机械性能概述

强度和硬度

陶瓷材料以其卓越的强度和硬度而闻名,这主要归功于其强大的离子和共价键结构。这种结合机制使陶瓷的硬度经常超过 1500HV,这是许多材料无法达到的。例如,氧化锆陶瓷的硬度超过 9 级,在硬度方面仅次于金刚石。

陶瓷的高硬度不仅仅是一个理论上的优势,而是一个实际的优势,它对陶瓷的耐用性和抗磨损性产生了重大影响。陶瓷的这一特性使其非常适合在恶劣条件下保持材料完整性的应用,如切削工具、装甲电镀和高性能机械部件。

此外,陶瓷的强度(通常以其承受压缩力的能力来衡量)同样令人印象深刻。这种强度加上硬度,使陶瓷在许多高压力环境中成为金属等传统材料的优越替代品。陶瓷独特的原子结构具有强共价键和离子键的特点,这确保了陶瓷即使在极端的机械应力下也能保持结构的完整性。

总之,陶瓷材料的强度和硬度是其广泛应用于需要高性能、耐用材料的行业的基础。陶瓷材料的抗变形和抗磨损能力,再加上其优异的抗压强度,使其在许多关键应用中更具优势。

缺乏塑性和韧性

尽管陶瓷具有很高的抗压强度,但其抗拉强度却很低,塑性和韧性也很差。造成这一缺陷的主要原因是其复杂的晶体结构限制了可用滑移系统的数量。滑移系统对塑性变形至关重要,可使材料在应力作用下发生塑性变形而不会断裂。然而,陶瓷的原子排列复杂,滑移系统数量有限,因此很难发生塑性变形。

此外,在陶瓷中产生位错需要很高的能量,这进一步加剧了陶瓷缺乏塑性的问题。位错是晶格中的线状缺陷,可使原子相互滑动,从而实现塑性变形。与金属相比,陶瓷产生这些位错所需的能量要高得多,因为金属在应力作用下很容易产生和传播位错。这种高位错生成能导致陶瓷脆性,使其在拉伸应力下容易发生灾难性的破坏。

总之,复杂的晶体结构、有限的滑移系统和高位错生成能共同导致了陶瓷材料的拉伸强度低、塑性和韧性差。

机械性能指标

关键指标

在评估瓷砖应用时,必须仔细评估几个关键指标,以确保最佳性能和耐用性。 尺寸偏差 和 表面质量 是基础,因为它们直接影响瓷砖的贴合度和美观度。 吸水性 是另一个关键因素,因为随着时间的推移,吸水率过高会导致褪色、翘曲和结构退化。

瓷砖的 断裂模数 和 断裂强度 是衡量瓷砖在载荷作用下抗弯曲和抗断裂能力的基本机械性能。这些指标在瓷砖反复受力的高人流量区域尤为重要。 抗热震性 对于暴露在温度波动环境中的瓷砖(如室外或工业环境中使用的瓷砖)至关重要,可确保瓷砖能够承受热循环而不会开裂。

最后是耐磨性、 耐磨性 对于保持瓷砖表面的完整性和使用寿命至关重要,尤其是在人流量大或使用磨损性材料的地方。在确定瓷砖的整体质量和各种应用的适用性方面,这些指标各具特色,但又相互关联。

| 指标 | 重要性 |

|---|---|

| 尺寸偏差 | 确保适当的贴合度和外观 |

| 表面质量 | 影响美观和触感 |

| 吸水性 | 防止褪色、翘曲和结构退化 |

| 断裂模数 | 测量负载下的抗弯强度 |

| 断裂强度 | 测量在载荷作用下的断裂阻力 |

| 抗热震性 | 确保在温度波动下的耐用性 |

| 耐磨性 | 在磨损情况下保持表面完整性 |

这些指标共同决定了瓷砖的机械和结构完整性,指导生产商和消费者为特定应用选择最合适的材料。

与金属的比较

与金属相比,陶瓷具有出色的弹性模量和硬度。这主要是由于陶瓷具有很强的离子键和共价键,因此硬度值通常超过 1500 HV,氧化锆陶瓷的硬度超过 9,仅次于钻石。然而,这种令人印象深刻的硬度是有代价的:陶瓷的抗拉强度明显较低,室温下的塑性变形几乎可以忽略不计。金属在失效前会发生很大的塑性变形,而陶瓷则不同,它仍然很脆,因此在拉伸应力下很容易发生灾难性的断裂。

