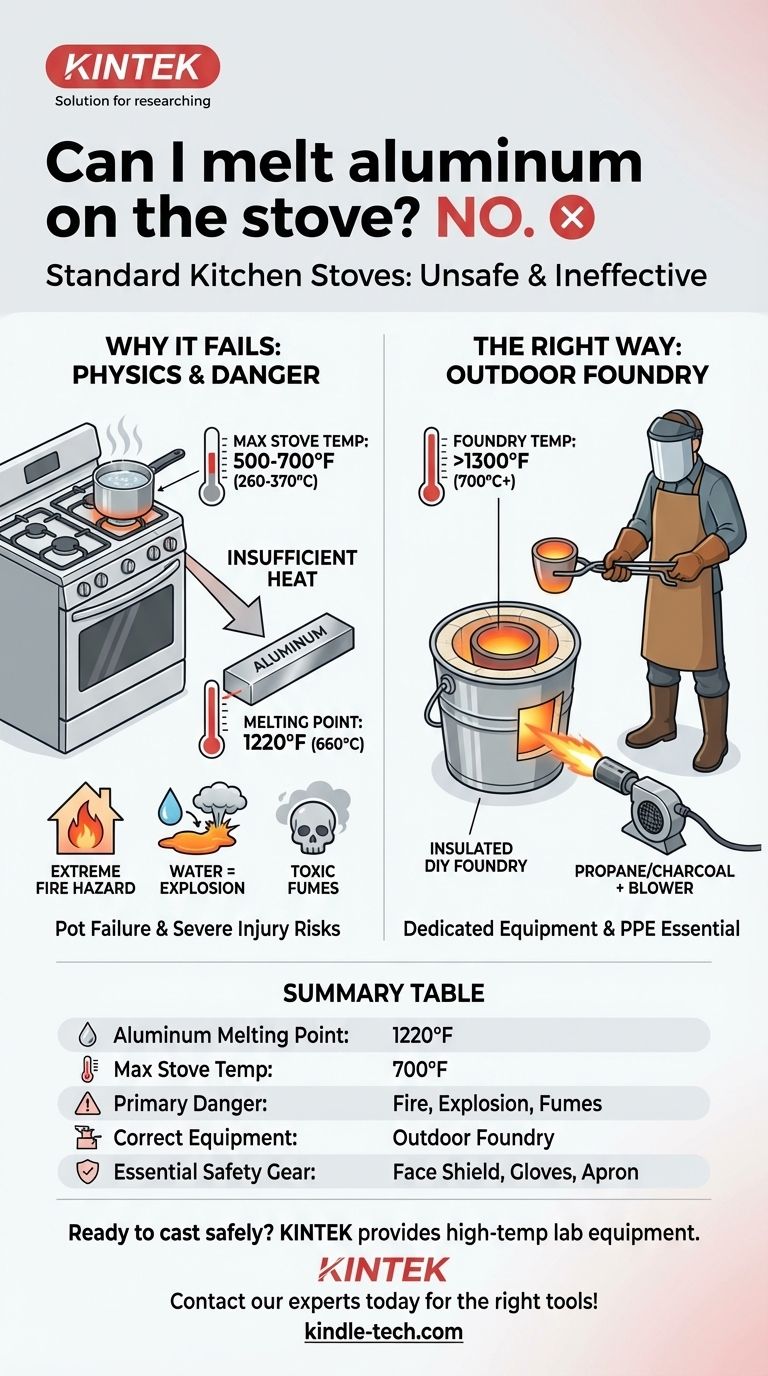

不,您不能在标准的厨房炉灶上安全或有效地熔化铝。 虽然这看起来像是一项简单的任务,但家用炉灶无法满足熔化金属所需的基本温度要求,并且尝试这样做会带来极高的火灾、有毒烟雾和严重伤害的风险。

