是的,从实际意义上讲,陶瓷在压力下异常坚固。 这并非因为材料的内部特性发生变化,而是因为压缩力中和了导致陶瓷脆性的微观缺陷。当你挤压陶瓷时,你实际上是在闭合那些微小的、固有的裂纹,这些裂纹在拉力作用下会导致陶瓷破碎。

陶瓷在压缩下的巨大强度并非材料本身的变化。相反,压缩载荷有效地消除了材料最大的弱点——预先存在的微观缺陷——使其强大的原子键能够直接承受载荷。

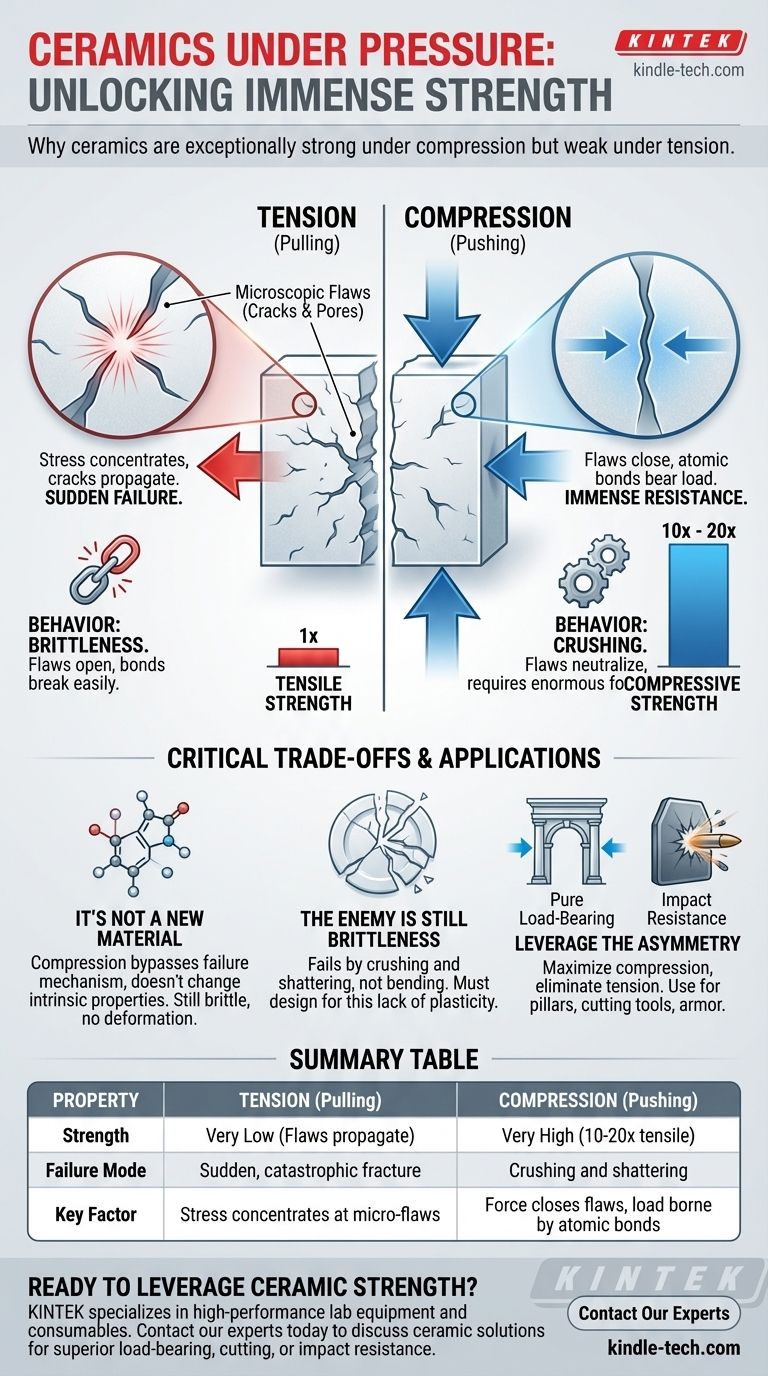

为什么压缩和拉伸对陶瓷来说是截然不同的世界

要理解这种行为,你必须从微观层面审视材料。答案在于陶瓷强大的原子结构与其不可避免的微小缺陷之间的相互作用。

陶瓷的结构

每种陶瓷材料,无论制造得多么精良,都含有微观缺陷。这些缺陷可以是微小的孔隙、晶界,或在加工或冷却过程中引入的微小裂纹。

虽然将陶瓷原子结合在一起的离子键和共价键非常坚固,但这些缺陷却成为弱点。

拉伸(拉开)下的行为

当你拉伸陶瓷时,所有的拉伸应力都集中在这些微观缺陷的尖端。这种强烈的集中作用就像一个微小的楔子,很容易将原子键撕裂。

裂纹开始生长,或称扩展,由于材料非常坚硬,裂纹几乎瞬间穿过整个物体。这就是为什么陶瓷在拉伸下以很小的力就会突然且灾难性地失效,这种行为我们称之为脆性。

压缩(推压)下的行为

当你推压陶瓷时,情况恰恰相反。压缩力将这些微观缺陷的两侧推合在一起,有效地闭合了它们。

随着这些弱点的中和,材料的强度不再由其缺陷决定。相反,载荷由整个原子结构及其强大的化学键承受。只有当力大到足以压碎这种结构时才会发生失效,这需要巨大的能量。

关键的权衡和局限性

虽然其抗压强度是一个巨大的优势,但了解这一特性的背景和局限性对于有效使用陶瓷至关重要。

它并非变得本质上更坚固

处于压缩状态的陶瓷并非一种新的或改进的材料。其基本特性并未改变。载荷方式——压缩——只是绕过了其主要的失效机制。

如果你将同一块受压陶瓷施加少量拉伸(例如,通过弯曲),它仍然会以其典型的低拉伸强度失效。

敌人仍然是脆性

即使在极端压缩下,陶瓷仍然是脆性的。它们在失效前不会像金属那样弯曲、拉伸或变形。