| 特性 | 陶瓷 | 金属 |

|---|---|---|

| 弹性模量 | 较高 | 较低 |

| 硬度 | 较高 | 较低 |

| 拉伸强度 | 较低 | 较高 |

| 塑性变形 | 几乎没有 | 显著 |

性能上的这种对立凸显了陶瓷和金属在机械行为上的根本差异。虽然陶瓷非常适合需要高硬度和耐磨性的应用,但由于其缺乏塑性和韧性,限制了其在拉伸强度和延展性至关重要的情况下的应用。了解这些权衡因素对于为特定工程应用选择合适的材料至关重要。

影响机械性能的因素

温度的影响

温度在决定陶瓷的机械行为方面起着关键作用,尤其是影响其弹性模量。随着温度的升高,陶瓷结构中的原子间距会因热膨胀而增大。这种膨胀会导致弹性模量的降低,因为原子间的作用力会随着原子间距的增加而减弱,从而产生刚度。这种现象可以形象地理解为,材料在加热过程中变得更加顺从,刚度降低。

例如,在燃气轮机或熔炉等高温应用中,陶瓷的热膨胀会显著改变其机械性能。在高温条件下,弹性模量的降低会影响材料承受机械应力的能力,如果在设计阶段没有考虑到这一点,就有可能导致结构失效。

| 温度范围 | 弹性模量变化 | 影响 |

|---|---|---|

| 室温 | 高弹性模量 | 出色的刚度和抗变形能力 |

| 温度升高 | 弹性模量降低 | 刚度降低,受力变形可能增大。 |

温度与弹性模量之间的关系不是线性的,而是受特定材料成分和微观结构影响的复杂模式。先进陶瓷材料(如航空航天工程中使用的材料)通常要经过严格的热分析,以预测和减轻这些影响,确保其在极端条件下的性能。

总之,虽然陶瓷在环境温度下具有优异的机械性能,但在较高温度下,由于原子间距的变化,其性能会显著下降。要在各种高温应用中有效使用陶瓷,了解和管理这种随温度变化的行为至关重要。

孔隙率的作用

孔隙率在决定陶瓷的弹性模量方面起着关键作用,孔隙率的高低与材料的机械性能直接相关。随着孔隙率的增加,陶瓷的弹性模量会急剧下降。这种现象可归因于材料中存在空隙,空隙是应力的集中点,导致陶瓷的整体刚度和强度降低。

先进的烧结技术已成为减轻孔隙率不利影响的有效方法。这些技术包括热等静压(HIP)和现场辅助烧结技术(FAST),可显著降低陶瓷中的孔隙率水平。通过最大限度地减少这些空隙,陶瓷的机械性能(如弹性模量和整体强度)可得到大幅提高。

