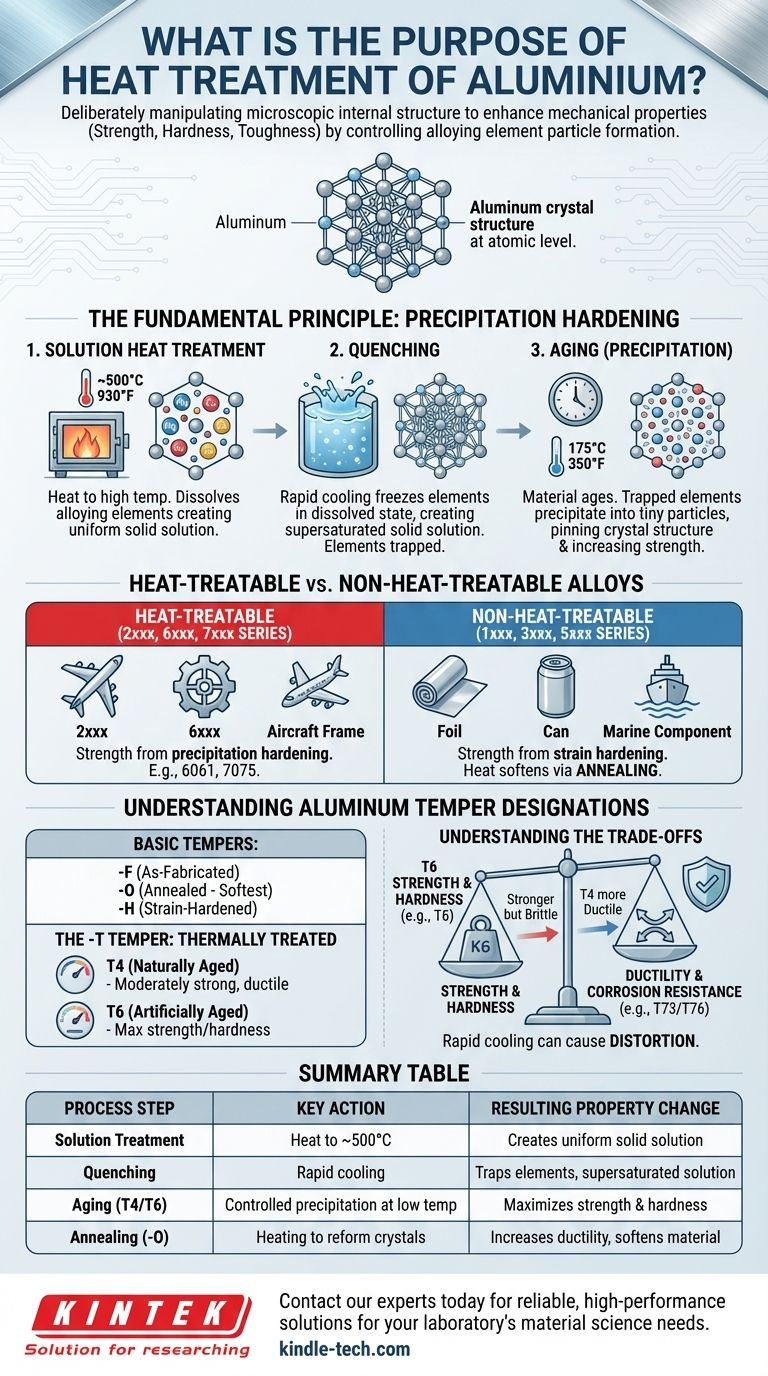

从根本上讲,铝热处理的目的是有意识地控制其微观内部结构,以增强其机械性能。与通过改变晶体相来硬化的钢不同,铝合金最常见和最有效的热处理是通过控制金属内合金元素微小颗粒的形成来提高强度、硬度和韧性。

热处理铝的核心目标不仅仅是使其变硬,而是实现精确的、工程化的性能平衡。该过程通过创建抗变形的内部析出物精细分散网络,释放出特定铝合金的高强度潜力。

基本原理:时效硬化

要理解热处理,您必须首先了解并非所有铝都是相同的。该过程仅对特定的“可热处理”合金有效。

纯铝的问题

纯铝(1xxx 系列)柔软、延展性好,强度相对较低。虽然因其耐腐蚀性和导电性而有用,但它不适用于大多数结构应用。

引入合金元素

为了提高强度,铝与铜 (Cu)、镁 (Mg) 和锌 (Zn) 等其他元素混合。在可热处理合金(如 2xxx、6xxx 和 7xxx 系列)中,这些元素可以溶解到铝中,然后以受控的方式析出。

三步强化过程

这个过程被称为时效硬化或人工时效,最好理解为一个三个阶段的顺序。

-

固溶处理: 将铝合金加热到特定的高温(约 500°C / 930°F)并保持。这会将合金元素溶解到铝中,形成均匀的固溶体,就像在热水中溶解糖一样。

-

淬火: 然后材料快速冷却,通常在水中。这种突然的温度下降将合金元素“冻结”在其溶解状态,形成过饱和固溶体。这些元素被困在铝的晶格内,想要逸出但没有足够的热能做到这一点。

