是的,您绝对可以将两种不同的金属进行钎焊。事实上,连接不同材料是钎焊过程的主要优势之一。这种方法允许您使用熔点低于所连接的两种母材的填充金属,来连接各种金属——包括钢、铜、镍、铝,甚至是陶瓷。

核心原则很简单:虽然几乎任何两种金属都可以钎焊,但接头的成功完全取决于填充金属“润湿”并粘合到两个表面的能力,这个过程需要仔细清洁和控制表面氧化物。

基本原理:“润湿性”

钎焊通过毛细作用工作,熔融的填充金属被吸入两个母材之间的狭窄间隙中。要实现这一点,填充金属必须能够“润湿”表面。

什么是润湿性?

将润湿性想象成水在干净的玻璃板上铺展开来的方式,与水在打蜡的汽车上形成水珠的方式。要获得牢固的钎焊接头,熔融的填充金属必须在两个母材表面上平稳铺展,并完全粘附在它们上面。

表面氧化物的作用

几乎所有金属暴露在空气中时都会形成一层看不见的氧化物层。这层氧化物像一个屏障,阻止填充金属与母材直接接触,从而阻止润湿。

克服氧化物屏障

为了实现成功的钎焊,您必须去除氧化物层,并在加热过程中防止其重新形成。这主要通过两种方式实现:

- 焊剂 (Flux): 在加热前涂敷在接头区域的化合物。焊剂熔化,溶解氧化物,并保护接头免受大气影响。

- 受控气氛: 在充满特定气体(如氢气)的炉内或真空下进行钎焊。这种气氛会化学去除氧化物或从一开始就阻止其形成。

常见的异种金属组合

钎焊具有极高的通用性,但有些组合比其他组合更直接。

钢、铜和镍合金

这些材料通常可以非常成功地相互钎焊。它们的氧化物相对容易控制,而且许多标准填充金属(通常是银或铜基合金)与它们兼容。

铝的挑战

铝可以与其他金属(如钛、镍和铍)钎焊。然而,其顽固的氧化物层和低熔点需要特殊的焊剂和精确的温度控制。

值得注意的是,铝不能使用标准技术直接钎焊到铜或黄铜上。这些组合需要特殊的措施,例如用镍等更兼容的材料对其中一种金属进行预电镀。

先进材料:陶瓷和难熔金属

钎焊的原理甚至扩展到了非金属。只要填充合金能够润湿两个表面,陶瓷就可以与金属钎焊。难熔金属(如钨)通常使用专业的真空钎焊技术与活性金属(如钛)连接,以防止任何污染。

理解关键考虑因素

连接两种不同的金属会带来必须管理的复杂性,以确保接头可靠。

填充金属的兼容性

填充金属是两种材料之间的桥梁。其熔点必须低于两种母材,以确保它们在过程中不会熔化。它还必须与两者在化学上兼容,才能形成牢固的冶金结合。

管理热膨胀

不同材料在加热和冷却时膨胀和收缩的速率不同。如果这种差异(热膨胀系数)很大,当接头冷却时,可能会对它产生巨大的应力,从而可能导致其开裂或失效。这必须通过工艺设计和加热/冷却速率来管理。

避免电偶腐蚀

当两种不同的金属在电解质(如湿气)存在下接触时,它们会形成一个电偶电池,导致其中一种金属快速腐蚀。填充金属的选择会影响这种影响,因此对于打算在某些环境中长期使用的部件来说,这是一个关键的考虑因素。

为您的目标做出正确的选择

您的方法完全取决于您需要连接的材料以及您要求的性能。

- 如果您的主要重点是通用制造(例如,钢对铜): 标准的银基填充金属和化学焊剂通常足以形成牢固的结合。

- 如果您的主要重点是连接活性金属(例如,铝对钛): 您将需要专为铝设计的特殊焊剂或受控气氛炉,以及兼容的填充合金。

- 如果您的主要重点是高性能应用(例如,难熔金属): 这些要求苛刻的接头几乎总是需要专业的真空炉钎焊,以确保纯度和接头完整性。

通过理解这些核心原理,您可以自信地使用钎焊技术在各种不同的材料之间创建牢固、可靠的接头。

摘要表:

| 关键考虑因素 | 对异种金属的重要性 |

|---|---|

| 填充金属润湿性 | 填充金属必须流动并粘合到两个金属表面上才能形成牢固的接头。 |

| 热膨胀 | 不同的膨胀速率会导致应力;必须控制加热/冷却过程。 |

| 电偶腐蚀 | 接触的异种金属会腐蚀;填充金属的选择可以减轻这种风险。 |

| 氧化物去除 | 必须使用焊剂或受控气氛(例如真空)去除表面氧化物。 |

需要连接两种不同金属并形成牢固、可靠的接头吗?正确的设备对于控制钎焊气氛和温度至关重要。KINTEK 专注于实验室设备和耗材,包括钎焊炉,以帮助您获得完美的结果。让我们的专家帮助您为您特定的材料和应用选择理想的解决方案。 立即联系我们进行咨询!

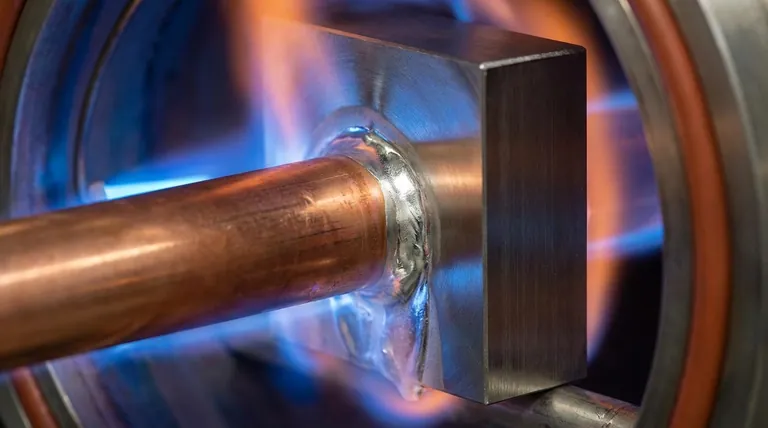

图解指南