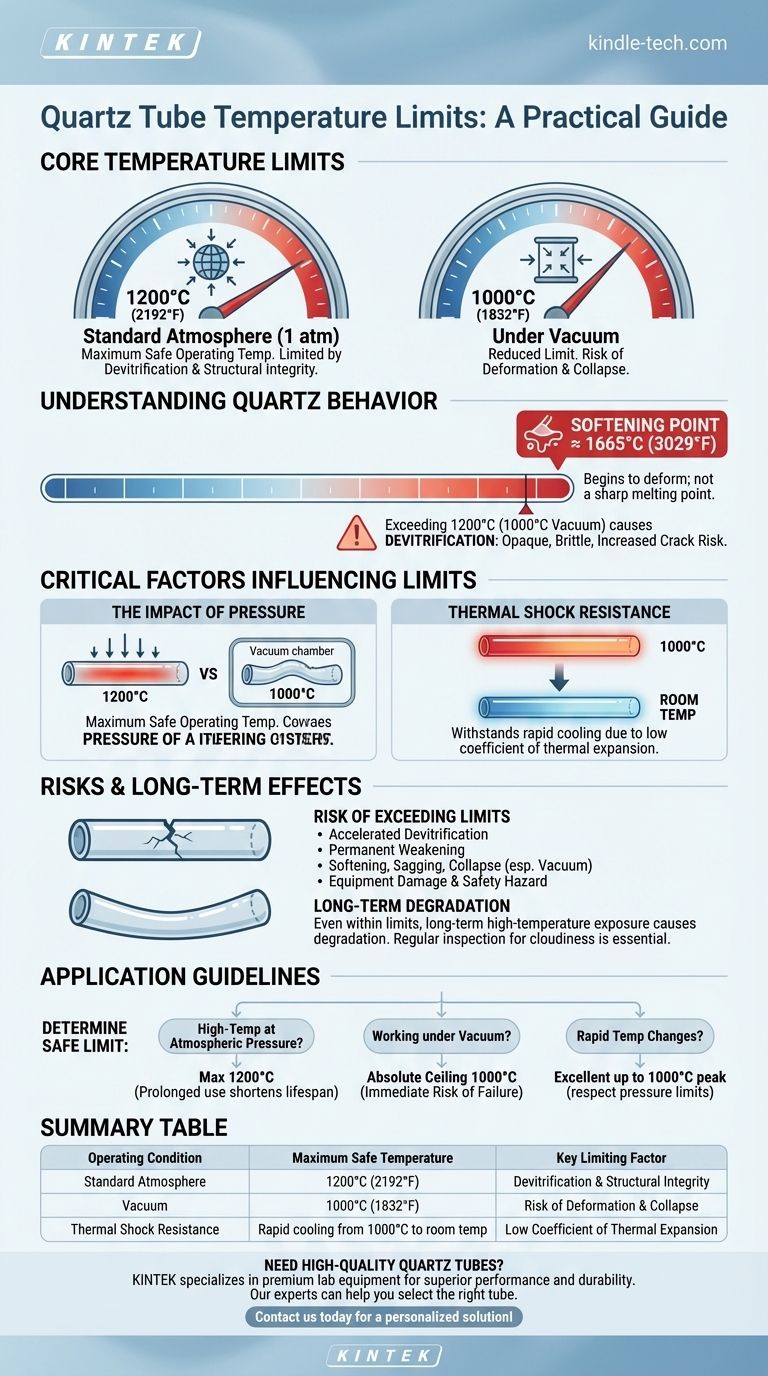

标准石英管的最高工作温度通常在标准大气压下约为1200°C(2192°F)。这个值并非绝对,因为有效温度极限高度依赖于操作环境。关键是,在真空条件下使用时,此极限会降低到大约1000°C(1832°F)。

石英管的温度额定值不是一个单一的数字,而是其工作条件的函数。其实际上限由压力、暴露时间以及材料降解风险等因素决定,而不仅仅是其理论熔点。

为什么单一温度不能说明全部情况

虽然我们经常寻找一个单一的数字,但石英在高温下的行为是复杂的。了解材料的不同热点对于安全使用并防止过早失效至关重要。

真正的熔点

熔融石英不像晶体材料那样具有尖锐、明确的熔点。相反,它有一个软化点,大约在1665°C(3029°F)左右,此时它开始在自身重量下变形。这远高于其实际使用极限。

实际操作极限

建议的最高温度1200°C是连续使用的实用指导。超过此温度,可能会发生一种称为失透的过程。石英的无定形玻璃结构开始缓慢结晶,使其变得不透明、易碎,并且在冷却时更容易开裂。

定义实际极限的关键因素

石英管的官方温度额定值总是受到具体应用的影响。其中有两个因素至关重要。

压力的影响

压力是最重要的变量。在标准大气压(1个大气压)下,石英管在高达1200°C的温度下仍能保持其结构完整性。

在真空下,缺乏外部压力使得管子在高温下更容易变形和坍塌。因此,最高安全工作温度降低到1000°C。

抗热震性

石英最大的优点之一是其极低的线性热膨胀系数。这赋予了它卓越的抗热震性。

石英管可以承受从高达1000°C到室温的快速温度骤降而不会破裂。这使其成为涉及快速加热和冷却循环应用的理想选择。

理解权衡

将石英管推到超出其推荐极限会带来巨大的风险,并且很少值得潜在的后果。

超出极限的风险

在1200°C以上(或真空下1000°C以上)操作会显著增加失透的速度。这会永久性地削弱管子。

更直接的是,管子会开始软化并可能下垂、变形,甚至坍塌,尤其是在真空下。这可能会损坏您的设备,毁掉您的实验,并造成严重的安全隐患。

长期降解

即使在规定范围内操作,长期暴露于高温也会最终导致石英降解。定期检查管子是否有浑浊(结晶)或变形的迹象对于安全操作至关重要。

如何确定您应用的安全极限

使用这些指南来选择适合您目标的正确操作参数。

- 如果您的主要关注点是在大气压下进行高温处理:您可以安全地操作到1200°C,但请注意,长时间接近此极限使用会缩短管子的寿命。

- 如果您的主要关注点是在真空下工作:您的绝对上限是1000°C。超过此温度会立即带来结构失效的风险。

- 如果您的主要关注点涉及快速温度变化:石英是一个极佳的选择。您可以在不损坏的情况下从高达1000°C进行快速冷却,前提是峰值温度符合压力限制。

遵守这些操作边界是安全有效地利用石英独特性能的关键。

总结表:

| 操作条件 | 最高安全温度 | 关键限制因素 |

|---|---|---|

| 标准大气压 | 1200°C (2192°F) | 失透和结构完整性 |

| 真空 | 1000°C (1832°F) | 变形和坍塌风险 |

| 抗热震性 | 从1000°C快速冷却至室温 | 低热膨胀系数 |

需要根据您的具体温度和压力要求定制高质量石英管吗? KINTEK专注于优质实验室设备和耗材,提供专为在严苛实验室环境中实现卓越性能和耐用性而设计的石英管。我们的专家可以帮助您选择合适的管子,以确保您高温应用的安全性和效率。立即联系我们,讨论您的需求并获取个性化解决方案!

图解指南