-

时效(析出): 在最后、关键的步骤中,材料被允许“老化”。被困的合金元素开始聚集并从溶液中析出,形成极其微小、数量众多且均匀分散的颗粒。这些颗粒充当障碍物,将晶体结构固定到位,使材料更难变形。这就是强度和硬度急剧增加的原因。

可热处理合金与不可热处理合金

这一区别对于任何涉及铝的工程或设计决策都至关重要。

可热处理合金(2xxx、6xxx、7xxx 系列)

这些合金专为时效硬化而设计。它们的强度主要来源于热处理过程。

- 2xxx 系列(铝-铜): 以高强度著称,但通常耐腐蚀性较低。常用于航空航天应用。

- 6xxx 系列(铝-镁-硅): 像 6061 这样的主力合金。它们在强度、成形性和耐腐蚀性之间提供了良好的平衡。

- 7xxx 系列(铝-锌-镁): 强度最高的铝合金,例如 7075。它们是高应力结构部件(如飞机框架)的首选。

不可热处理合金(1xxx、3xxx、5xxx 系列)

这些合金的强度是通过加工硬化(冷加工,如轧制或成形)和合金元素的固溶强化获得的。热处理不能用于强化它们。

然而,热处理可用于通过称为退火的过程来软化这些合金。这消除了加工硬化的影响,使材料更具延展性,更容易成形。

理解铝的硬度状态代号

硬度状态代号是跟在合金牌号后面的后缀(例如 6061-T6),它准确地告诉您对材料进行了什么处理。

基本状态代号:-F、-O 和 -H

- -F (加工态): 没有对热处理或加工硬化条件进行特殊控制。

- -O (退火态): 最柔软、延展性最好的状态,通过加热使晶体重新形成来实现。

- -H (加工硬化态): 仅适用于通过冷加工强化的不可热处理合金。

-T 状态代号:热处理态

-T 代号表示合金已经过热处理以产生稳定的硬度状态。它后面总是跟着一个或多个数字。

- -T4 (自然时效): 材料经过固溶处理、淬火,然后允许在室温下老化。它具有相当的强度,但仍具有足够的延展性以进行某些成形操作。

- -T6 (人工时效): 在固溶处理和淬火后,材料在低温下(例如 175°C / 350°F)加热特定时间。“人工时效”加速并优化了析出过程,从而实现了接近最大的强度和硬度。这是结构铝最常见的硬度状态。

理解权衡

热处理并非没有代价;每项增强都有相应的权衡。

强度与延展性的权衡

主要的权衡在于强度和延展性之间。完全时效的 T6 状态比自然时效的 T4 状态明显更强,但它也更脆,不易成形。退火的 -O 状态延展性最好,但强度最低。

强度与耐腐蚀性的权衡

对于某些高强度合金(尤其是 7xxx 系列),T6 等峰值强度状态更容易受到应力腐蚀开裂 (SCC) 的影响。为对抗这种情况,会使用特殊的“过时效”状态,如 T73 或 T76,它们会略微降低峰值强度,以换取耐腐蚀性的显著提高。

变形的风险

淬火的快速冷却是一种热冲击,可能导致复杂部件发生显著变形和内部应力。这需要仔细的过程控制、专用夹具,有时还需要淬火后的矫直或去应力处理。

为您的应用做出正确的选择

您选择的合金和热处理必须由部件的最终用途要求来决定。

- 如果您的主要重点是最大强度和硬度: 选择像 6061 或 7075 这样的可热处理合金,并指定 T6 状态。

- 如果您的主要重点是成形性和延展性: 在退火(-O)状态下使用不可热处理合金,或者使用可热处理合金的 T4 状态进行成形,然后再将其老化到最终状态。

- 如果您的主要重点是在强度和抗应力腐蚀开裂之间取得平衡: 为用于腐蚀环境的关键 7xxx 系列部件指定 T73 等过时效状态。

- 如果您只需要软化材料以便返工或成形: 您所需的过程是退火,它适用于所有铝合金,并产生 -O 状态。

理解这些原理,您就能选择正确的材料和工艺来满足您部件的特定性能要求。

摘要表:

| 工艺步骤 | 关键操作 | 由此产生的性能变化 |

|---|---|---|

| 固溶处理 | 加热至约 500°C 以溶解合金元素 | 形成均匀的固溶体 |

| 淬火 | 快速冷却(例如,水冷) | 捕获元素,形成过饱和溶液 |

| 时效 (T4/T6) | 低温下的受控析出 | 通过颗粒分散实现强度和硬度的最大化 |

| 退火 (-O) | 加热以重新形成晶体 | 提高材料的延展性并使其软化 |

需要为您的实验室或生产找到合适的铝热处理解决方案吗? KINTEK 专注于材料测试和加工的精密实验室设备和耗材。我们的专业知识可确保您获得应用所需的精确机械性能——无论是最大强度 (T6)、延展性 (-O) 还是耐腐蚀性 (T73)。立即联系我们的专家,讨论我们如何用可靠、高性能的解决方案支持您实验室的材料科学需求。

图解指南