为什么选择我们

简易的订购流程、优质的产品和专业的支持,助力您的业务成功。

应用

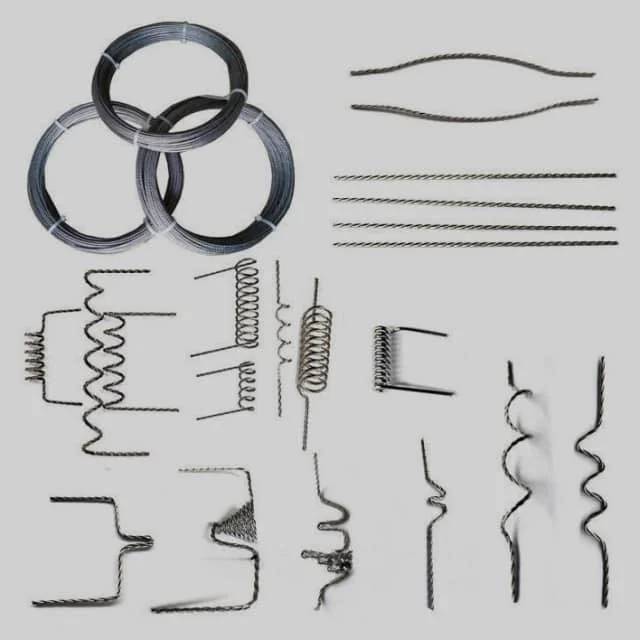

钨丝是通过在氢气气氛中压制钨粉、烧结、模锻、拉丝和退火制成的。这个过程会引起金属性能的巨大变化。钨具有高熔点、高电阻率、良好的强度和低蒸气压,是制造加热元件的理想材料。多股钨丝可用于生产真空丝。常用于电子束源、真空镀膜、灯丝、热电子发射器、电子枪束等领域。

详情与部件

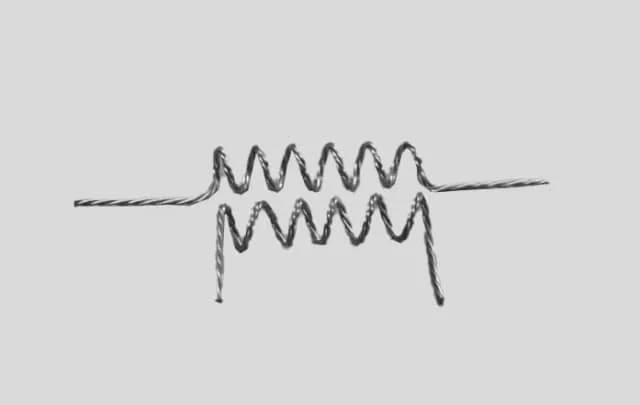

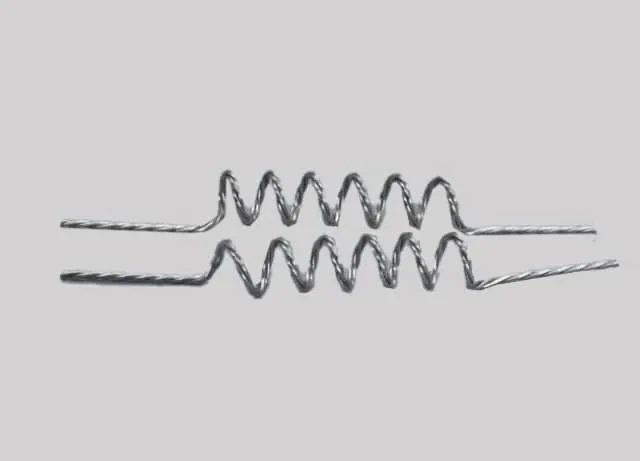

技术规格

规格:长度 100 毫米;6 圈

我们展示的坩埚有不同尺寸可供选择,也可根据要求定制尺寸。

优点

- 高熔点,高电阻。

- 低热膨胀系数。

- 良好的导电性和导热性,

- 抗氧化和抗蠕变

- 极高的硬度,高抗拉强度。

- 所有金属中最低的蒸气压。

行业领军企业信赖之选

4.9 / 5

The tungsten wire arrived promptly and in perfect condition, meeting all my research specifications. Highly recommend KINTEK SOLUTION for their reliable service.

4.8 / 5

Excellent value for money! The tungsten wire's exceptional quality has enhanced our lab's research capabilities. Thank you, KINTEK SOLUTION, for providing such a cost-effective solution.

4.7 / 5

KINTEK SOLUTION's tungsten wire is of impeccable quality, ensuring precise and reliable results in our experiments. Highly satisfied with the product's performance and durability.

5.0 / 5

The tungsten wire's exceptional durability has exceeded our expectations. It has withstood countless experiments, maintaining its structural integrity and delivering consistent results. Highly recommend!

