新型工程陶瓷简介

特性和应用

新型工程陶瓷具有优异的耐高温、耐磨损、耐腐蚀、耐侵蚀和耐氧化性能。这些材料具有很高的弹性模量,即使在高温下也能保持很高的强度。这一系列特性使它们在传统金属材料和有机聚合物难以胜任的环境中发挥着不可或缺的作用。

| 特性 | 描述 |

|---|---|

| 耐高温 | 可承受极端温度而不降解。 |

| 耐磨损 | 可长期抵抗磨损和机械磨损。 |

| 耐腐蚀 | 不受腐蚀性物质的化学侵蚀。 |

| 抗腐蚀 | 防止材料因流体或气体流动而被物理剥离。 |

| 抗氧化性 | 防止氧化,在氧化条件下保持结构完整性。 |

这些陶瓷在推进新技术,尤其是航空航天、汽车和工业制造等领域的新技术方面发挥着关键作用。例如,在航空航天领域,它们被用于涡轮叶片和发动机部件,这些部件的高温强度和抗氧化性至关重要。在汽车领域,它们利用其耐磨性和耐腐蚀性提高了制动器和发动机部件的性能。

此外,它们的高弹性模量确保了这些材料能够承受巨大的机械应力而不变形,使其成为要求精确度和耐用性的应用的理想材料。这种多功能性使工程陶瓷成为开发新一代技术的基石,实现了以前传统材料无法实现的创新。

与金属材料的比较

工程陶瓷材料是传统金属材料的有力替代品,尤其是在要求苛刻的工业应用领域。陶瓷最显著的优势之一是 耐高温 在金属通常会软化或变形的温度下,陶瓷仍能保持结构完整性和机械性能。因此,陶瓷非常适合用于高温环境,如熔炉、发动机和燃气轮机。

在 耐腐蚀性 陶瓷的耐腐蚀性优于许多金属合金,尤其是在恶劣的化学环境中。例如,不锈钢在酸性条件下可能会腐蚀,而陶瓷(如 氧化铝陶瓷 和 碳化硅陶瓷 却不受影响。这种特性在化学加工中尤为重要,因为在化学加工中,材料会同时暴露在腐蚀性化学物质和高温下。

高硬度 高硬度 陶瓷的高硬度是另一个关键优势。氮化硅和氧化锆等陶瓷的硬度可与淬火钢媲美,甚至超过淬火钢,因此具有很强的抗磨损和耐磨性。这使它们适合应用于切削工具、轴承和其他需要在重机械应力下经久耐用的部件。

此外,陶瓷还具有 高弹性模量 这意味着它们能够抵抗负载下的变形。这一特性对于刚度和尺寸稳定性要求极高的应用领域至关重要,例如航空航天部件和精密机械。

耐磨性 是陶瓷的另一个优势领域。陶瓷能够长期承受摩擦和侵蚀而不会明显退化,因此非常适合用于齿轮和密封件等需要持续运动和接触的机械零件。

陶瓷还具有卓越的 抗热震性 这意味着它们可以承受急剧的温度变化,而不会开裂或失效。这一点在喷气发动机隔热涂层等应用中尤为重要,因为在这些应用中,温度骤然波动是很常见的。

最后,陶瓷还具有 不氧化 特性确保了陶瓷在高温下接触氧气时不会发生腐蚀或降解,而不像许多金属合金会形成氧化物和水垢。这使得陶瓷成为高温、氧化环境中的首选。

鉴于这些优势,工程陶瓷材料在各种应用中正逐渐取代昂贵的超高合金钢。它们在极端条件下的优越性能不仅提高了部件的效率和使用寿命,还减少了维护成本和停机时间。

工程陶瓷的类型

氧化物陶瓷材料

氧化物陶瓷包含多种材料,包括 氧化铝 氧化镁、氧化铍、氧化锆、氧化锡、二氧化硅和莫来石陶瓷。这些材料因其卓越的化学稳定性(尤其是在高温条件下)和出色的抗氧化性而闻名于世。

