为什么选择我们

简易的订购流程、优质的产品和专业的支持,助力您的业务成功。

应用

碳化硅(SiC)陶瓷片是环保材料,主要用于 LED 照明和电子行业。它们为电子和光电领域的传热和散热提供了高效的解决方案。这些陶瓷片在绝缘性能和高导热性方面表现出色,可防止泄漏和击穿,同时确保电气安全和有效的热传递。其高红外辐射率可实现高效散热,而其低膨胀系数则可最大限度地减少热应力和机械故障的风险。

- IC、芯片组、CPU、MOS:碳化硅陶瓷片适用于各种集成电路和电子元件的散热。

- LED 照明散热器:用于 LED 照明产品的散热,以确保 LED 的最佳性能并延长 LED 的使用寿命。

- 超薄液晶电视和机顶盒:这些陶瓷片用于超薄液晶电视和机顶盒的热管理。

- 网络设备:应用于接入点、路由器、ADSL 调制解调器和网络交换机,以确保高效冷却。

- 信息技术:碳化硅陶瓷片用于主板、笔记本电脑、显卡和内存模块,以有效散热。

- 电源:用于电源模块和功率晶体管,以维持适当的工作温度并提高性能。

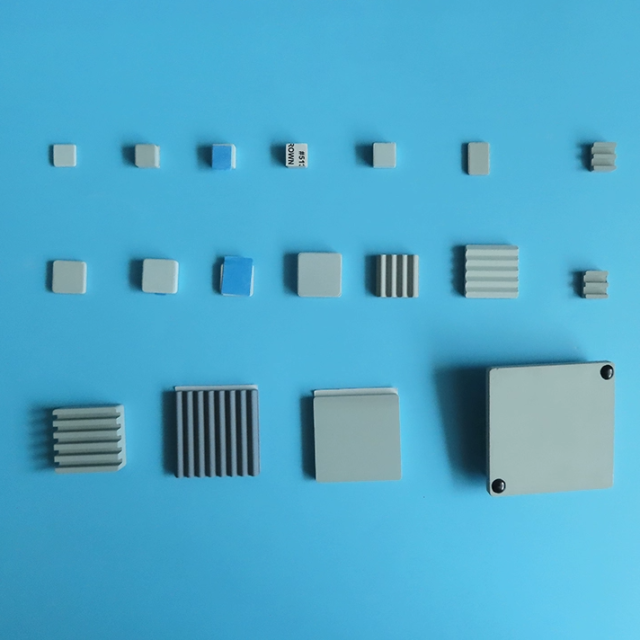

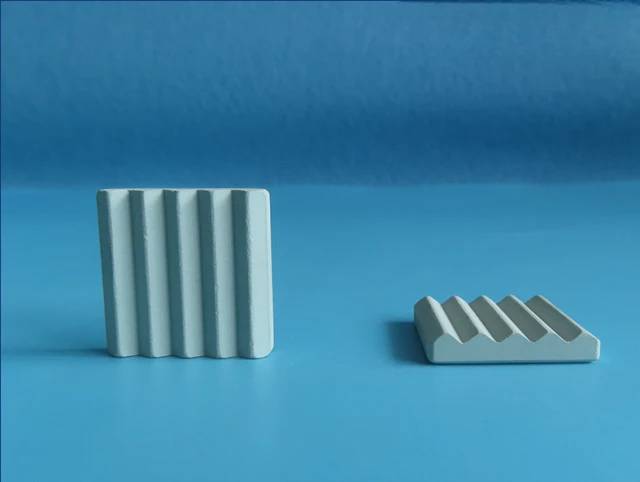

细节与部件

技术规格

| 25*25*3mm | 30*30*5mm | 40*404mm | 50*50*5mm |

| 25*25*5mm | 30*30*5mm | 40*40*5mm | 60*60*5mm |

| 25*25*5mm | 30*30*8mm | 40*40*5mm | 60*60*8mm |

| 25*25*8mm | 30*30*10mm | 40*40*7mm | |

| 25*25*10mm | 35*35*10mm | 40*40*8mm | |

| 30*30*2.5mm | 40*40*3mm | 50*50*5mm |

我们展示的产品有不同尺寸可供选择,也可根据要求定制尺寸。

优点

- 环保:碳化硅陶瓷片采用绿色环保材料制成,符合 ROHS 环保要求。

- 高效散热:与铜和铝相比,它们具有卓越的散热性能,可确保电子产品的寿命和可靠性。

- 紧凑轻便:这些陶瓷芯片尺寸小、重量轻,可实现高效的产品设计和布局。

- 抗干扰和抗静电:具有优良的电气性能,包括绝缘、耐高温、耐氧化、耐酸碱,并具有有效的抗干扰和抗静电作用。

行业领军企业信赖之选

FAQ

精细陶瓷的主要用途有哪些?

