精细陶瓷

高品质氧化铝陶瓷螺钉,用于工程先进陶瓷,耐高温绝缘

货号 : KM-C011

价格根据 规格和定制情况变动

- 材质

- 氧化锆铝

- 规格

- 见表格

运输:

联系我们 获取运输详情 享受 准时发货保证.

为什么选择我们

简易的订购流程、优质的产品和专业的支持,助力您的业务成功。

应用

氧化铝陶瓷螺钉由高纯度氧化铝或碳化硅制成。以其高硬度和高强度而闻名。可承受高达1500°C的连续使用温度。具有优异的耐热性、耐化学性和电绝缘性。陶瓷部件可在极端温度下保持不变形或机械性能损失。与金属部件相比,它们具有电绝缘性和轻质性。

- 航空航天:用于电子设备的绝缘、抗干扰、轻质和耐高温。

- 电子设备:为电子设备提供绝缘、抗干扰、轻质等特性。

- 医疗设备:无磁性、环保、绝缘、抗干扰、安全性增强。

- 石化行业:耐高温、耐化学腐蚀、延长设备使用寿命。

- 通信:绝缘、无磁性,提高通信设备安全性。

- 船舶制造:耐酸、耐碱、耐腐蚀,延长设备使用寿命。

其他应用包括:

- 高磨损环境下的精密轴。

- 滚子和滚珠轴承提高性能。

- 耐磨衬里保护设备。

- 耐高温、电绝缘和耐腐蚀的半导体部件。

- 机械部件相比传统材料具有优势。

- 耐高温高压电绝缘体。

- 具有绝缘和耐温性能的电线和电线导管。

- 机械密封有效密封并防止泄漏。

- 航空航天、汽车、电子、半导体制造、化工加工和高温设备中的专业应用。

细节与零件

技术规格

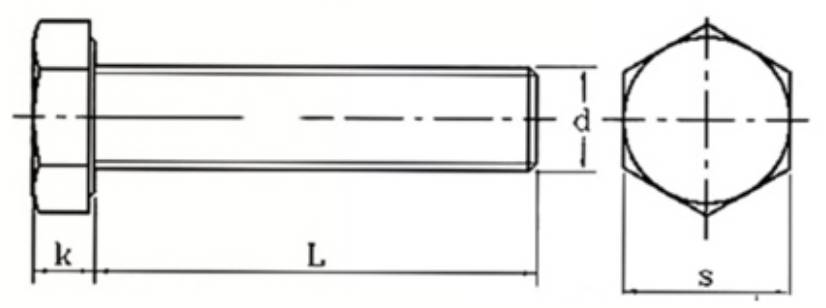

计量单位:L*K*Smm K:头部厚度;L:螺纹长度;S:对边长度;D:螺纹直径/规格。

| M16 | 外六角 | 100*9.2*24.2 | 7.*9.2*24.2 | 40*9.2*24.2 | |

| M14 | 外六角 | 80*10*22 | 50*7.6*21.9 | 40*9.9*21 | |

| M12 | 外六角 | 75*8.1*18.8 | 50*10.3*18.3 | 25*10.3*18.4 | 15*10*21.2 |

| 内六角 | 50*10.5*17.2 | 35/25*10.4*17.1 | 15*12.2*18.1 | 14*12.2*18 | |

| M10 | 外六角 | 70*7*16.8 | 35*6.6*16.6 | ||

| 内六角 | 50*9*14.8 | 35*9.1*14.8 | |||

| M8 | 内六角 | 70*5.6*14 | 50*4.5*11.7 | 35*5.3*12.9 | 25*5.3*12.9 |

| 内六角 | 50*7.6*12.3 | 35*7.9*12.3 | |||

| 沉头内六角 | 30*-*13.8 | ||||

| "+"型 | 20*-*14.2 | ||||

| M6 | 外六角 | 55*5.2*9.7 | 40*4.3*9.6 | ||

| 内六角 | 40*5.8*9.8 | 25*5.9*10 | 15*5.9*10 | ||

| "+"型 | 40*-*12 | ||||

| 外六角“__”型 | 25*3.9*9.8 | ||||

| 圆头带孔“__”型 | 20*4.8*10 | ||||

| 内六角 | 15*-*9.8 | ||||

| M5 | 外六角 | 25*3.5*8 | 20/15*3.6*8 | 10/12*3.6*7.6 | 5*3.6*8 |

| 内六角 | 35*4.7*7.8 | 25/20*4.9*8.1 | 15/12*4.9*8.1 | 10/5*4.9*8.1 | |

| 带孔圆头"+"型 | 25*-*8.6 | 20*-*8.5 | 12*-*8.5 | ||

| 圆头内六角 | 25*2.*9.3 | 12*2.8*8.6 | |||

| 圆头“__”型 | 10*3.4*7.9 | ||||

| "+"型 | 10*-*8.9 | ||||

| 带孔圆头“__”型 | 6/15*3*10 | ||||

| M4 | 外六角 | 20*3.2*6.8 | 15*3.3*6.8 | 10*3.2*6.8 | |

| 内六角 | 25*4*7 | 20*4.1*6.9 | 15*4.1*6.8 | 10*3.2*6.8 | |

| 内六角 | 25*-*8.5 | ||||

| "+"型 | 12*-*8.4 | ||||

| 圆头“__”型 | 8*2.9*7 | 5*2.1*9.3 | |||

| 带孔圆头"+"型 | 3*4.5*8.9 | ||||

| M3.5 | "+"型 | 9*-*5.3 | |||

| M3 | 外六角 | 10*3*5.5 | 30*3*5.4 | ||

| 内六角 | 30*3*5.4 | 20/25*3*5.4 | 15/10*3*5.4 | 8*3*5.4 | |

| "+"型 | 15*-*5.2 | 6*-*5.6 | |||

| 圆头"+"型 | 6.5*2.7*5.5 | ||||

| M2.5 | "+"型 | 9*-*4.5 | 6*-*3.9 | ||

| M2 | 沉头带孔“__”型半牙 | 22*1.4*3.8 | |||

| 内六角 | 14*1.9*3.8 | ||||

| 沉头“__”型 | 10*1.4*3.8 | ||||

| "+"螺纹 | 8*1.6*3.5 | ||||

| 圆头"+"型 | 8*1.5*3.5 | ||||

| 外六角 | 6*1.6*3.8 | ||||

| "+"型 | 6*-*4.2 |

我们展示的产品有不同尺寸可供选择,也可根据要求定制尺寸。

优点

- 良好的绝缘性能,耐高温。

- 高强度。

- 高硬度和耐磨性。

- 低至中等腐蚀性。

- 低腐蚀性,耐高温。

- 优异的电绝缘性。

- 化学稳定性和耐腐蚀性。

- 满足多样化的技术要求。

行业领军企业信赖之选

FAQ

什么是先进陶瓷?

精细陶瓷的主要用途有哪些?

什么是工程陶瓷?

先进陶瓷的主要类型有哪些?

精密陶瓷的主要类型有哪些?

工程陶瓷的主要类型有哪些?

先进陶瓷的应用领域有哪些?

精密陶瓷的原理是什么?

工程陶瓷有哪些应用?

如何制造先进陶瓷?

使用精密陶瓷有哪些优势?

工程陶瓷与传统陶瓷有何不同?

使用先进陶瓷有哪些优势?

使用氧化铝陶瓷有哪些优势?

氧化铝陶瓷和氧化锆陶瓷有什么区别?

为什么在某些应用中首选氧化锆陶瓷?

碳化硅陶瓷为何用于高温应用?

碳化硅陶瓷为何适合高温应用?

氮化硼陶瓷有何独特之处?

氮化硼陶瓷如何用于电子产品?

先进陶瓷如何提高能源效率?

工程陶瓷的制造工艺是什么?

工程陶瓷能否针对特定应用进行定制?

4.9 / 5

I am impressed by their extreme wear and abrasion resistance, making them perfect for high-temperature applications.

4.8 / 5

I'm pleased with the low corrosion and high-temperature resistance, ensuring long-lasting performance.

4.7 / 5

The delivery was incredibly fast! I received my order within just a few days, which is very impressive.

4.9 / 5

These alumina ceramic screws are worth every penny! They are incredibly durable and have exceeded my expectations.