与非氧化物陶瓷相比,氧化物陶瓷通常具有更高的化学稳定性和更强的抗环境降解能力。因此,氧化物陶瓷特别适用于不可避免地暴露在极端温度和腐蚀性环境中的应用。例如 氧化铝 由于具有高介电强度和热稳定性,被广泛用于高温熔炉和电气应用中的绝缘体。

此外,氧化物陶瓷的生产过程通常涉及高温烧结,因此可以精确控制材料的微观结构。这种控制可确保最终产品满足从高性能切削工具到先进结构部件等各种工业应用的严格要求。

下表简要介绍了一些常见的氧化物陶瓷及其主要特性:

| 陶瓷材料 | 主要特性 | 应用 |

|---|---|---|

| 氧化铝 (Al₂O₃) | 高硬度、热稳定性 | 切削工具、炉衬 |

| 氧化镁 | 优异的导热性 | 电绝缘体、耐火材料 |

| 氧化锆 | 高韧性、耐腐蚀性 | 医疗植入物、切割工具 |

| 二氧化硅 | 热膨胀率低、熔点高 | 玻璃、光纤 |

| 莫来石 | 高抗热震性 | 耐火衬里、熔炉部件 |

这些特性使氧化物陶瓷成为对可靠性和耐用性要求极高的行业不可或缺的材料,尤其是在恶劣的工作环境中。

非氧化物陶瓷材料

非氧化物陶瓷材料种类繁多,包括氮化物、碳化物、硅化物和硼化物。其中包括 氮化硅 (Si₃N₄) , 碳化硅(SiC) 和 氮化硼 (BN) 因其优异的热性能而脱颖而出。这些材料因其 高导热性 这使它们能够有效地散热,而且它们的 热膨胀率低 从而最大限度地减少热应力和变形。此外,它们还表现出 优异的抗热震性 使其非常适合应用于温度急剧变化的环境中。

| 材料 | 导热系数(瓦/米-千克) | 热膨胀系数(10-⁶/-K) | 抗热震性 |

|---|---|---|---|

| 氮化硅 | 20-170 | 2.7-3.2 | 高 |

| 碳化硅 | 120-270 | 4.0-4.5 | 极高 |

| 氮化硼 | 30-500 | 4.5-5.5 | 高 |

这些非氧化物陶瓷的优异热性能归功于其原子结构,这种结构可促进有效的声子传输并最大限度地降低热膨胀。这一系列特性使它们在高温应用领域(如对耐用性和可靠性要求极高的航空航天、汽车和工业机械领域)具有极高的价值。

多孔陶瓷材料的应用

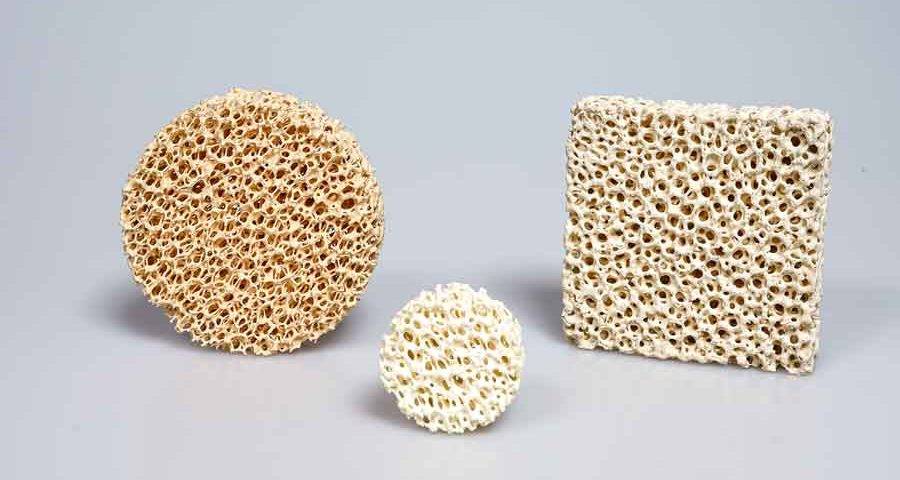

泡沫陶瓷过滤器

多孔陶瓷以其复杂的结构和广泛的应用而闻名,在现代工业流程中发挥着举足轻重的作用。这些材料具有高孔隙率,可提高过滤、分离和扩散等关键领域的性能。多孔陶瓷的独特性能,包括热稳定性和化学惰性,使其在传统材料难以胜任的环境中不可或缺。