当它们达到其压缩极限时,它们会因压碎和破碎而失效。这种缺乏塑性变形是一个必须始终考虑的关键设计限制。

两种强度的故事

这种差异并非微不足道。典型工程陶瓷的抗压强度可能是其抗拉强度的10到20倍。

这种巨大的不平衡是设计这些材料时需要理解的最重要的机械特性。这正是古罗马拱门和现代混凝土大坝如此有效的原因——它们被设计成使陶瓷材料完全处于压缩状态。

如何利用陶瓷强度在您的应用中

您的设计策略必须完全围绕这种不对称性构建。目标始终是最大化压缩同时消除拉伸。

- 如果您的主要关注点是纯粹的承重: 陶瓷在支撑柱、切削工具和防弹装甲板等应用中提供无与伦比的性能,这些应用中主要受力是压缩。

- 如果您的应用涉及任何弯曲或拉伸: 您必须设计系统以隔离陶瓷免受拉伸应力,通常通过在复合结构中使用它,其中另一种材料(如混凝土中的钢筋)承受拉伸。

- 如果目标是抗冲击性: 认识到陶瓷通过破碎吸收冲击能量。在防弹衣等应用中,这是一个特点,而不是缺陷,因为陶瓷板破碎以耗散弹丸的动能。

理解压缩和拉伸行为之间的这种根本差异是成功使用陶瓷材料进行工程设计的关键。

总结表:

| 属性 | 拉伸(拉开)下的行为 | 压缩(推压)下的行为 |

|---|---|---|

| 强度 | 非常低(缺陷扩展裂纹) | 非常高(拉伸强度的10-20倍) |

| 失效模式 | 突然的、灾难性断裂 | 压碎和破碎 |

| 关键因素 | 应力集中在微观缺陷处 | 力闭合缺陷,载荷由原子键承受 |

准备好在您的实验室或制造过程中利用陶瓷巨大的抗压强度了吗? KINTEK 专注于高性能实验室设备和耗材,包括专为最大耐用性和效率设计的陶瓷组件。我们的专业知识确保您获得适用于需要卓越承重、切割或抗冲击性能的应用的正确材料。立即联系我们的专家,讨论我们的陶瓷解决方案如何提升您项目的性能和可靠性。

图解指南

相关产品

- 实验室用双板加热压制模具

- 高压应用用温等静压 WIP 工作站 300Mpa

- 实验室液压压片机 纽扣电池压片机

- 实验室灭菌器 实验室高压蒸汽灭菌器 液体显示自动型立式压力蒸汽灭菌器

- 实验室灭菌器 实验室高压灭菌器 脉冲真空升降灭菌器