| 烧结技术 | 对孔隙率的影响 | 对弹性模量的影响 |

|---|---|---|

| 热等静压 (HIP) | 通过施加均匀的压力降低孔隙率 | 提高弹性模量 |

| 现场辅助烧结技术 (FAST) | 提高致密性 | 提高机械性能 |

总之,虽然孔隙率对陶瓷的机械完整性构成了重大挑战,但现代烧结工艺提供了可行的解决方案,可提高陶瓷的结构和机械性能。

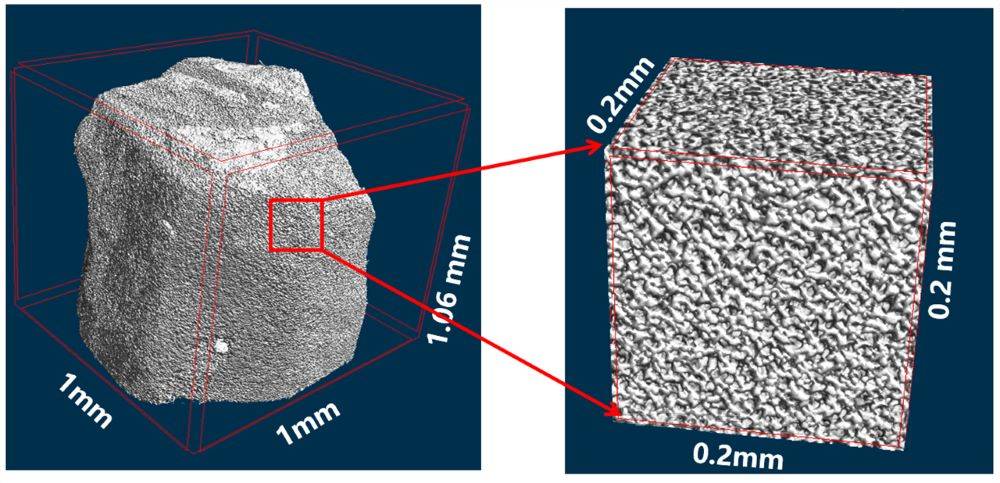

晶粒尺寸效应

陶瓷中较小的晶粒尺寸是显著增强其强度的关键因素。这一现象可归因于霍尔-佩奇(Hall-Petch)关系,即随着晶粒尺寸的减小,材料的屈服强度会增加。这主要是由于晶界数量增加,晶界成为位错运动的障碍,从而阻碍了塑性变形。

然而,陶瓷强度的提高并不仅仅取决于晶粒尺寸。杂质和孔隙率等其他因素在决定陶瓷的整体机械性能方面也起着重要作用。杂质可充当应力集中器,导致局部薄弱环节,从而可能导致失效。另一方面,孔隙率会大大降低材料的密度,从而降低其机械完整性。较高的孔隙率会导致弹性模量和整体强度急剧下降,因为材料结构中空隙的存在会削弱其承载能力。

为了说明晶粒大小与这些其他因素之间的相互作用,请看下表:

| 因素 | 对强度的影响 | 机理 |

|---|---|---|

| 晶粒尺寸 | 正 | 晶界增大阻碍位错运动 |

| 杂质 | 负 | 应力集中,导致局部缺陷 |

| 孔隙率 | 负 | 降低材料密度,导致承载能力下降 |

总之,虽然减小晶粒尺寸是提高陶瓷强度的有效策略,但必须同时尽量减少杂质和孔隙率,以达到最佳机械性能。先进的烧结工艺,如热压和火花等离子烧结,可用于减少孔隙率和细化晶粒尺寸,从而提高陶瓷材料的整体强度和耐用性。

提高机械性能的方法

添加纳米材料

事实证明,在陶瓷材料中加入纳米氧化铝是提高其整体性能的变革性策略。通过加入这些纳米级颗粒,烧结过程可以得到显著优化。具体来说,纳米氧化铝的加入降低了所需的烧结温度,这不仅降低了能耗,还最大限度地减少了制造过程中的热降解风险。

此外,加入纳米氧化铝后,陶瓷材料的致密性明显提高。这种致密性的提高会导致微观结构更加均匀和紧凑,这对于提高材料的机械性能至关重要。微观结构的改善可转化为更高的抗弯强度和断裂韧性,使陶瓷在面对机械应力和突然冲击时更具弹性。

总之,战略性地添加纳米氧化铝不仅能简化生产工艺,还能赋予陶瓷材料卓越的机械性能,使其在各种工业应用中更具通用性和可靠性。

束缚效应的强化作用

约束效应包括横向约束和覆盖约束,在增强陶瓷的机械性能方面发挥着关键作用,尤其是在压缩加载条件下。这种效应利用陶瓷固有的脆性来减缓断裂扩展,从而显著提高陶瓷的整体强度。

横向约束通常通过施加外力或设计材料结构来实现,其作用是限制陶瓷材料在受到压缩力时的横向膨胀。这种限制可防止形成可能导致灾难性失效的微裂缝。同样,可通过使用保护涂层或封装来实现的覆盖限制可使陶瓷免受环境因素的影响,这些因素可能会诱发应力并促进裂纹的产生。

约束在防止脆性断裂方面的有效性已得到充分证明。例如,在工业机械或航空航天应用等高应力环境中,约束效应可将陶瓷的失效行为从突发的灾难性事件转变为更受控制的渐进过程。这种转变不仅能提高陶瓷元件的可靠性,还能延长其使用寿命。

