薄膜沉积部件

实验室用陶瓷蒸发舟 氧化铝坩埚

货号 : KME09

价格根据 规格和定制情况变动

- 材料

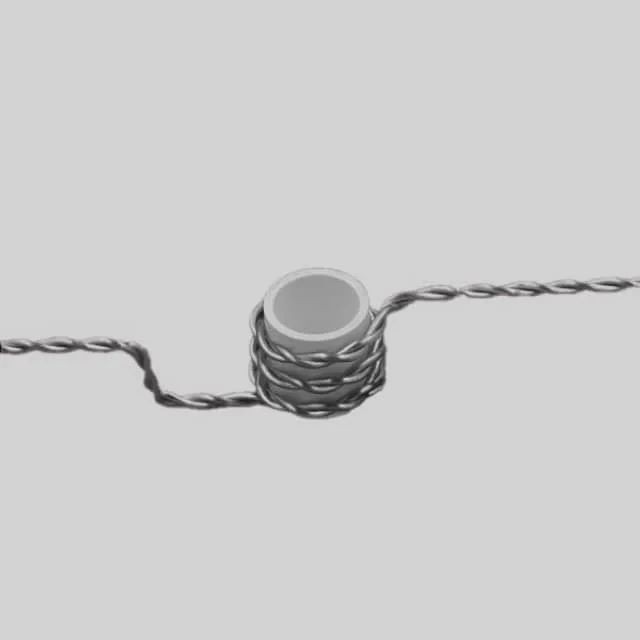

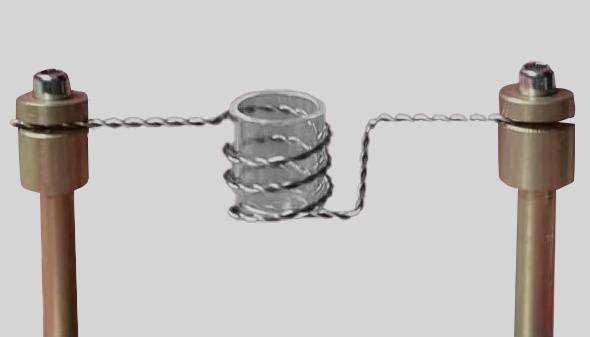

- 陶瓷坩埚/钨丝

- 陶瓷坩埚尺寸

- 0.25毫升/0.5毫升/1.0毫升/2.0毫升/3.0毫升

- 钨丝尺寸

- 3*0.8丝/3*1.0毫米丝/3*0.8丝

运输:

联系我们 获取运输详情 享受 准时发货保证.

为什么选择我们

简易的订购流程、优质的产品和专业的支持,助力您的业务成功。

应用

组合舟组件用于物理气相沉积(PVD)过程,特别是热蒸发。它们由陶瓷舟和钨丝组成。陶瓷蒸发舟由氧化铝或石墨等材料制成,用于盛放待蒸发的材料。当舟被加热时,材料从固态变为气态,从而实现可控蒸发。舟的形状有助于将蒸汽导向基板,实现高效沉积。钨丝用作加热线圈。它连接到电源,当电流通过时,钨丝因其电阻而发热。钨丝具有高熔点和良好的导热性,使其适合此任务。通过提供热量,钨丝使陶瓷舟内的材料蒸发,从而实现可控蒸发。

详情与零件

技术规格

| 材料 | 陶瓷坩埚 / 钨丝 |

| 陶瓷坩埚尺寸 | 0.25ml / 0.5ml / 1.0ml / 2.0ml / 3.0ml |

| 钨丝尺寸 | 3*0.8丝 / 3*1.0丝 / 3*0.8丝 |

我们展示的坩埚有不同尺寸可供选择,也可根据要求定制尺寸。

优点

- 精确的薄膜沉积控制

- 多样的材料沉积能力

- 耐高温

- 高效的热传递

- 可重复和可再现的结果

- 薄膜沉积的经济高效解决方案

行业领军企业信赖之选

FAQ

什么是热蒸发源?

氧化铝坩埚的常见应用有哪些?

使用陶瓷坩埚有哪些优势?

热蒸发源的主要类型有哪些?

使用氧化铝坩埚有哪些优势?

陶瓷坩埚有哪些常见用途?

热蒸发源是如何工作的?

蒸发坩埚常用的材料有哪些?

如何处理和维护氧化铝坩埚?

如何为我的应用选择合适的陶瓷坩埚?

使用热蒸发源有哪些优势?

