“坑式炉”(pit furnace)一词指的是炉子的物理方向,而不是其产生热量的方法。它是一种安装在低于地面水平的坑中的垂直炉,这种设计专门用于对需要垂直保持以防止在高温下发生下垂或变形的长或重型部件进行热处理。实际的加热可以通过多种方法实现,包括电阻电加热、燃气燃烧或感应加热。

坑式炉从根本上说是一种结构设计选择,而不是一种加热技术。其明确的特点是垂直的、地下室的腔室,非常适合加工长轴和管等零件,而不会产生重力变形。在腔室内部产生热量所使用的方法是一个单独的关键决策。

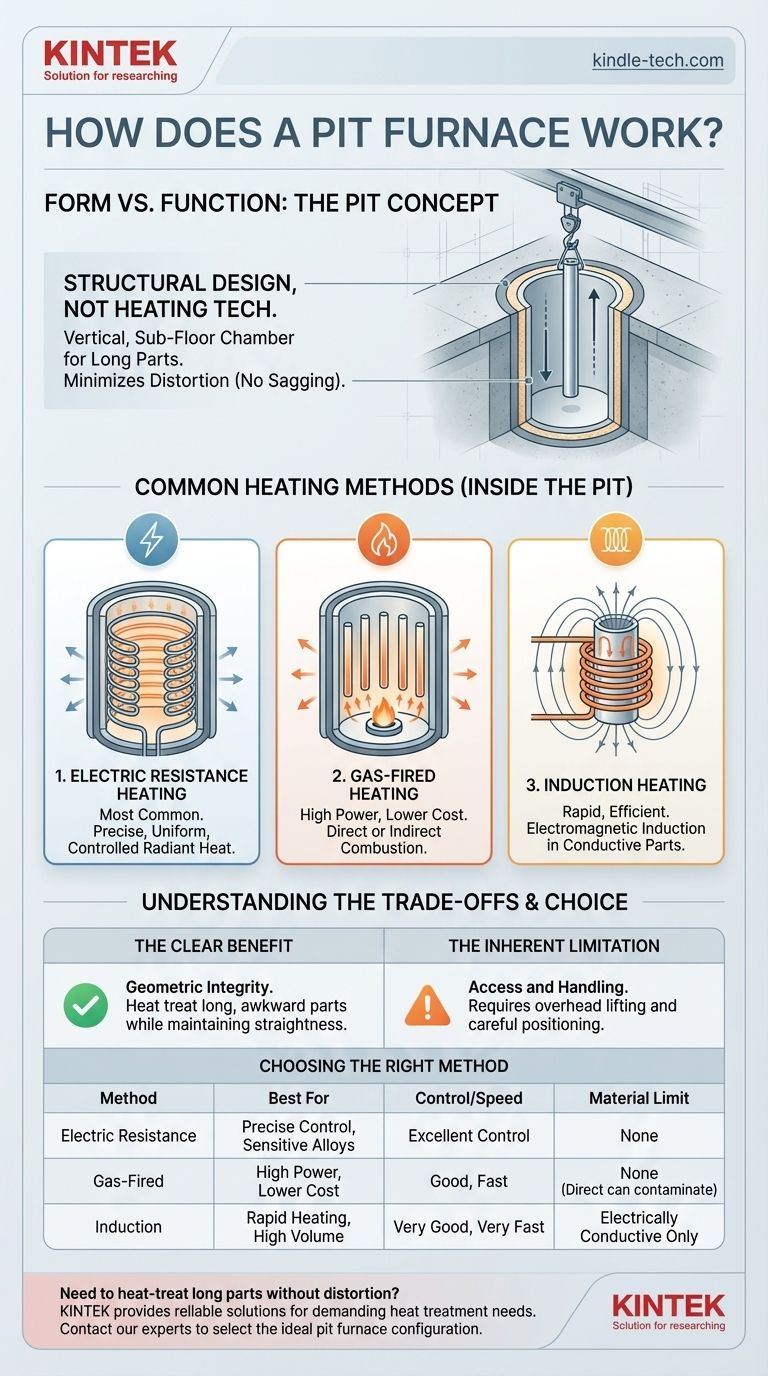

剖析坑式炉:形式与功能

一个常见的混淆点是将炉子的形状误认为是其能源。实际上,“坑式”配置是解决特定机械问题的方案,而加热元件是解决热问题的方案。

明确的特点:垂直的、地下的腔室

该炉子由一个圆柱形或矩形的绝缘腔室组成,该腔室沉入工厂地板的坑中。

零件通常通过起重机从顶部垂直装载和卸载。这种设计使炉体的主体远离工作区域,节省了宝贵的地面空间。

核心目的:最小化变形

使用坑式炉的主要原因是为了控制重力对长而细的零件在热处理过程中产生的影响。

当一根长轴、管或螺钉在水平炉中加热到高温时,其自身的重量可能导致其弯曲或下垂。通过垂直悬挂零件,可以消除这些导致变形的应力,确保尺寸稳定性。

坑式炉中的常见加热方法

虽然坑定义了形状,但内部的技术产生了热量。加热方法的选择取决于材料、所需温度精度和运营成本。

电阻电加热

这是坑式炉中最常用的方法,用于退火、回火和淬火等热处理应用。

就像传统的烤箱一样,电阻电加热元件排列在炉子的内壁上。电流通过这些高电阻元件,产生均匀、可精确控制的辐射热。

燃气加热

对于温度精确控制不如原始加热功率和较低运营成本重要的应用,会使用燃气系统。

燃烧器燃烧天然气或丙烷等燃料。这可以是“直接燃烧”,即燃烧产物进入腔室;也可以是“间接燃烧”,即火焰加热辐射管,辐射管反过来加热腔室,使工件免受火焰的直接影响。

感应加热

如感应炉原理所述,该方法使用电磁场直接在工件内部产生热量。

在坑式炉的背景下,一个铜线圈会被降低到腔室内部,环绕着导电金属零件。线圈中的交流电会在零件内部感应出强大的涡流,使其从内部到外部快速有效地加热。这种方法非常快,但仅限于导电材料。

