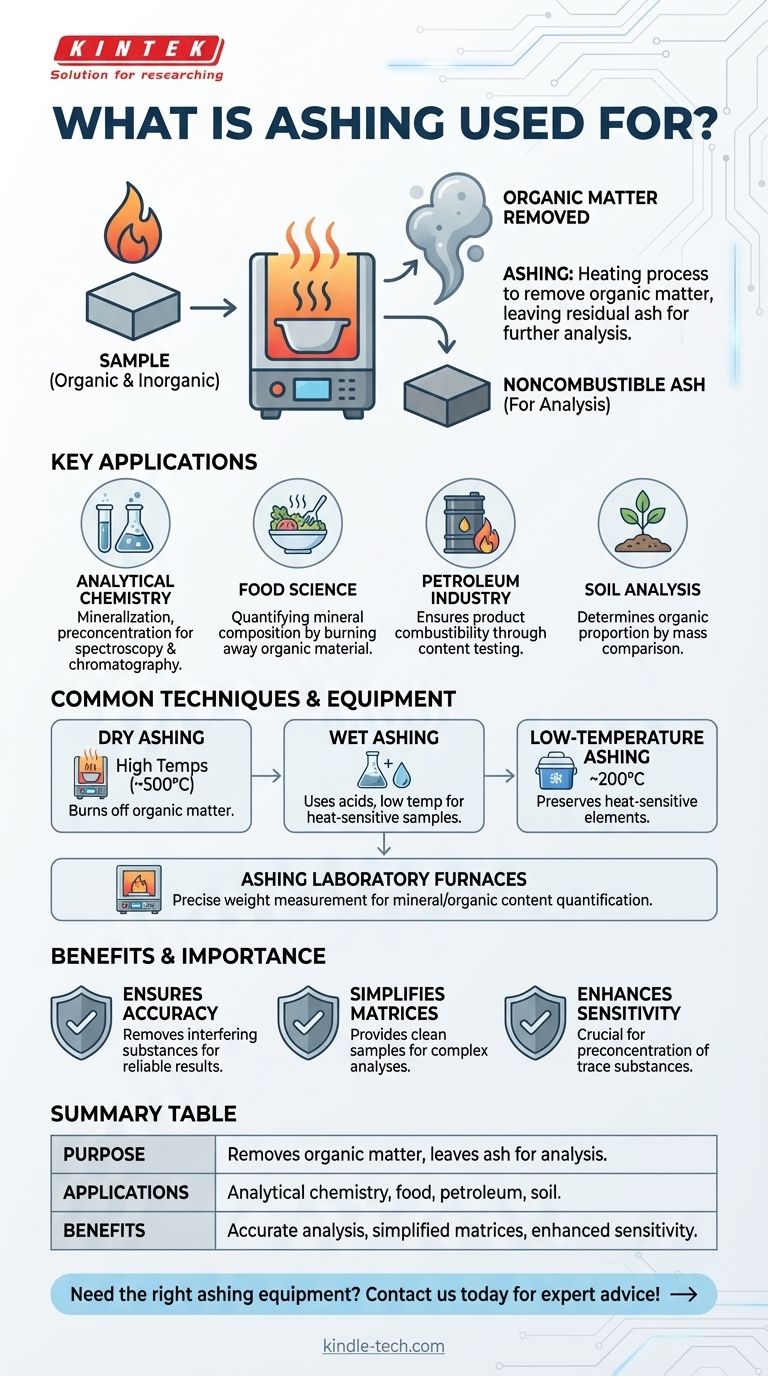

灰化是各行业和科学领域中一项关键的工艺,用于去除样品中的有机物和其他干扰成分,留下不可燃的灰分以供进一步分析。它常用于分析化学、食品科学、石油测试和土壤分析。根据样品类型和分析要求,可采用干灰化、湿灰化和低温灰化等技术。灰化有助于量化矿物质组成,确保产品的可燃性,并为光谱和色谱等技术制备样品。它对于痕量物质的预浓缩以及确定土壤等材料中的有机物比例也至关重要。

关键点解释:

-

灰化的定义和目的

- 灰化是一种通过加热样品来去除有机物和其他干扰基质成分,留下不可燃灰分的过程。

- 它主要用于通过消除可能干扰测量的成分来制备样品以进行准确分析。

-

灰化的应用

- 分析化学:灰化用于在化学或光学分析(如色谱或光谱)之前对痕量物质进行矿化和预浓缩。

- 食品科学:通过燃烧有机物来帮助量化食品样品中的矿物质组成。

- 石油工业:灰化通过测试石油产品的含量来确保其可燃性。

- 土壤分析:通过比较灰化前后的质量来确定土壤的有机物比例。

-

常见的灰化技术

- 干灰化:涉及在高温(约500°C)下加热样品以烧掉有机物。

- 湿灰化:使用酸而不是高温来去除有机成分,适用于热敏样品。

- 低温灰化:在较低温度(约200°C)下进行,以保护热敏元素。

- 硫酸灰化:中和并去除样品中的二氧化硫。

- 密闭系统灰化:使用密闭腔室在过程中控制气氛,确保精确度。

-

在石墨炉原子吸收(AA)中的作用

- 灰化是石墨炉AA程序中的关键步骤,它去除可能干扰分析物测量的基质成分。

- 此步骤确保了元素分析的准确可靠结果。

-

在样品制备中的重要性

- 灰化简化了样品基质,使得更容易分析残留灰分的元素组成。

- 它在痕量物质的预浓缩中特别有用,提高了分析技术的灵敏度。

-

灰化中使用的设备

- 灰化实验室炉:设计用于测量样品中有机成分燃烧掉后的重量变化。

- 这些炉子对于需要精确量化矿物质或有机物含量的行业至关重要。

-

灰化的好处

- 通过去除干扰物质确保准确分析。

- 为光谱和色谱等技术提供干净的样品基质。

- 有助于量化各种材料中的矿物质含量和有机物比例。

通过了解这些关键点,设备和耗材采购人员可以更好地理解灰化在样品制备和分析中的重要性,确保他们为特定需求选择正确的工具和技术。

总结表:

| 方面 | 详情 |

|---|---|

| 目的 | 去除有机物,留下不可燃灰分以供分析。 |

| 应用 | 分析化学、食品科学、石油测试、土壤分析。 |

| 技术 | 干灰化、湿灰化、低温灰化、硫酸灰化。 |

| 设备 | 用于精确重量测量的灰化实验室炉。 |

| 好处 | 确保准确分析,简化样品基质,提高灵敏度。 |

需要适合您实验室的灰化设备吗?立即联系我们获取专家建议和解决方案!

图解指南