使用蒸发坩埚有哪些优势?

如何处理和维护陶瓷坩埚?

热蒸发源有哪些应用?

应如何处理和维护蒸发坩埚?

4.8 / 5

These ceramic boats are a game-changer for my lab. The quality is top-notch and they've held up well.

4.9 / 5

KINTEK's evaporation boats provide precise film deposition control. I highly recommend them for thin film deposition.

4.7 / 5

The versatility of these boats is impressive. They handle various materials with ease, making them a valuable asset in my lab.

4.8 / 5

I'm consistently impressed with the high temperature resistance of these boats. They've become an essential part of my research.

4.9 / 5

The efficient heat transfer of these boats has significantly improved the productivity of my lab. Highly recommended!

4.7 / 5

The repeatable and reproducible results I get with these boats are invaluable. They've made my research much more reliable.

4.8 / 5

The cost-effectiveness of these boats makes them a great value for money. I can achieve high-quality thin film deposition without breaking the bank.

4.9 / 5

The custom size options are a lifesaver. I was able to get boats that perfectly fit my specific needs. Thanks, KINTEK!

4.7 / 5

These boats have become an indispensable tool in my lab. Their durability and performance are unmatched.

4.8 / 5

The technological advancement of these boats has revolutionized my research. I can now achieve results that were previously impossible.

4.9 / 5

The speed of delivery was impressive. I received my order within days of placing it. Thank you for the prompt service!

4.7 / 5

The value for money is exceptional. These boats are worth every penny and have saved me a significant amount in the long run.

4.8 / 5

The quality of these boats is outstanding. They are made from high-quality materials and are built to last.

4.9 / 5

The durability of these boats is amazing. I've been using them for months and they still perform like new.

4.7 / 5

The technological advancement of these boats is impressive. They incorporate the latest technology to deliver exceptional results.

4.8 / 5

These boats are a game-changer for my lab. They've helped me achieve results that I never thought possible.

4.9 / 5

I highly recommend these boats to anyone looking for high-quality and reliable evaporation solutions.

4.7 / 5

These boats have exceeded my expectations. They are a valuable addition to my lab equipment.

4.8 / 5

I'm glad I made the switch to these boats. They've made my research more efficient and productive.

4.9 / 5

These boats are a must-have for any lab conducting thin film deposition. They are reliable, accurate, and easy to use.

获取报价

我们的专业团队将在一个工作日内回复您。请随时与我们联系!

相关产品

弧形氧化铝陶瓷坩埚 高温耐受工程先进陶瓷

在科学探索和工业生产的征程中,每一个细节都至关重要。我们的弧形氧化铝陶瓷坩埚,凭借其出色的耐高温性和稳定的化学性质,已成为实验室和工业领域的得力助手。它们采用高纯度氧化铝材料制成,并经过精密工艺制造,确保在极端环境下也能有卓越的表现。

相关文章

化学气相沉积与物理气相沉积的比较

化学气相沉积 (CVD) VS 物理气相沉积 (PVD)

薄膜沉积中蒸发和溅射技术的比较研究

最常用的两种薄膜沉积技术是蒸发和溅射。

了解真空镀膜中的蒸发舟

深入了解真空镀膜工艺中的蒸发舟、材料、布置、温度控制和腐蚀问题。

用于电池涂层的 PECVD 石墨舟

探索在 PECVD 中使用石墨舟实现高效电池涂层。

电子束蒸发涂层技术和材料选择

深入探讨电子束蒸发涂层技术的原理和应用,包括材料选择和各种应用领域。

电子束蒸发:先进的薄膜制造

探讨电子束蒸发在薄膜生产中的技术和应用。

真空镀膜中的电子束蒸发技术

深入了解电子束蒸发及其在真空镀膜工艺中的类型、优点和缺点。

电子束蒸发涂层:原理、特点和应用

深入分析电子束蒸发涂层技术及其优缺点和在薄膜制造中的应用。

电子束蒸发涂层:优缺点与应用

深入了解电子束蒸发涂层的优缺点及其在工业中的各种应用。

真空蒸发系统综合概述

深入了解真空蒸发系统及其原理、组件和应用。

蒸发涂层的蒸发源类型

探索薄膜沉积中使用的不同蒸发源,包括灯丝、坩埚和蒸发舟。

了解蒸发电镀、溅射电镀和离子镀

详细比较蒸发电镀、溅射电镀和离子电镀技术及其原理、类型和特点。