理解权衡

选择坑式炉及其加热系统需要在不同的优势和局限性之间取得平衡。

明确的优势:几何完整性

最大的优势是能够在保持长、笨重或细长零件的直线度和尺寸精度的同时对其进行热处理。对于飞机起落架、大型工业轴或枪管等部件来说,这是不容妥协的。

固有的局限性:可及性和处理

与水平炉或箱式炉相比,地下设计可能会使维护的访问变得复杂。装载和卸载还需要可靠的起重设备和工件的精确就位。

加热方法决定性能

在电加热、燃气加热或感应加热之间进行选择是一种关键的权衡:

- 电阻电加热提供最佳的温度均匀性和控制,对敏感合金至关重要,但运营成本可能较高。

- 燃气加热系统通常运行成本更低,并提供巨大的加热能力,但在温度控制精度上稍逊一筹,且直接燃烧设计可能存在大气污染的风险。

- 感应加热是最快、最高效的加热方法,但设备专业化,并且仅适用于导电材料。

为您的目标做出正确的选择

理想的炉子是正确的物理形式与适合该工作的正确加热技术的结合。

- 如果您的主要重点是处理有变形风险的长、细零件: 无论采用何种加热方法,坑式炉都是正确的物理配置。

- 如果您的主要重点是对敏感合金实现精确和均匀的温度: 电加热坑式炉是其控制和清洁度的更优选择。

- 如果您的主要重点是快速高效地加热大批量导电零件: 安装在坑式炉中的感应加热系统提供了无与伦比的速度和能源效率。

最终,选择正确的工业炉意味着将设备的结构和功能与您的特定材料和生产目标相匹配。

摘要表:

| 特性 | 电阻电加热 | 燃气加热 | 感应加热 |

|---|---|---|---|

| 最适合 | 精确的温度控制,敏感合金 | 高功率,较低的运营成本 | 快速加热,导电金属 |

| 温度控制 | 优秀 | 良好 | 非常好 |

| 加热速度 | 中等 | 快 | 非常快 |

| 材料限制 | 无 | 无(直接燃烧可能造成污染) | 仅限导电材料 |

需要对长、重或细零件进行无变形热处理吗?

KINTEK 专注于实验室设备和消耗品,为要求苛刻的实验室和工业热处理需求提供可靠的解决方案。我们的专业知识可以帮助您选择理想的坑式炉配置——无论是电加热、燃气加热还是感应加热——以确保您的部件保持几何完整性并满足您精确的材料规格。

立即联系我们的专家,讨论您的应用并发现适合您目标的正确炉子!

图解指南