多孔陶瓷最重要的应用之一是金属净化,可用作泡沫陶瓷过滤器。这些过滤器旨在去除熔融金属中的杂质和夹杂物,从而提高最终产品的整体质量和性能。由于需要更高的材料纯度和更强的机械性能,泡沫陶瓷过滤器在金属提纯工艺中的使用呈上升趋势。

| 应用 | 优点 |

|---|---|

| 过滤 | 有效去除熔融金属中的杂质和夹杂物 |

| 分离 | 有效分离工业流程中的不同物相 |

| 填充 | 在高温环境中提供结构支撑和隔热性能 |

| 扩散 | 促进受控气体或液体扩散,提高反应速率 |

| 催化剂 | 支持催化反应,提高效率和选择性 |

| 生物酶载体 | 提高酶的活性和稳定性,这在生物技术应用中至关重要 |

泡沫陶瓷过滤器在金属净化领域的应用日益广泛,这证明了其在提高材料性能方面的功效。通过确保去除有害杂质,这些过滤器有助于生产出机械性能更优越、更耐用、抗环境应力能力更强的金属。随着各行各业不断挑战材料性能的极限,泡沫陶瓷过滤器在金属净化方面的作用将变得更加重要。

切削工具材料的开发

高速钢

高速钢(HSS)是制造各种复杂工具的通用材料,能够加工从有色金属到高温合金等各种材料。这类钢又分为三种主要类型:通用高速钢、高性能高速钢和粉末冶金高速钢。

- 通用高速钢:这种钢最常用,因为它兼顾了硬度和韧性,适用于各种切削应用。

- 高性能高速钢:这种钢专为要求更高的任务而设计,具有更强的耐磨性和红色硬度,可在高温下保持切削性能。

- 粉末冶金高速钢:这种钢采用先进的粉末冶金技术,具有优异的均匀性和更细的碳化物分布,与传统的高速钢相比,韧性和耐磨性更强。

高速钢在各种加工环境中的适应性使其成为切削工具材料发展的基石,与陶瓷和超硬材料的进步相辅相成。

硬质合金

硬质合金是一种通过粉末冶金技术制造的尖端材料,它将难熔金属碳化物与金属粘结剂结合在一起。这种独特的成分赋予了硬质合金显著超越高速钢的优异性能。在常温下,硬质合金具有无与伦比的硬度和切削速度,是高性能加工应用中不可或缺的材料。

最常见的硬质合金包括基于钨和钴的硬质合金,以及钨、钛和钴硬质合金。每种不同的硬质合金都具有独特的优势,可满足特定的工业需求。例如,碳化钨-钴(WC-Co)合金以其高韧性和耐磨性而闻名,而基于碳化钛的合金则具有卓越的硬度和热稳定性。

| 类型 | 主要特性 | 应用 |

|---|---|---|

| 碳化钨-钴 (WC-Co) | 高韧性、耐磨性 | 采矿工具、金属切削、冲压模具 |

| 碳化钨-钛(WC-TiC-Co) | 高硬度、热稳定性 | 高速加工、切削工具 |

| 碳化钨-钛-钽(WC-TiC-TaC-Co) | 平衡硬度和韧性 | 航空航天部件、高精度加工 |

硬质合金的卓越性能不仅限于其机械性能。它能够在高温和磨损环境等极端条件下保持完整性,是汽车和航空航天等行业的关键材料。这种多功能性确保了硬质合金继续成为开发尖端技术的基石。

陶瓷切削刀具

陶瓷切削刀具以其优异的硬度和耐磨性脱颖而出,使其切削速度远远高于硬质合金刀具。具体来说,陶瓷刀具的切削速度是硬质合金刀具的三到十倍,因此在高速加工操作中不可或缺。

在高速切削应用中,陶瓷刀具能在高温下保持锋利和结构完整性,这对实现精确切削和延长刀具寿命至关重要。此外,陶瓷刀具超强的耐磨性确保其能够承受硬切削时遇到的磨擦力,进一步提高了刀具的耐用性和有效性。