4.9 / 5

The tungsten wire's technological advancement has revolutionized our research. Its unique properties have enabled groundbreaking discoveries and pushed the boundaries of our scientific understanding.

4.7 / 5

KINTEK SOLUTION's tungsten wire has been an invaluable asset to our lab. Its consistent quality and exceptional performance have contributed to the success of numerous experiments.

5.0 / 5

The tungsten wire's rapid delivery was a lifesaver! It arrived just in time for a crucial experiment, ensuring our research stayed on schedule. Thank you, KINTEK SOLUTION, for your outstanding service.

4.8 / 5

The tungsten wire's versatility has been remarkable. We've used it in various applications, and it has consistently exceeded our expectations. A must-have for any lab.

4.9 / 5

The tungsten wire's exceptional quality has enhanced our lab's research capabilities. Highly satisfied with the product's performance and durability.

5.0 / 5

The tungsten wire's exceptional durability has exceeded our expectations. It has withstood countless experiments, maintaining its structural integrity and delivering consistent results. Highly recommend!

4.9 / 5

The tungsten wire's technological advancement has revolutionized our research. Its unique properties have enabled groundbreaking discoveries and pushed the boundaries of our scientific understanding.

4.7 / 5

KINTEK SOLUTION's tungsten wire has been an invaluable asset to our lab. Its consistent quality and exceptional performance have contributed to the success of numerous experiments.

5.0 / 5

The tungsten wire's rapid delivery was a lifesaver! It arrived just in time for a crucial experiment, ensuring our research stayed on schedule. Thank you, KINTEK SOLUTION, for your outstanding service.

4.8 / 5

The tungsten wire's versatility has been remarkable. We've used it in various applications, and it has consistently exceeded our expectations. A must-have for any lab.

4.9 / 5

The tungsten wire's exceptional quality has enhanced our lab's research capabilities. Highly satisfied with the product's performance and durability.

5.0 / 5

The tungsten wire's exceptional durability has exceeded our expectations. It has withstood countless experiments, maintaining its structural integrity and delivering consistent results. Highly recommend!

获取报价

我们的专业团队将在一个工作日内回复您。请随时与我们联系!

相关产品

小型真空热处理及钨丝烧结炉

小型真空钨丝烧结炉是一款专为高校和科研院所设计的紧凑型实验真空炉。该炉采用CNC焊接炉壳和真空管道,确保无泄漏运行。快速连接的电气接口便于搬迁和调试,标配的电控柜操作安全便捷。

弧形氧化铝陶瓷坩埚 高温耐受工程先进陶瓷

在科学探索和工业生产的征程中,每一个细节都至关重要。我们的弧形氧化铝陶瓷坩埚,凭借其出色的耐高温性和稳定的化学性质,已成为实验室和工业领域的得力助手。它们采用高纯度氧化铝材料制成,并经过精密工艺制造,确保在极端环境下也能有卓越的表现。

相关文章

探索使用钨加热炉的好处

钨的许多特性使其非常适合用于高温熔炉。

为热等静压机选择合适温度的指南

热等静压(WIP)是一种用于消除孔隙和改善材料机械性能的工艺。在这一工艺中,材料在惰性气体环境中承受高压和高温。

真空镀膜综合指南》:提高性能和美感

探索真空镀膜的世界,这是一种在金属和塑料表面形成保护层和美观层的工艺。探索真空镀膜的类型、用途和优点,包括提高性能、延长使用寿命和改善美观度。

等静压工艺是挤压工艺的低失真替代工艺

等静压是一种利用高压将粉末状材料压缩成特定形状或形态的制造工艺。

如何使用热等静压机确保成型质量和效率

热等静压(WIP)是等静压的一种,它利用热量和压力的组合来制造高质量的零件。WIP 工艺包括将零件放入柔性模具中,然后在模具中注入气体或液体介质。

蒸发涂层的蒸发源类型

探索薄膜沉积中使用的不同蒸发源,包括灯丝、坩埚和蒸发舟。

马弗炉电阻丝设计综合指南

详细分析马弗炉应用中的电阻丝设计原理、参数和计算技术。

在真空沉积设备中开发和应用钽所面临的挑战

本文讨论了钽在真空沉积设备中的作用,重点关注其特性、制造挑战及其在 OLED 屏幕生产等行业中的关键应用。

在磁控溅射中使用铼靶实现辉光放电所面临的挑战

探讨铼靶在磁控溅射过程中难以发光的原因,并提出优化建议。

常见的实验室熔化方法

概述三种主要的实验室熔化技术:电弧熔化、感应熔化和悬浮熔化。

为真空炉选择加热元件

关于选择加热元件和隔热屏以实现真空炉高效运行的指南。