陶瓷加热器

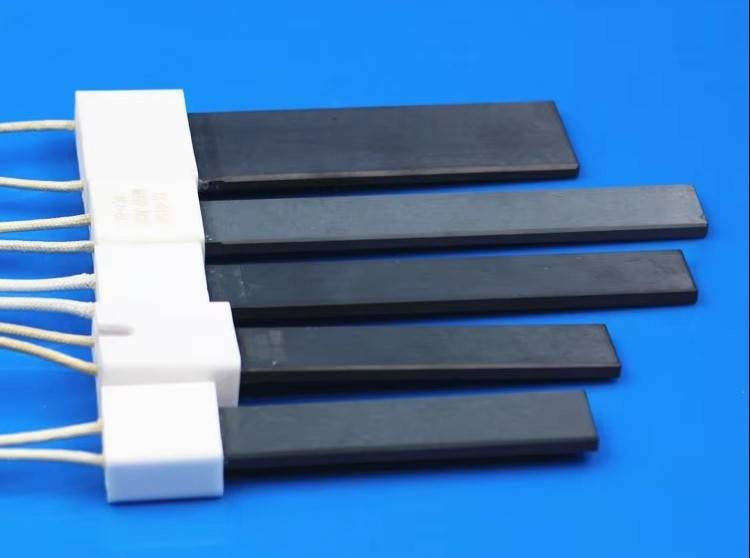

氮化硅加热器

氮化硅加热器在各种应用领域,特别是汽车和电子行业中的应用日益突出。氮化硅加热器的主要用途之一是柴油发动机的启动预热,即使在寒冷的条件下也能确保快速有效的点火。氮化硅加热器也是高温气体点火系统中不可或缺的部件,可促进各种工业环境中的燃烧过程。

氮化硅加热器的新兴应用领域还包括先进的制造工艺,如 5G 智能手机的曲面玻璃加工。氮化硅的独特性能,包括强大的抗氧化能力和耐腐蚀性,使其成为这些高要求应用的理想材料。氮化硅加热器不仅能防止自氧化和老化,还能提供自动清洁功能,确保加热元件在积垢达到临界厚度时脱落,从而保持高效。

此外,氮化硅加热元件的耐腐蚀性能比不锈钢强十倍,可将使用寿命大幅延长至 5000 至 15000 小时。在燃气炉和柴油发动机火花塞等高温和腐蚀性物质普遍存在的环境中,这种耐用性至关重要。这些加热元件的温度高达 1,400 °C,可快速点燃燃气、柴油或煤油,从而提高运行效率和可靠性。

氧化铝加热器

氧化铝加热器是高度可靠的工业元件,能够承受高达 1,000°C 的极端温度。这种 先进陶瓷 材料具有优异的耐热性和稳定性,是各种高温应用的理想选择。

氧化铝加热器最具创新性的用途之一是在智能厕所领域,精确的温度控制对用户的舒适度和卫生至关重要。这些加热器可确保稳定的温度,提升现代浴室技术的整体体验。

除智能马桶外,氧化铝加热器在气体传感器技术中也发挥着至关重要的作用。它们能够保持高温而不降解,这对气体传感器的准确可靠运行至关重要,而气体传感器是环境监测和安全系统不可或缺的组成部分。

| 应用 | 温度范围 | 主要优点 |

|---|---|---|

| 智能马桶加热器 | 高达 1,000°C | 确保始终如一的温暖和卫生 |

| 气体传感器加热器 | 高达 1,000°C | 保持高温,确保传感器精度 |

氧化铝加热器在这些不同应用中的强劲性能,突出表明了其在要求苛刻的工业环境中的多功能性和可靠性。

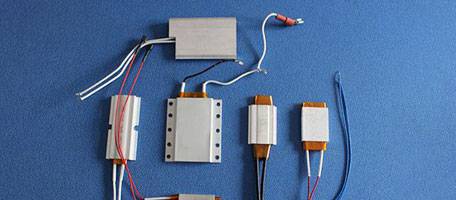

PTC 陶瓷加热器

PTC (正温度系数)陶瓷以其独特的热特性而闻名,尤其是正电阻温度系数,这意味着其电阻会随温度的升高而增大。与负温度系数的传统陶瓷不同,通常由钛酸钡和钛酸铅复合材料组成的 PTC 陶瓷具有高度非线性的热响应。超过一定的临界温度后,它们的电阻会迅速上升,从而成为自调节加热器。PTC 陶瓷的这一固有特性使其能够发挥高效恒温器的作用,在冷却时导电,在加热时停止导电。

