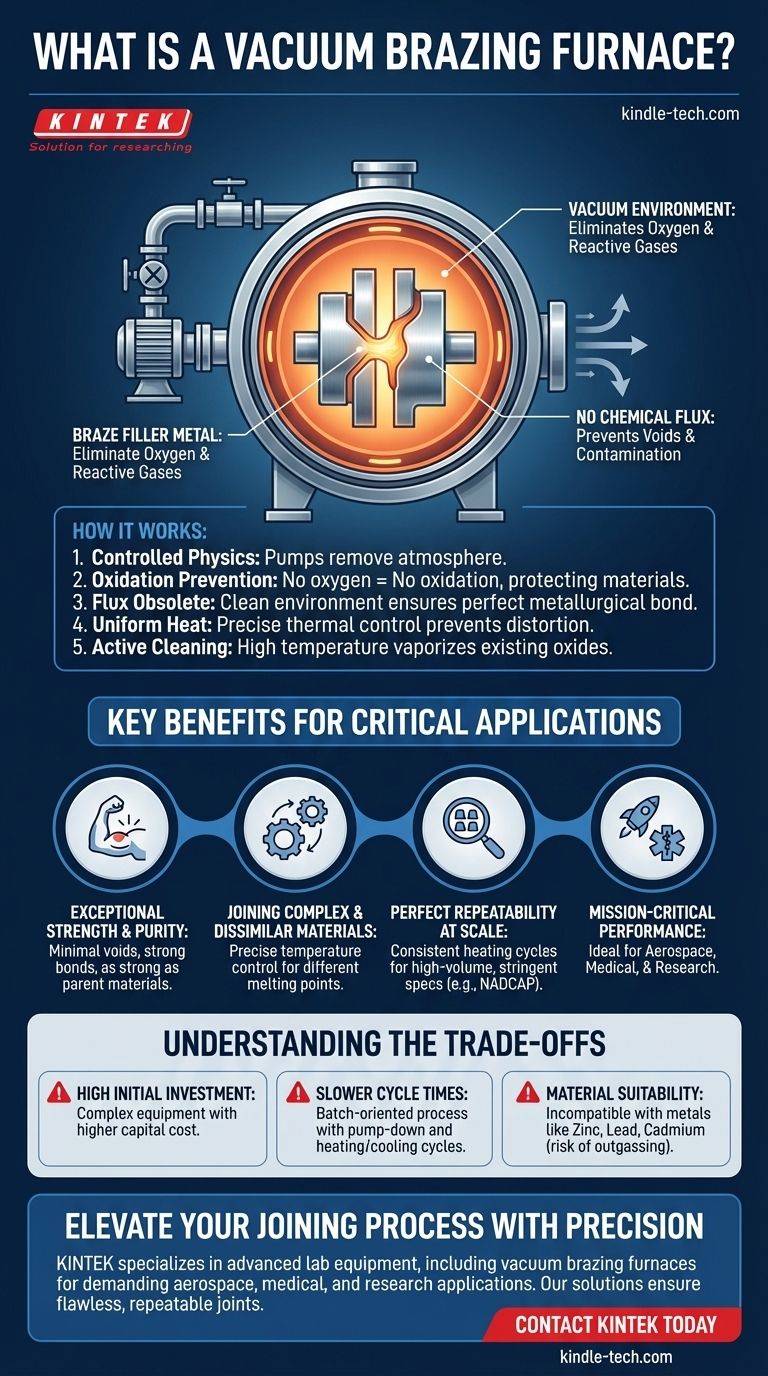

本质上,真空钎焊炉是一个高度受控的腔室,它在近乎完全真空的环境中,使用填充金属将材料连接在一起。通过去除氧气等活性气体,炉子创造了一个理想的环境,防止在加热过程中发生氧化和污染。这使得无需化学助焊剂即可获得异常坚固、清洁和精确的接头。

真空炉的关键优势不仅仅是防止污染;它还在于创造一个活跃的环境以实现完美。真空主动保护组件,可以去除现有的表面氧化物,并提供无与伦比的温度控制,使其成为连接高性能、任务关键型零件的明确选择。

