电气故障

温度异常

真空炉的温度异常可能表现为高温报警或系统无法达到设定温度值。这些问题会严重影响真空炉的运行和效率,导致潜在的生产延迟和维护成本增加。

要解决高温报警问题,关键是要验证恒温器的准确性和功能。这包括校准恒温器参数,以确保参数设置正确,并对温度变化做出适当响应。此外,检查固态继电器输出也至关重要。固态继电器故障会导致温度控制不稳定,从而引发错误警报。对这些部件进行定期维护和测试可以防止出现此类问题。

另一方面,如果炉子无法达到所需的温度,则应彻底检查热电偶探头。热电偶是测量炉内实际温度的关键。如果热电偶损坏或校准不当,就会导致读数不准确,从而导致温度控制失效。更换或重新校准热电偶探头可以解决这个问题,并确保精确的温度调节。

总之,要保持真空炉精确的温度控制,需要采用系统的方法来诊断和解决温度异常。通过关注恒温器参数、固态继电器输出和热电偶探头,操作员可以确保真空炉高效运行。

真空异常

窑炉中的真空异常会严重影响其性能和效率。这些问题通常表现为真空泵抽气不畅或真空度过低,从而导致加工条件不理想。要解决这些问题,需要采用系统的方法来识别和纠正根本原因。

排除真空异常的第一步是检查气源。确保气源清洁且无污染物可防止真空系统堵塞。此外,还应检查真空规的准确性和校准情况。校准不当的真空规会误导操作员,导致错误的调整和持续的问题。

门密封的完整性是另一个关键因素。有问题的门封会使空气漏入腔室,影响真空度。定期检查和维护门封,包括检查密封胶条的状况和门板的对齐情况,是必不可少的预防措施。

最后,应检查管道系统是否有任何磨损或损坏的迹象。管道损坏或连接不良会导致漏气,从而降低整体真空效率。确保所有连接牢固,没有明显的裂缝或孔洞,有助于保持最佳真空度。

通过系统地解决气源、真空规、门密封和管道等方面的问题,操作人员可以有效地解决真空异常问题,确保真空炉顺利运行。

机械结构故障

炉门问题

在处理真空炉时,最常见的机械结构故障之一与炉门密封不严有关。这个问题会导致严重的运行效率低下和潜在的安全隐患。解决这一问题的主要方法是对几个关键部件进行彻底检查。

首先是 门铰链 应检查是否有任何磨损或不对齐的迹象。正确对齐对于确保门均匀、安全地关闭至关重要。如果铰链磨损或松动,可能需要拧紧或更换,以恢复正常功能。

下一步、 拉扣 对门的有效密封能力起着至关重要的作用。这些拉扣有助于将门固定到位,任何故障都会导致密封性变差。必须检查拉扣的功能是否正常,是否被阻塞或损坏。

密封胶带 是另一个必须检查的重要部件。随着时间的推移,密封带可能会退化或错位,从而导致泄漏。定期检查密封带的状况和对齐情况可以防止出现这种问题。如果胶带磨损或损坏,应及时更换,以确保密封性。

最后,门板 门板 本身是否有任何变形或损坏。门板上的任何异常都会影响其正常密封的能力。确保门板处于良好状态并正确对齐是保持有效密封的关键。

通过系统地检查这些部件,操作员可以处理和解决与炉门密封不严有关的问题,从而保持真空炉的效率和安全性。

风扇故障

风扇发出的奇怪声音可能是真空炉内部潜在故障的早期信号。这些声音通常被描述为磨擦声、嘎嘎声或嗡嗡声,可能源于各种问题,如果不加以控制,可能会导致更严重的运行问题。

造成这些声音的主要原因之一是风扇组件中存在异物。随着时间的推移,灰尘、金属屑或其他碎屑会积聚在风扇叶片或外壳内。这种侵入会导致风扇运转不均匀,从而产生特有的怪声。定期检查和维护,包括清除任何异物,对防止这些问题至关重要。

风扇相关噪音的另一个常见来源是电机螺丝松动。随着时间的推移,炉内的持续振动和运动会导致这些螺丝移位或松动。这种松动会在风扇旋转时发出嘎吱嘎吱的声音,表明需要立即处理。拧紧这些螺钉通常可以解决问题,但必须确保所有部件都被牢牢固定,以防今后再发生类似情况。

| 问题 | 可能原因 | 解决方法 |

|---|---|---|

| 奇怪的噪音 | 风扇中有异物 | 清除杂物并清洁组件 |

| 电机螺丝松动 | 拧紧所有螺丝并固定部件 |

及时处理这些风扇故障对于保持真空炉的效率和使用寿命至关重要。包括彻底检查和必要调整在内的定期维护计划有助于防止小问题升级为更严重的问题。

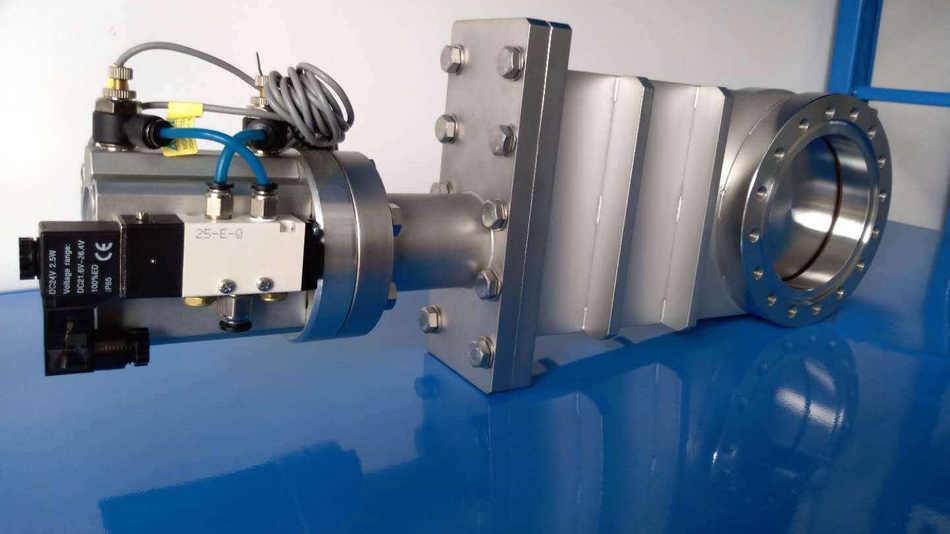

气动阀故障

真空炉中的气动阀门故障可能会扰乱运行并导致严重停机。这些故障通常表现为阀门无法按要求打开或关闭,从而影响系统维持所需真空度和工艺条件的能力。

要诊断和解决这些问题,技术人员应首先检查电磁阀。这些阀门是控制压缩空气流量的关键部件,任何故障都可能导致整个气动系统无法运行。常见问题包括电磁阀卡住或损坏,可能需要清洁、维修或更换。

此外,确保适当的压缩空气供应压力也至关重要。压力不足或过高都会导致阀门功能失常。定期检查和调整气压以及维护空气压缩机和相关管道可以防止许多常见的气动阀故障。

总之,解决气动阀故障需要系统性的方法,首先要彻底检查电磁阀,并确保压缩空气压力在规定范围内。