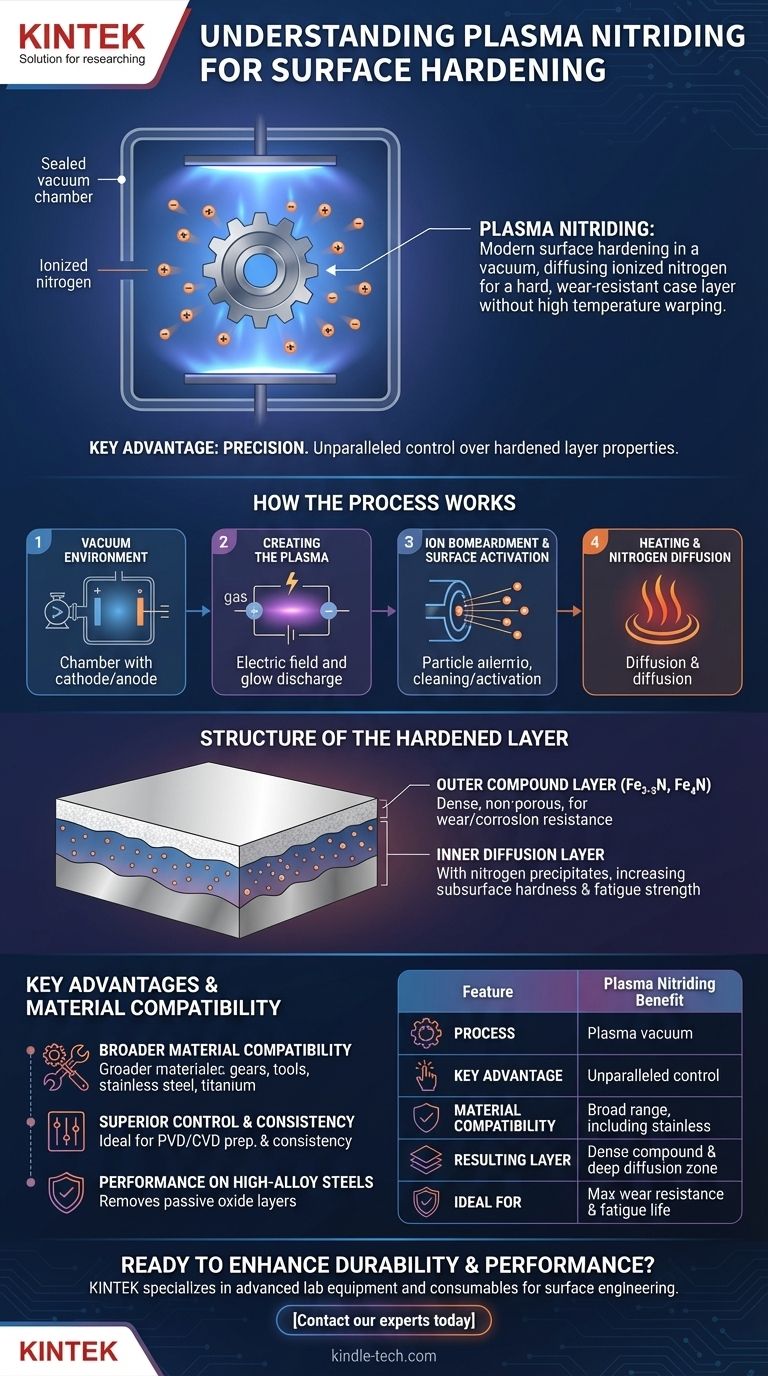

简而言之,等离子氮化是一种现代表面硬化方法,它利用真空中的氮电离气体将氮扩散到金属表面。这会形成一个极其坚硬且耐磨的表层,而不会产生可能导致零件变形的高温或淬火过程。