这些陶瓷广泛应用于汽车、空调、暖风机和烘干机等各个领域。在汽车行业,PTC 陶瓷薄膜是后窗除霜加热器的组成部分,可确保在恶劣天气条件下的清晰视野。在高端吹风机和空间加热器等更高级的应用中,蜂窝状 PTC 元件因其出色的热量分布和快速的温度稳定性而得到广泛应用。这些元件的温度可高达 950-1000 °C,因此非常适合需要在较低功率和电压下精确控制温度的工业加热应用。

PTC 陶瓷加热器的多功能性还延伸到了无法使用传统炉子的工业领域。与工业炉相比,这些加热器的工作温度较低,但却能提供无与伦比的精确温度调节,因此适用于需要稳定和可控热量的点加热应用。这种适应性凸显了 PTC 陶瓷在现代加热技术中的广泛用途。

压电陶瓷

应用领域

压电陶瓷是一种多功能材料,可将机械能转化为电能,反之亦然。压电陶瓷的独特性能使其在各行各业的各种应用中都不可或缺。

-

谐振器:压电陶瓷与谐振器的功能密不可分,而谐振器是振荡器和滤波器等电子设备的关键部件。这些谐振器可确保稳定和精确的频率控制,对通信系统和信号处理设备的运行至关重要。

-

传感器:压电陶瓷能够在机械应力作用下产生电荷,因此非常适合用于传感器。这些传感器的应用范围从医疗诊断到工业自动化,可提供压力、力和加速度的精确测量。

-

超声波传感器:压电陶瓷是超声波传感器的骨架,可将电信号转换为超声波。这些传感器可用于医学成像、无损检测和水下声纳系统,实现对物体和材料的精确检测和分析。

-

致动器:在致动器领域,压电陶瓷可将电能转化为机械运动。在微定位系统、精密机器人技术和自适应光学领域,这种能力得到了充分利用,因为在这些领域,精细控制和高精度是至关重要的。

压电陶瓷的多方面应用凸显了其在现代技术中的重要地位,推动了各个领域的进步,促进了创新解决方案的开发。

常用材料

在压电陶瓷领域,有几种材料因其独特的性能和广泛的应用而脱颖而出。 钛酸钡 是一种典型的选择,它以高介电常数和出色的压电特性而著称,是谐振器和传感器的理想材料。它能将机械应力转化为电能,反之亦然,这在许多应用中都是无与伦比的。

锆钛酸铅(PZT) 通常被称为压电陶瓷中的 "主力军",具有出色的压电系数和机械品质因数组合。PZT 因其强大的性能和可靠性,被广泛应用于超声波传感器、致动器和高精度传感器。这种材料具有多功能性,可通过调整锆和钛的比例为特定应用量身定制。

另一种值得注意的材料是 铅铌镁氧化物(PMN) 这种材料具有优异的压电特性,尤其是在高灵敏度应用中。PMN 通常用于先进的传感器和致动器中,这些传感器和致动器需要精确检测微小的机械变化并将其转换为电信号。独特的晶体结构造就了它的高灵敏度和低滞后性,使其成为尖端技术的首选。

| 材料 | 主要特性 | 应用 |

|---|---|---|

| 钛酸钡 | 介电常数高,压电性能优异 | 谐振器、传感器 |

| 锆酸铅钛 (PZT) | 高压电系数、机械品质因数 | 超声波传感器、致动器 |

| 氧化镁铌铅(PMN) | 高灵敏度、低滞后 | 先进传感器、执行器 |

这些材料不仅是开发压电器件的基础,而且还将继续推动各种能源转换技术的创新。

固体氧化物燃料电池 (SOFC)

应用

固体氧化物燃料电池(SOFC)以其将化学能有效转化为电能的能力而闻名,因此成为多个领域的通用解决方案。在需要可靠和可持续能源的环境中,这些燃料电池尤其具有优势。

SOFC 的主要应用之一是通信基站。这些基站需要持续稳定的电力供应,以确保不间断的通信服务。SOFC 可提供可靠的能源,尤其是在传统电力基础设施无法使用或不可靠的偏远或离网地区。

在住宅环境中,SOFC 可以集成到家庭能源系统中,提供电力和热能。这种双重功能使其成为寻求减少碳足迹和能源成本的业主的一个极具吸引力的选择。安静的运行和最低的维护要求进一步增强了其在家庭应用中的吸引力。

商业机构也能从 SOFC 的应用中获益。企业,尤其是那些需要连续运行的行业,如数据中心和制造设施,可以利用 SOFC 来确保不间断供电。SOFC 的高效率可显著节约成本并减少对环境的影响,因此成为商业实体的一项战略性投资。