4.6 / 5

The quality of these screws is top-notch, and they have significantly improved the performance of my equipment.

4.8 / 5

I'm amazed by the technological advancements in these screws. They are truly innovative and have solved many challenges I faced with traditional screws.

4.7 / 5

The Alumina Ceramic Screws are a lifesaver for my high-temperature applications. They are reliable and have never failed me.

4.9 / 5

I'm blown away by the durability of these screws. I've been using them for months now, and they still look brand new.

4.6 / 5

I highly recommend these screws for anyone working with high temperatures. They are a game-changer!

4.8 / 5

The alumina ceramic screws arrived in perfect condition and were exactly as described. Very satisfied with the purchase.

4.7 / 5

The screws are incredibly versatile and have found applications in various projects. Highly impressed with their adaptability.

4.9 / 5

I've been using these Alumina Ceramic Screws for a while now, and they continue to perform exceptionally well. Highly recommended!

4.6 / 5

The screws are easy to install and maintain, saving me valuable time and effort. I'm very pleased with this product.

4.8 / 5

I'm thrilled with the Alumina Ceramic Screws. They offer superior performance and have greatly enhanced the efficiency of my operations.

获取报价

我们的专业团队将在一个工作日内回复您。请随时与我们联系!

相关产品

弧形氧化铝陶瓷坩埚 高温耐受工程先进陶瓷

在科学探索和工业生产的征程中,每一个细节都至关重要。我们的弧形氧化铝陶瓷坩埚,凭借其出色的耐高温性和稳定的化学性质,已成为实验室和工业领域的得力助手。它们采用高纯度氧化铝材料制成,并经过精密工艺制造,确保在极端环境下也能有卓越的表现。

先进工程陶瓷低温氧化铝造粒粉

低温氧化铝造粒粉是一种通过特殊低温工艺生产的氧化铝颗粒,旨在满足对温度敏感的应用需求。该材料具有优异的低温性能和良好的加工特性,适用于多种需要低温加工和处理的行业。

工程高级陶瓷镊子带尖头弯头氧化锆陶瓷尖端

氧化锆陶瓷镊子是一种采用先进陶瓷材料制成的高精度工具,特别适用于需要高精度和耐腐蚀性的操作环境。这类镊子不仅具有优异的物理性能,而且因其生物相容性而在医疗和实验室领域广受欢迎。

相关文章

高级氧化铝陶瓷:应用与制造技术

本文讨论了先进氧化铝陶瓷的应用和制造技术,包括模具、等静压和绿色坯体。

高级氧化铝陶瓷:应用与制造技术

氧化铝陶瓷的应用和制造方法概述,包括模具、等静压和绿色体成型。

氧化锆陶瓷材料的全面概述

详细介绍氧化锆陶瓷,包括特性、历史、制备、成型、烧结和应用。

高温工程陶瓷的结构与性能

探索高温工程陶瓷在各行各业的应用、结构特点和性能优势。

目前最热门的 5 种先进陶瓷粉!

概述五大先进陶瓷粉:高纯氧化铝、波美度石、氮化铝、氮化硅和球形氧化铝,重点介绍其应用和市场趋势。

氧化锆陶瓷在牙科修复中的应用研究

探讨氧化锆陶瓷在牙科修复中的特性、制备方法和优势。

工程陶瓷材料:航空航天、电子信息、新能源和环境保护领域的应用

本文探讨了工程陶瓷材料在航空航天、电子信息、新能源和环境保护等领域的各种应用。

先进陶瓷的发展和战略重要性

深入分析先进陶瓷在各个工业和技术领域的发展、分类和战略重要性。

用于能源转换应用的精密陶瓷材料

概述能源转换技术中使用的各种陶瓷材料,包括加热器、压电陶瓷和固体氧化物燃料电池。

工程陶瓷材料的发展

探讨具有特殊性能的新型工程陶瓷及其在恶劣环境中的应用,并将其与传统材料进行比较。

陶瓷的机械性能和结构增强

深入分析陶瓷的机械性能,包括优点、缺点和改进方法。

为真空炉选择加热元件

关于选择加热元件和隔热屏以实现真空炉高效运行的指南。