等离子氮化的关键优势在于其精确性。通过使用电场来控制工艺,工程师可以对硬化层的特性获得无与伦比的控制,使其在高性能和敏感部件方面优于传统方法。

等离子氮化工艺的工作原理

等离子氮化,也称为离子氮化,是一种热化学热处理,它从根本上改变材料的表面。该过程完全在一个密封的真空室中进行。

真空环境

待处理的工件放置在腔室内部,并成为阴极(负电荷)。炉壁本身充当阳极(正电荷)。然后对腔室进行抽真空以去除任何污染物。

产生等离子体

将特定的含氮气体混合物引入腔室。在工件和炉壁之间施加高压电场,导致气体电离并形成一种低压、导电的气体,称为等离子体。这在视觉上表现为围绕工件的特征性辉光放电。

离子轰击和表面活化

等离子体中带正电的氮离子以高能量被加速射向带负电的工件。这种离子轰击具有几个同时发生的作用。

首先,它会在微观层面上溅射表面,将其中的任何杂质清洁掉,并溶解钝化氧化层,这对不锈钢尤其关键。这会使表面活化,使其高度易于接受氮气。

加热和氮扩散

离子轰击产生的恒定能量传递也会将工件加热到所需的氮化温度。一旦达到温度,活化的表面就会很容易地允许氮原子扩散到材料内部,从而开始硬化过程。

硬化层的结构

氮化过程会在材料表面形成一个明显的、两部分的硬化层,每一部分都有特定的功能。

外层化合物层

这是最外层,通常称为“白层”。它由硬质氮化铁化合物(ε-氮化物 Fe2-3N 和 γ'-氮化物 Fe4N)组成。在等离子氮化中,这一层独特地致密且无孔,可提供卓越的耐磨损、耐摩擦和耐腐蚀性。

内扩散层

在化合物层之下是扩散层。在这里,氮已经深入渗透到基体材料中。它与合金中形成氮化物的元素(如铬、钼和铝)形成细小的析出物,从而显著提高部件的亚表面硬度和疲劳强度。

了解关键优势

与气体氮化或盐浴氮化等旧方法相比,等离子氮化具有显著优势,尤其适用于要求严苛的应用。

更广泛的材料兼容性

该工艺对各种材料都有效。这包括所有黑色金属、高合金工具钢、铸铁,甚至那些通常难以氮化的材料,如不锈钢、镍基合金和钛合金。

卓越的控制和一致性

等离子体的电学参数可以精确控制。这使得可以微调氮化层的结构,例如形成特定的化合物层厚度,甚至形成完全没有化合物层的结构,这非常适合后续的 PVD 或 CVD 涂层。

对高合金钢的性能

对于高合金钢和不锈钢,等离子体的溅射效应至关重要。它能有效去除那些会阻碍氮扩散的坚硬钝化氧化层,从而比气体氮化获得更硬、更一致的表层。

为您的目标做出正确的选择

了解这些原理可以帮助您为特定的工程挑战选择正确的表面处理方法。

- 如果您的主要关注点是最大的耐磨损和抗咬合性: 等离子氮化形成的致密、无孔的化合物层为齿轮、挤出机螺杆和锻模等部件提供了卓越的性能。

- 如果您的主要关注点是提高部件的疲劳寿命: 深层扩散层显著提高了亚表面强度,使其非常适合曲轴、凸轮轴和车轴。

- 如果您的主要关注点是处理不锈钢或高合金工具钢: 等离子氮化是明确的选择,因为其表面活化机制可以克服这些材料固有的钝化层。

- 如果您的主要关注点是为薄膜涂层准备表面: 精确控制或消除化合物层的能力使等离子氮化成为 PVD 和 CVD 工艺的理想准备步骤。

最终,利用等离子氮化可以实现更高水平的材料表面工程,从而有助于设计出更耐用、更高效、更可靠的部件。

摘要表:

| 特性 | 等离子氮化的益处 |

|---|---|

| 工艺 | 在真空室中使用电离气体(等离子体) |

| 关键优势 | 对硬化层特性具有无与伦比的控制力 |

| 材料兼容性 | 范围广泛,包括不锈钢和高合金工具钢 |

| 形成的层 | 致密的无孔化合物层和深层扩散区 |

| 理想用途 | 需要最大耐磨性和疲劳寿命的部件 |

准备好提高部件的耐用性和性能了吗?

KINTEK 专注于表面工程的先进实验室设备和消耗品。我们在等离子氮化技术方面的专业知识可以帮助您为高性能部件实现卓越的耐磨性、耐腐蚀保护和延长的疲劳寿命。

立即联系我们的专家,讨论等离子氮化如何解决您的特定材料挑战并提高您的产品可靠性。

图解指南