精密陶瓷的主要类型有哪些?

精密陶瓷的原理是什么?

使用精密陶瓷有哪些优势?

4.8 / 5

Fast delivery and excellent packaging, the quality of the product is superb, will definitely order again.

5.0 / 5

Amazing product! It perfectly fits my needs and exceeded my expectations. Highly recommended!

4.7 / 5

Great value for money. The product is well-designed and durable, worth every penny.

4.9 / 5

Top-notch quality and craftsmanship. I'm impressed with its performance and durability.

5.0 / 5

Cutting-edge technology that outperforms other products in the market. Simply outstanding!

4.8 / 5

The product is a testament to innovation and quality. Highly satisfied with my purchase.

4.9 / 5

Excellent product that meets all my requirements. I highly recommend it to anyone looking for a reliable solution.

5.0 / 5

Exceptional product that delivers exceptional results. I'm thrilled with my purchase.

4.8 / 5

Outstanding product with remarkable features. I'm thoroughly impressed with its performance.

4.9 / 5

Game-changing product that revolutionizes the industry. I'm amazed by its capabilities.

5.0 / 5

Unparalleled product that sets a new standard for quality and innovation. Highly recommended!

4.7 / 5

Impressive product that combines functionality and aesthetics seamlessly. I'm delighted with my purchase.

4.8 / 5

Revolutionary product that changes the way I work. I'm grateful for its efficiency and reliability.

获取报价

我们的专业团队将在一个工作日内回复您。请随时与我们联系!

相关产品

弧形氧化铝陶瓷坩埚 高温耐受工程先进陶瓷

在科学探索和工业生产的征程中,每一个细节都至关重要。我们的弧形氧化铝陶瓷坩埚,凭借其出色的耐高温性和稳定的化学性质,已成为实验室和工业领域的得力助手。它们采用高纯度氧化铝材料制成,并经过精密工艺制造,确保在极端环境下也能有卓越的表现。

相关文章

安装碳化硅棒的注意事项

安装碳化硅支架的注意事项

电极夹具指南:类型、设计和应用

了解电极夹具的全面指南,涵盖各种类型、设计注意事项以及电极夹具在电镀、焊接和电化学电池等行业中不可或缺的作用。

热等静压技术为何如此有效

热等静压(HIP)是一种利用高温高压改善材料机械性能的制造工艺。该工艺包括将零件置于密封腔内,并对其施加高温和高压。

用于能源转换应用的精密陶瓷材料

概述能源转换技术中使用的各种陶瓷材料,包括加热器、压电陶瓷和固体氧化物燃料电池。

半导体应用中的精密陶瓷

探索半导体设备中精密陶瓷的使用、特性和制造工艺。

工程陶瓷材料:航空航天、电子信息、新能源和环境保护领域的应用

本文探讨了工程陶瓷材料在航空航天、电子信息、新能源和环境保护等领域的各种应用。

金属新材料推动人工智能芯片进步

探讨新型金属材料如何推动人工智能芯片升级,影响计算能力和半导体制造。

用 CVD 法制备硅碳负极材料的技术概述

本文讨论了通过 CVD 制备的硅碳负极材料的关键技术方面,重点是其合成、性能改进和工业应用潜力。

MPCVD 单晶金刚石在半导体和光学显示领域的应用

本文讨论了 MPCVD 单晶金刚石在半导体和光学显示领域的应用,重点介绍了其优越性能和对各行各业的潜在影响。

玻璃基板在先进半导体封装中的崛起

探讨先进半导体封装向玻璃基板的转变、玻璃基板的优势和挑战。

PECVD 纳米涂层技术在电子器件中的应用

PECVD 纳米涂层技术可提高各种电子设备的耐用性和可靠性。

目前最热门的 5 种先进陶瓷粉!

概述五大先进陶瓷粉:高纯氧化铝、波美度石、氮化铝、氮化硅和球形氧化铝,重点介绍其应用和市场趋势。