废的部件,并提升了其性能。

金属粉末的固结

HIP 可用于将金属粉末固结成完全致密的固体。将粉末放置在密封的金属容器或“罐”中,然后对其进行 HIP 循环处理,从而制造出性能可超过传统锻造材料的“近净形”部件。

粘合不同材料

HIP 过程的强烈压力和热量也可用于在两种或多种不同材料之间形成牢固的、基于扩散的粘合,从而能够制造出复杂的包覆组件。

了解权衡和注意事项

尽管 HIP 非常有效,但它是一个特定的工具,具有自己的一套操作现实。了解这些是正确应用它的关键。

它是一个后处理步骤

HIP 不制造部件;它改进现有部件。它会增加整体制造工作流程的时间和成本,这必须通过对增强材料性能的需求来证明。

形状保持,而非重塑

压力的等静特性确保部件的整体几何形状得以保持。它不会纠正外部尺寸不准确或表面缺陷;它只解决内部缺陷。

工艺时间和设备

HIP 循环可能需要数小时,而设备代表着巨大的资本投资。这使得该工艺最适合对性能和可靠性有不可妥协要求的高价值部件。

为您的目标做出正确的选择

应用 HIP 应是一个由特定性能要求驱动的深思熟虑的决定。

- 如果您的主要重点是关键部件的最大性能: 使用 HIP 消除航空航天、医疗或能源部件中的所有内部缺陷,以保证可靠性和疲劳寿命。

- 如果您的主要重点是改进增材制造的部件: 将 HIP 指定为强制性的后处理步骤,以实现功能性、承重应用所需的机械性能。

- 如果您的主要重点是从金属粉末制造完全致密的部件: 采用粉末冶金 HIP 路线来生产具有卓越、均匀材料性能的近净形部件。

- 如果您的主要重点是挽救具有内部孔隙率的铸件: 实施 HIP 来修复铸造缺陷,提高成品率并确保最终部件的结构完整性。

最终,热等静压作为最后一步,通过完善部件的内部结构,将良好的部件转变为卓越的部件。

摘要表:

| 关键益处 | 对材料的影响 |

|---|---|

| 消除孔隙率 | 去除内部空隙和缺陷 |

| 提高密度 | 达到接近 100% 的理论密度 |

| 增强机械性能 | 提高抗疲劳性、强度和延展性 |

| 适用于各种工艺 | 改进铸造、烧结和 3D 打印的部件 |

准备好通过热等静压改变您的部件了吗?

KINTEK 专注于先进的材料加工实验室设备和耗材。我们的专业知识可以帮助您集成 HIP 技术,为您在航空航天、医疗和能源应用中最关键的部件实现卓越的材料密度、增强的机械性能和无与伦比的可靠性。

立即联系我们的专家,讨论我们的解决方案如何满足您的特定实验室和制造需求。

图解指南

相关产品

- 高压应用用温等静压 WIP 工作站 300Mpa

- 固态电池研究用温等静压机

- 手动高温加热液压压机带加热板用于实验室

- 带加热板的自动加热液压压机,用于实验室热压

- 带加热板的自动高温加热液压压机,用于实验室