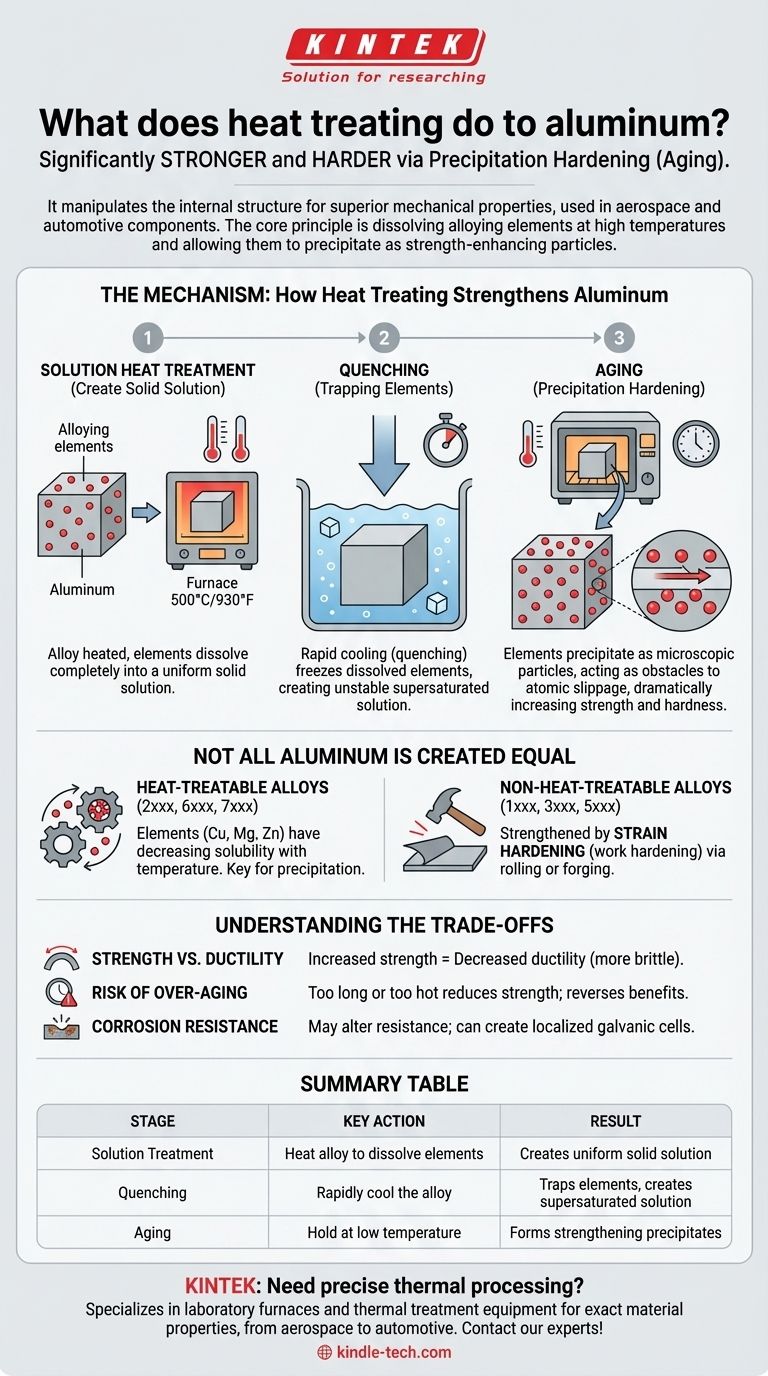

简而言之,对特定铝合金进行热处理可以显著提高其强度和硬度。 这一过程被称为沉淀硬化或时效处理,它通过调控材料的内部结构,使其获得远超铝自然状态的机械性能,从而可用于航空航天和汽车零部件等高性能应用。

热处理铝的核心原理不在于硬化铝本身,而在于在高温下将合金元素溶解到铝中,然后使其以微小的、增强强度的颗粒形式在金属结构中析出。

机理:热处理如何强化铝

要理解热处理的效果,我们首先需要了解其底层的冶金学原理。该过程是一个精心控制的三步序列,旨在在合金内部产生内部增强。

### 起点:固溶体

纯铝相对较软。为了增强其性能,会加入铜、镁或锌等元素。热处理的第一步是形成均匀的混合物。

### 步骤 1:固溶处理

将铝合金加热到高温(取决于合金,约为 500°C 或 930°F)并保持。在此温度下,合金元素完全溶解到铝中,形成均匀的固溶体,就像糖溶解在热水中一样。

### 步骤 2:淬火

然后将合金快速冷却,即淬火,通常在水中进行。温度的突然下降将溶解的合金元素“冻结”在原位,形成不稳定的过饱和溶液。原子来不及逃逸。

### 步骤 3:时效(沉淀硬化)

这是最后也是最关键的一步。淬火后的材料在室温下(自然时效)或在低温烘箱中(人工时效)进行“时效”。在此期间,被困住的合金元素开始从溶液中析出,在铝的晶体结构中形成极其微小、坚硬且均匀分布的颗粒。

