是的,您绝对可以在PVD表面上应用陶瓷涂层。高质量的陶瓷涂层将有效地与PVD(物理气相沉积)饰面结合,提供额外的保护层并增强其性能。成功的关键不在于是否可能,而在于应用前细致的表面准备。

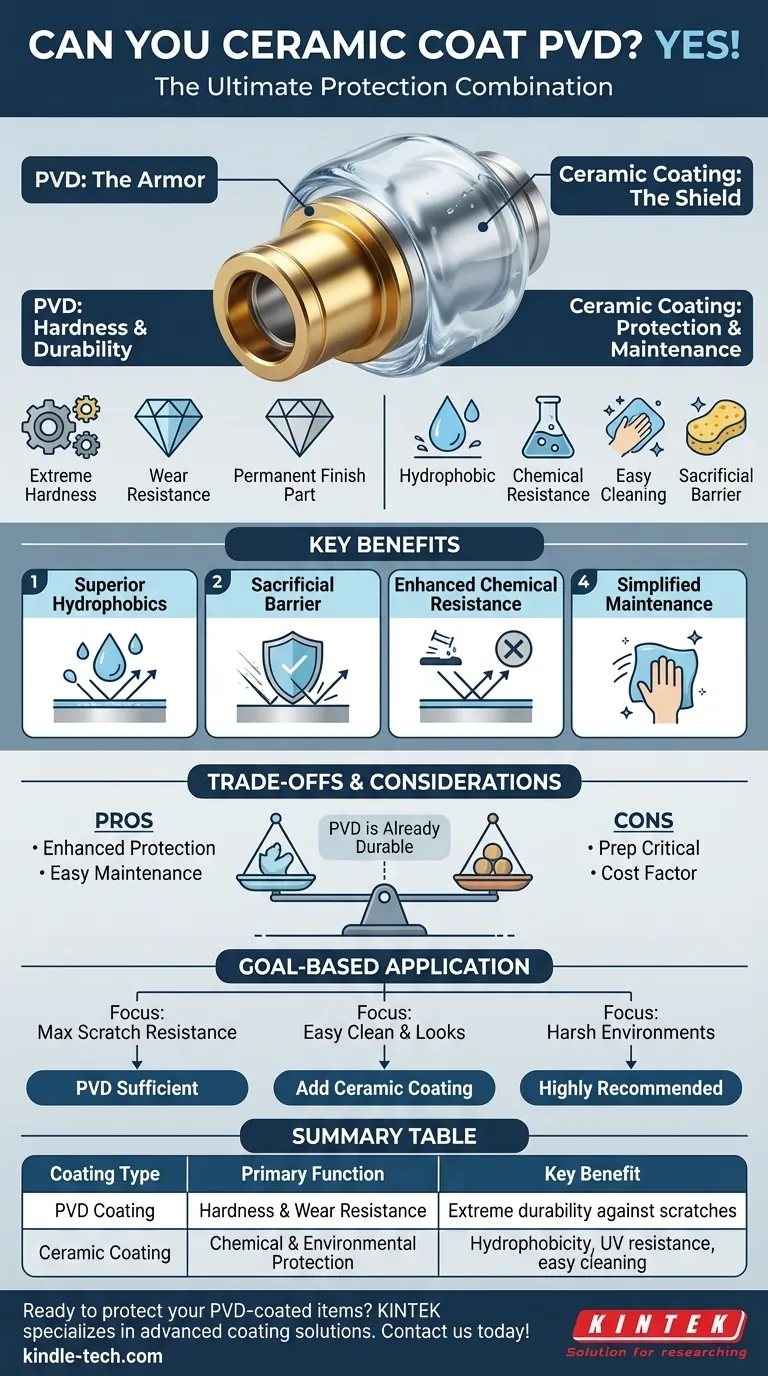

虽然PVD提供了卓越的硬度和耐磨性,但陶瓷涂层增加了互补的优势:卓越的耐化学性、疏水性和牺牲性屏障。可以将PVD视为盔甲,而陶瓷涂层则是保护盔甲的隐形自清洁护盾。