陶瓷刀具也越来越受干式切削工艺的青睐,在干式切削工艺中,由于没有冷却剂或润滑剂,因此需要在干燥条件下性能可靠的材料。陶瓷刀具能够切削淬硬钢和复合材料等难加工材料,这凸显了陶瓷刀具在具有挑战性的加工环境中的多功能性和坚固性。

| 特点 | 陶瓷刀具 | 硬质合金刀具 |

|---|---|---|

| 切削速度 | 高 3-10 倍 | 标准 |

| 硬度 | 极高 | 高 |

| 耐磨性 | 优 | 良好 |

| 应用 | 高速、干硬、难加工材料 | 各种加工操作 |

陶瓷切削工具在这些苛刻环境中的卓越性能,使其在需要高效、高精度加工的各行各业得到广泛应用。

超硬切削工具材料

超硬切削工具材料,如金刚石和立方氮化硼(CBN),因其卓越的性能正在彻底改变加工行业。这些材料具有无与伦比的高温硬度、耐磨性和热化学稳定性,是切割和加工高硬度材料不可或缺的材料。

这些超硬材料的主要优势之一是即使在高温下也能保持高硬度。这对于传统材料会迅速降解的高速加工操作至关重要。例如,以硬度极高著称的金刚石,即使在高速切削过程中产生的高温下也能保持高效。同样,CBN 具有高导热性和化学惰性,可确保切削工具在苛刻的环境中保持锋利和功能性。

除了热性能外,超硬材料还具有显著的耐磨性。这一特性在刀具需要持续承受高应力的行业中尤为重要。耐磨损和抗崩角的能力大大延长了切削工具的使用寿命,减少了维护成本和停机时间。

此外,这些材料的热化学稳定性可确保它们不会与被加工材料发生反应,从而防止形成有害化合物,损害刀具和工件的完整性。在加工钛合金或硬化钢等活性材料时,这种稳定性尤为有利。

总之,将超硬切削刀具材料融入现代加工工艺是该领域的一大进步。它们将高温硬度、耐磨性和热化学稳定性独特地结合在一起,是完成最具挑战性的加工任务的首选。

涂层工具

涂层刀具是切削刀具技术的一大进步,它是通过在硬质合金或高速钢基体上涂覆一层或多层具有优异耐磨性的耐火化合物而实现的。这些涂层通常由氮化钛 (TiN)、碳化钛 (TiC) 或氧化铝 (Al₂O₃)等材料制成,可在几个关键方面提高底层刀具材料的性能。

首先,添加这些涂层可显著提高加工效率。涂层的耐磨性增强后,切削速度加快,刀具磨损减少,从而提高了加工过程的整体生产率。这对于刀具处于极端条件下的高速加工操作尤为有利。

其次,涂层刀具有助于提高加工精度。保护层可最大限度地减少刀具变形和磨损,从而降低加工零件出现尺寸误差的可能性。在航空航天和汽车制造等必须严格控制公差水平的行业中,这种精度至关重要。

此外,延长涂层工具的使用寿命也是另一个显著优势。涂层中使用的耐火化合物可承受高温和恶劣的切削条件,从而延长了刀具的使用寿命,减少了更换次数。这种使用寿命不仅减少了停机时间,还降低了工具的总体成本。

最后,使用涂层刀具的经济效益也非常可观。通过延长刀具寿命和提高加工效率,这些涂层刀具有助于降低加工操作的总成本。这种成本效益使涂层刀具成为希望优化生产流程的制造商的一个极具吸引力的选择。

总之,涂层刀具改变了切削刀具技术领域的游戏规则,它融合了更高的性能、精度、寿命和成本效益,是非涂层刀具无法比拟的。

相关产品

- 精密加工用CVD金刚石刀具毛坯

- 工程先进陶瓷氧化铝Al2O3陶瓷垫圈,用于耐磨应用

- 定制氮化硼(BN)陶瓷件

- 工程用高级精密陶瓷高温氧化铝(Al2O3)保护管

- 弧形氧化铝陶瓷坩埚 高温耐受工程先进陶瓷