核心问题有两个:厨房炉灶根本无法产生熔化铝所需的持续高温 1220°F (660°C),而尝试这样做会带来不可接受的火灾、有毒烟雾和严重伤害的风险。

为什么您的厨房炉灶达不到要求

尝试在炉灶上熔化铝不是耐心的问题;而是物理学的问题。该设备在根本上不适合这项任务。

关键的温度屏障

铝的熔点约为 1220°F 或 660°C。这是一个固定的物理特性。

标准的厨房炉灶,无论是燃气还是电动的,都是为烹饪设计的,烹饪的温度要低得多。

炉灶的最高温度

电炉盘或玻璃灶台的温度可能达到 500-700°F (260-370°C)。燃气火焰在其源头更热,但实际传递到锅中的热量是为烹饪调节的,而不是冶金。

简而言之,您的炉灶的正常运行的任何部分都不是为了达到并维持将固体铝变成液态所需的温度而设计的。

热量传递的问题

即使燃气火焰的一小部分在技术上可以达到所需温度,但炉灶的设计也不是为了有效地将热量传递给金属块。

炉灶加热锅底。而专业的熔炉或铸造厂的设计是从各个方向包围金属,确保均匀而高效的熔化。

尝试的不可接受的危险

除了它行不通这个简单的事实之外,在厨房里尝试熔化铝是非常危险的。这种环境完全不适合处理熔融金属。

极端的火灾危险

您的厨房里充满了易燃材料,从食用油和油脂残留物到木制橱柜和纸巾。将明火源长时间保持在其绝对最大功率,会带来重大且失控的火灾风险。

熔融金属和水不相容

厨房是富含水的环境。即使一滴水接触到熔融的铝,它也会瞬间闪蒸成蒸汽,体积膨胀超过其原始体积的 1500 倍。

这会导致剧烈的爆炸,可能将熔融金属喷洒到大片区域,从而引发灾难性的火灾和危及生命的烧伤。

有毒烟雾吸入

您可能想要熔化的绝大多数铝,例如苏打罐或废料,都不是纯净的。它们表面涂有油漆、塑料和其他化学物质。

加热这些材料会释放出 有毒和致癌的烟雾。您厨房的通风罩不具备处理此类化学废气的能力,会使您和您的家人暴露在有害空气中。

设备灾难性故障

厨房锅不是 坩埚。坩埚是专门设计用于承受极端热应力和容纳熔融金属的陶瓷或金属容器。

钢锅或铝锅很可能会失效,要么自身熔化,要么因强烈的、集中的热量而破裂,从而洒出熔融金属并引发火灾。

完成工作的正确工具

熔化金属是一项可以实现的爱好,但它需要专用的设备和对安全的承诺。这意味着需要将操作从厨房转移到通风良好的室外空间。

建造一个DIY铸造厂

只需花费几美元,您就可以建造一个小型、有效的熔化铝的铸造厂。这些通常被称为“桶式”或“咖啡罐”熔炉。

关键部件是钢容器、耐火衬里(通常是熟石膏和沙子的混合物)以保持热量,以及一个盖子。

强大的热源

您的铸造厂需要比炉灶更强大的燃料。初学者最常见的两种选择是 木炭 或 丙烷。

这种燃料与鼓风机(通常是吹风机)产生的强力空气结合使用,可显著提高铸造厂内部的温度,轻松超过铝的熔点。

必要的安全装备 (PPE)

处理熔融金属需要 个人防护装备 (PPE)。这不是可有可无的。

最低限度,您需要一个全面罩、厚皮革焊接手套、一个皮围裙和封闭式鞋子(最好是皮制的)。合成衣物可能会熔化并粘在皮肤上,因此绝对不应穿着。

安全地开始金属铸造

了解正确的方法是迈向有益且安全的爱好的第一步。

- 如果您的主要关注点是好奇心: 请了解熔化铝是一项需要专用工具的任务,而厨房炉灶在根本上不安全,也不适合这项工作。

- 如果您的主要关注点是开展一项新爱好: 您的第一步应该是研究 DIY 铸造厂设计并在您接触任何金属之前获取必要的个人防护装备。

- 如果您的主要关注点是特定的项目: 优先建立一个安全的室外设置。花时间建造一个合适的铸造厂是对防止火灾或严重伤害的一小笔投资。

以对热量的尊重和对安全的关注来对待金属加工是实现想法的关键。

摘要表:

| 要点 | 细节 |

|---|---|

| 铝熔点 | 1220°F (660°C) |

| 炉灶最高温度 | ~500-700°F (260-370°C) |

| 主要危险 | 火灾、有毒烟雾、蒸汽爆炸 |

| 正确的设备 | 带丙烷/木炭的室外铸造厂 |

| 必需的安全装备 | 面罩、皮革手套、围裙 |

准备好安全有效地开始您的金属铸造项目了吗?

不要用不合适的设备来冒险您的安全。KINTEK 专注于高温实验室和车间设备,包括专为冶金设计的坩埚和安全装备。我们的产品帮助业余爱好者和专业人士在没有厨房设置危险的情况下实现精确、受控的熔化。

立即联系我们的专家,找到满足您需求的正确工具,自信地进行铸造!

图解指南