这些颗粒充当微观障碍,使得金属的原子层之间更难相互滑移。这种对内部移动的抵抗力就是我们所感知的强度和硬度的显著提高。

并非所有铝都一样

至关重要的是要了解,并非所有铝合金都可以通过热处理来强化。能够进行硬化的能力完全取决于合金的化学成分。

### 可热处理合金

2xxx、6xxx 和 7xxx 系列的合金被认为是可热处理的。它们的合金化元素(如铜或镁/硅)在温度下降时在铝中的溶解度会降低,这是沉淀过程得以发挥作用的基本要求。

### 不可热处理合金

1xxx、3xxx 和 5xxx 系列的合金不能通过热处理来强化。它们是通过形变硬化(也称为加工硬化)来实现强度的,这涉及通过轧制或锻造等工艺对金属进行物理变形。

理解权衡

改变材料的性能总会涉及妥协。热处理也不例外,了解这些权衡对于正确的材料选择至关重要。

### 强度与延展性的权衡

主要的权衡在于强度和延展性之间。当您通过热处理提高合金的硬度和强度时,您通常会降低其延展性,使其更脆,对弯曲或冲击的容忍度更低。

### 过时效的风险

时效过程是时间和温度的函数。如果合金在其时效温度下保持时间过长或温度过高,细小的析出物将开始长大和粗化。这种过时效实际上会降低材料的强度和硬度,从而有效地抵消了处理带来的好处。

### 耐腐蚀性的变化

热处理有时会改变合金的耐腐蚀性。在材料晶界附近形成的析出物可能会产生局部电偶电池,可能使某些高强度合金更容易受到某些类型的腐蚀。

为您的应用做出正确的选择

选择正确的合金和热处理完全取决于您组件所需的预期结果。

- 如果您的主要关注点是最大的强度和硬度: 选择 7xxx 或 2xxx 系列合金,并应用完全的固溶处理和人工时效过程(例如 T6 状态)。

- 如果您的主要关注点是良好的成形性和中等强度: 使用处于加工硬化状态的不可热处理合金(如 5xxx 系列)或处于退火、预处理状态的可热处理合金(如 6061)。

- 如果您的主要关注点是平衡强度、成本和耐腐蚀性: 6xxx 系列合金(如 6061-T6)通常是各种结构应用中最通用和最常见的选择。

最终,热处理将某些铝合金从一种常见的轻质金属转变为高性能工程材料。

总结表:

| 热处理阶段 | 关键操作 | 结果 |

|---|---|---|

| 固溶处理 | 加热合金以溶解元素 | 形成均匀的固溶体 |

| 淬火 | 快速冷却合金 | 捕获元素,形成过饱和溶液 |

| 时效 | 在低温下保持 | 形成强化析出物 |

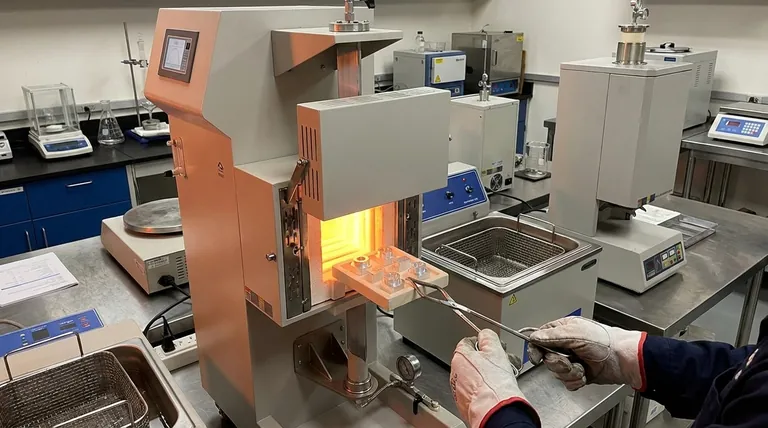

需要对您的铝部件进行精确的热加工吗? KINTEK 专注于实验室炉和热处理设备,提供实现项目所需的精确材料性能所必需的受控加热解决方案。从航空航天合金到汽车零部件,我们的专业知识确保了可靠和可重复的结果。立即联系我们的热处理专家,讨论我们如何支持您的高性能材料需求!

图解指南