总之,SOFC 的多功能性和高效率使其成为从电信到住宅和商业能源解决方案等广泛应用的前景广阔的技术。

常见固体电解质

在固体氧化物燃料电池(SOFC)领域,有几种陶瓷材料起着关键作用,尤其是在固体电解质方面。其中包括 氧化锆 (ZrO₂) , 氧化铈 (CeO₂) 和 氧化铋 (Bi₂O₃) -基电解质因其独特的性质和潜在的应用而备受关注。用钇稳定的氧化锆因其在高温下的高离子导电性而闻名,因此成为 SOFC 的首选。另一方面,铈具有出色的氧离子传导性,可在较低温度下工作,这对降低整个系统的复杂性和成本尤为有利。以氧化铋为基础的电解质虽然不太常见,但具有高导电性,目前正在探索其提高 SOFC 性能的潜力。

除此之外,还有 没食子酸镧锶 (LSGM) 和 钼酸镧(La₂Mo₂O₉)也值得一提。 也值得一提。LSGM 因其在广泛的氧分压和温度范围内的稳定性和导电性而闻名,使其成为各种 SOFC 配置的通用选择。然而,它对硫中毒和碳沉积的敏感性仍然是一个关键的研究领域。La₂Mo₂O₉虽然研究较少,但却表现出良好的导电性和稳定性,特别是在还原环境中,这可以扩大其在各种 SOFC 系统中的应用。

上述每种材料都具有独特的优势和挑战,推动着人们不断进行研究,以优化它们的性能,并将它们更有效地集成到 SOFC 技术中。

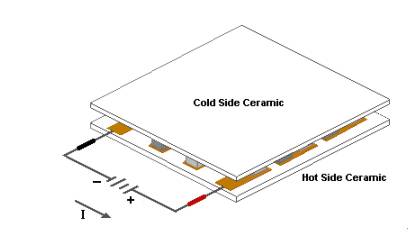

热电冷却模块

应用领域

热电半导体致冷片广泛应用于多个行业,每个行业都能利用其独特的功能实现精确的温度控制。在 半导体行业 这些模块对于保持敏感电子元件的最佳工作条件、确保其性能稳定和使用寿命是不可或缺的。

在 消费电子产品 笔记本电脑、游戏机和智能手机等设备可利用热电冷却技术防止过热,从而提升用户体验。这项技术不仅能延长这些设备的使用寿命,还能确保在长时间使用过程中性能不间断。

汽车行业 汽车行业 采用热电冷却模块来管理从发动机控制单元到信息娱乐系统等各种组件的温度。这种精确的温度控制对于提高汽车的可靠性和性能至关重要,尤其是在极端环境条件下。

此外,在 通信行业 这些模块在维持基站和网络设备等关键基础设施的功能方面发挥着至关重要的作用。通过确保稳定的工作温度,热电冷却有助于维持不间断的通信服务,这对城市和偏远地区都至关重要。

| 行业 | 应用实例 |

|---|---|

| 半导体 | 保持电子元件的最佳工作温度 |

| 消费电子产品 | 防止笔记本电脑、游戏机和智能手机过热 |

| 汽车 | 管理发动机控制单元和信息娱乐系统的温度 |

| 通信 | 确保基站和网络设备的稳定运行 |

这些不同的应用凸显了热电半导体制冷模块在现代技术中的多功能性和关键作用,确保了各个领域高效可靠的性能。

相关材料

在半导体致冷片领域,有几种陶瓷材料在提高能量转换效率方面发挥着举足轻重的作用。 氧化铝 (Al2O3) , 氧化铍(BeO) 和 氮化铝(AlN) 是这些模块中不可或缺的组成部分,每种材料都具有优化导热性和电绝缘性的独特性能。

另一方面,碲化铋基合金经常被用作半导体热电材料。这些合金因能够有效地将温差转化为电能而闻名,因此非常适合半导体制造、消费电子、汽车和通信行业等需要精确温度控制的应用。

| 材料 | 主要特性 | 应用 |

|---|---|---|

| 氧化铝 | 高导热性、电绝缘性 | 热电模块 |

| 氧化铍 | 热导率高、介电常数低 | 先进的热电应用 |

| 氮化铝 | 高导热性、良好的电绝缘性 | 高性能热电模块 |

| 碲化铋 | 高效的温度-能量转换 | 半导体热电材料 |

这些材料不仅对半导体致冷片的功能至关重要,而且还推动了各行各业节能技术的创新。

相关产品

- 用于工程先进陶瓷的精密加工氮化硅(SiN)陶瓷板

- 碳化硅(SiC)电炉加热元件

- 工程用高级精密陶瓷高温氧化铝(Al2O3)保护管

- 先进工程精密陶瓷氮化硼(BN)陶瓷件

- 二硅化钼 (MoSi2) 热元件 电炉加热元件