两种涂层的作用

要理解为什么要结合这两种技术,必须认识到它们各自独特的功能。它们并非冗余;它们服务于不同的主要目的。

PVD提供什么:硬度和耐用性

PVD是一种将非常薄、极其坚硬的金属或陶瓷材料层沉积到基材上的工艺。其主要优点是耐用性和耐磨性。

PVD涂层是物品饰面的基本组成部分。正如参考文献所指出的,它完美地贴合底层表面,这意味着抛光部件将具有抛光的PVD饰面,而拉丝部件将具有拉丝的PVD饰面。

陶瓷涂层提供什么:保护和维护

陶瓷涂层是一种液态聚合物,通过化学键与表面结合,形成一层半永久性的透明保护层。其主要优点是环境保护和易于清洁。

这种纳米涂层形成一个光滑、疏水的表面,可以排斥水、污垢和污染物,同时还提供抗紫外线和强化学品的能力。

PVD表面陶瓷涂层的主要优点

在PVD上应用陶瓷涂层并非为了使其更坚硬;而是为了使其得到更好的保护,并更易于使用,尤其是在汽车车轮或浴室固定装置等物品上。

增加卓越的疏水性

PVD饰面本身不具有疏水性。陶瓷涂层能产生强烈的水珠和水膜,有助于表面在雨中或冲洗时“自清洁”。

形成牺牲性屏障

陶瓷涂层充当第一道防线。轻微划痕、酸性鸟粪或强力化学清洁剂会损坏可更换的陶瓷涂层,然后才会腐蚀或损害下面的永久性PVD饰面。

增强耐化学性

车轮等物品经常暴露在腐蚀性刹车粉尘、路盐和强力车轮清洁剂中。陶瓷涂层提供了强大的屏障,可抵抗这些化学物质,防止PVD饰面染色和腐蚀。

简化维护

陶瓷涂层光滑、不粘的特性意味着刹车粉尘、污垢和水中的矿物质沉积物很难附着在表面上。清洁通常只需轻轻冲洗即可。

了解权衡

虽然有益,但添加陶瓷涂层并非万能药。客观性要求承认其权衡。

PVD本身已经很耐用

不要将陶瓷涂层的优点误认为是PVD的弱点。PVD本身就是一种极其坚韧耐用的饰面。陶瓷层是维护和化学保护的增强,而不是对抗物理磨损的必要条件。

表面准备至关重要

如果PVD表面没有完全清洁,陶瓷涂层就会失效。任何制造或处理过程中残留的油、蜡或残留物都会阻止正确的化学键合。在涂覆之前,必须立即使用面板预处理喷雾或异丙醇(IPA)对表面进行去污。

成本与附加效益

您必须权衡优质陶瓷涂层的成本和应用时间与所带来的好处。对于展示车的车轮或高端厨房设备,这项投资很容易证明是合理的。对于不太关键的物品,PVD固有的耐用性可能就足够了。

如何将其应用于您的目标

您的决定应基于您对PVD涂层物品的特定目标。

- 如果您的主要关注点是最大程度的划痕和磨损抵抗:PVD涂层本身已经提供了这一核心优势。陶瓷涂层是一个有益但次要的补充。

- 如果您的主要关注点是易于清洁和长期外观:应用陶瓷涂层是一个绝佳的决定。它将大大减少保持PVD饰面焕然一新所需的时间和精力。

- 如果物品处于恶劣环境中(如汽车车轮):强烈推荐使用陶瓷涂层。它提供了对抗刹车粉尘和道路化学品的关键保护,这些化学品最终可能会损坏即使是坚韧的PVD饰面。

通过将PVD的物理硬度与陶瓷涂层的化学保护相结合,您正在创造一种真正兼具两方面优点的饰面。

总结表:

| 涂层类型 | 主要功能 | 主要优点 |

|---|---|---|

| PVD涂层 | 硬度和耐磨性 | 极强的抗刮擦和磨损耐用性 |

| 陶瓷涂层 | 化学和环境防护 | 疏水性、抗紫外线和易清洁 |

准备好用专业级陶瓷涂层保护您的PVD涂层物品了吗?KINTEK专注于为实验室设备和精密部件提供先进的涂层解决方案。我们的专业知识确保您的表面获得最高水平的保护和性能。立即联系我们,了解我们如何增强您实验室设备的耐用性和使用寿命!

图解指南

相关产品

- 倾斜旋转等离子体增强化学气相沉积PECVD设备管式炉

- 实验室塑料PVC压延拉伸薄膜流延机用于薄膜测试

- 触摸屏自动真空热压机

- 实验室吹膜挤出三层共挤吹膜机

- 植物用实验室灭菌器 实验室高压灭菌器 草药粉灭菌机