真空炉如何实现卓越的接头

要理解真空炉的价值,您必须超越简单的零件连接,而专注于它所创造的环境的受控物理特性。

真空环境的作用

由泵、阀门和仪表组成的真空系统,负责从密封的炉腔中抽除大气。

这实现了一个关键目标:消除氧气和其他活性气体。没有氧气,即使在钎焊所需的高温下,氧化也根本不会发生。

这保护了基材和填充金属的完整性,确保最终接头纯净且不含降低性能的氧化物。

无需助焊剂即可消除污染

传统的钎焊方法依赖化学助焊剂来清洁表面并防止氧化。

然而,助焊剂可能会滞留在接头中,形成空隙和潜在的失效点。它还会留下腐蚀性残留物,需要进行强力的焊后清洁。

真空炉使助焊剂完全过时。清洁的环境确保了完美的冶金结合,而不会引入任何外部污染物。

无与伦比的温度控制

真空炉提供极其均匀的热量分布。这确保了复杂的组件,无论其几何形状如何,都能均匀受热。

这种精确的控制可以防止热变形,这是其他连接工艺中常见的局部加热导致零件翘曲的问题。

炉子可以以完美的精度执行预编程的加热和冷却循环,确保每个零件都在完全相同的条件下进行处理。

主动清洁零件表面

与直觉相反,真空炉可以在高于氧化物形成点的温度下运行。

在无氧环境中,这种高温会导致组件上现有的轻微氧化层分解并汽化。炉子不仅可以防止新的氧化物形成;它还可以去除旧的氧化物,进一步确保钎焊合金的原始表面。

关键应用的主要优势

真空炉的受控环境直接转化为切实的优势,特别是对于不允许失败的行业。

卓越的接头强度和纯度

通过消除氧化物和助焊剂滞留,该工艺生产的接头具有最小的空隙和卓越的机械性能。最终的结合强度通常与母材本身一样强。

连接复杂和异种材料

精确的温度控制允许成功钎焊具有不同熔点或热膨胀系数的材料。它是具有复杂几何形状的精密组件的理想解决方案。

大规模完美重复性

复杂的控制系统,有时与条形码连接,允许炉子为每个批次运行相同的加热循环。这对于大批量制造非常宝贵,其中每个零件都必须符合严格的规范,例如航空航天行业NADCAP所要求的规范。

了解权衡

虽然功能强大,但真空炉钎焊并非适用于所有应用。客观性要求承认其局限性。

高初始投资

真空炉是复杂的设备。初始资本成本显著高于大多数其他连接设备。

较慢的循环时间

该过程本质上是批处理的。需要时间来加载零件、将腔室抽至深真空、运行加热和冷却循环以及排空炉子。这使得它不太适合高速、连续的生产线。

材料适用性

某些材料不兼容真空环境。具有高蒸汽压的金属,如锌、铅或镉,在钎焊温度下会逸出气体,污染炉子并损害接头。

为您的目标做出正确选择

选择真空炉钎焊是基于最终组件所需的精度、纯度和性能水平的决定。

- 如果您的主要关注点是任务关键型性能:这是航空航天、医疗和研究应用的标准,在这些应用中,接头失效将导致灾难性后果。

- 如果您的主要关注点是连接复杂或异种材料:炉子的精确热管理对于在复杂组件中创建无应力接头至关重要。

- 如果您的主要关注点是大批量、高精度制造:该工艺无与伦比的重复性确保大批量生产中的每个零件都符合完全相同的质量标准。

- 如果您的主要关注点是保持零件的绝对完整性:对于不能容忍任何热变形或助焊剂污染的组件,真空钎焊是理想的方法。

最终,真空钎焊炉是对确定性的投资,在精度至关重要的地方提供完美且可重复的接头。

总结表:

| 特点 | 优点 |

|---|---|

| 无氧真空环境 | 防止氧化和污染,无需化学助焊剂 |

| 精确的温度控制 | 确保均匀加热,防止变形,并处理复杂的几何形状 |

| 主动表面清洁 | 在高温下去除现有氧化物,获得原始的粘合表面 |

| 卓越的接头完整性 | 生产空隙极少、强度高、通常与基材一样坚固的接头 |

| 完美的可重复性 | 非常适合大批量、高精度制造,结果一致 |

准备好通过精度和可靠性提升您的连接工艺了吗?

在KINTEK,我们专注于先进的实验室设备,包括专为航空航天、医疗和研究领域的严苛应用而设计的真空钎焊炉。我们的解决方案确保任务关键型组件的完美、可重复接头。

立即联系我们,讨论我们的专业知识如何帮助您取得卓越成果 — 通过我们的联系表格与我们取得联系!

图解指南