此外,横向约束和覆盖约束的结合可以产生协同效应,放大每种方法的优势。这种双重方法可确保陶瓷材料即使在极端条件下也能保持坚固和弹性。这样,陶瓷材料不仅能保持较高的抗压强度,还能提高抗断裂性能,从而适用于更多要求苛刻的应用领域。

新方法

将二维石墨烯阵列嵌入陶瓷基体是增强机械性能的一种突破性方法。这种方法利用了石墨烯独特的结构特性,而石墨烯是一种以优异强度和柔韧性著称的材料。通过集成这些石墨烯阵列,陶瓷基体发生了脱胎换骨的变化,从灾难性断裂状态转变为稳定的传播行为。这种整合不仅大大提高了陶瓷的机械韧性和强度,还引入了一种更可控、更可预测的断裂机制。

这一过程包括在陶瓷结构中仔细排列石墨烯片,形成一个能更有效地吸收和分散应力的网络。这种排列对于最大限度地发挥石墨烯的优势至关重要,因为它能确保材料的固有特性得到充分利用。因此,这种陶瓷材料具有优异的抗裂纹产生和扩展能力,非常适合对耐用性和可靠性要求极高的应用领域。

此外,添加石墨烯阵列还能从多方面改善机械性能。例如,增强的韧性可使材料在失效前承受更高的应力水平,而增强的强度则可确保材料在不变形的情况下承受更大的负荷。这种双重增强不仅拓宽了陶瓷的应用范围,还为材料科学的研发开辟了新途径。

总之,将二维石墨烯阵列集成到陶瓷基体中提供了一种新颖而有效的方法,可显著提高机械韧性和强度,从而改变陶瓷的断裂行为,为制造更坚固可靠的材料铺平道路。

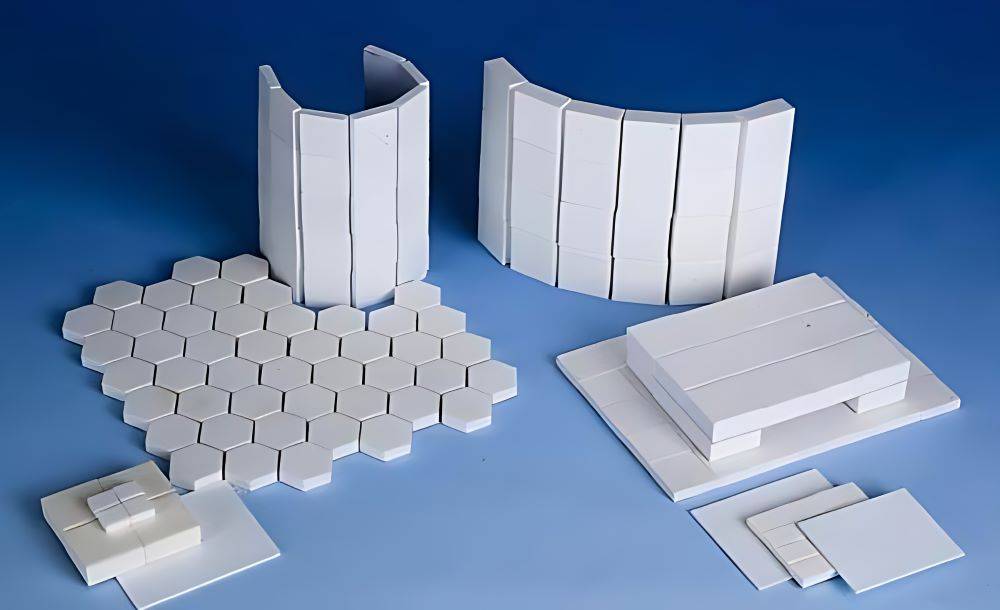

相关产品

- 精密加工氧化锆陶瓷球,用于工程先进精细陶瓷

- 工程高级陶瓷镊子带尖头弯头氧化锆陶瓷尖端

- 精密加工氧化钇稳定氧化锆陶瓷板用于工程先进精细陶瓷

- 定制氧化铝氧化锆特种异形陶瓷板用于工程先进精细陶瓷加工

- 定制氮化硼(BN)陶瓷件