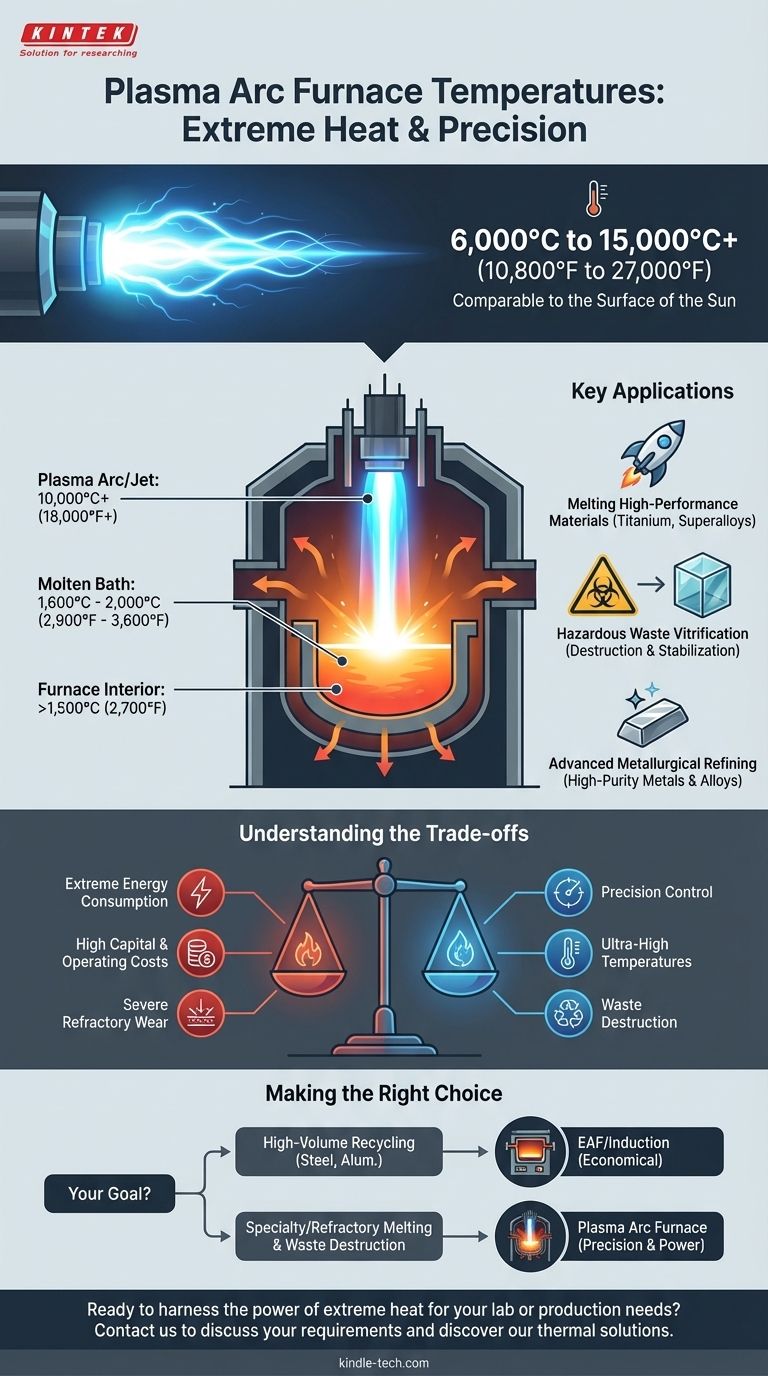

从本质上讲,等离子电弧炉的工作温度超越了传统加热方法的极限,其等离子射流本身的温度可达到 6,000°C 至 15,000°C 以上(10,800°F 至 27,000°F)。这与太阳表面温度相当。然而,这种极端热量高度集中在电弧区域,而熔融材料和炉膛内部的温度则不同,要低一些。

等离子电弧炉的决定性特征不仅在于其极端的高温,还在于它能够精确、可控地输送热量。这使其从简单的熔化设备转变为先进材料加工和废物销毁的精密工具。

等离子电弧如何实现极端温度

要理解该炉,首先必须了解等离子体。等离子体是物质的第四态,当气体被激发到电子从原子中剥离的点时形成,形成电离的、导电的气体。

等离子体产生的原理

等离子炬在气体(如氩气、氮气甚至空气)流中产生高压电弧,类似于闪电。这种强烈的电能使气体过热,使其电离并产生集中的等离子射流。该射流的稳定性和温度由电源和气体流量精确控制。

转移电弧与非转移电弧

主要有两种配置。转移电弧形成于炬头电极与被加热的导电材料(“炉料”)之间。这种方法在将能量直接传递到目标物方面效率极高,非常适合熔化金属。

非转移电弧完全包含在炬头内部。然后,等离子体作为高速的过热气体射流喷出。这通常用于热喷涂或销毁不导电的废物等应用。

炉内热量的结构

至关重要的是要理解,等离子炉并非只有一个温度。它有不同的热区。

- 等离子电弧/射流:电弧的核心是最热点,达到 10,000°C 以上。这是电离物理发生的地方。

- 熔融池:被熔化的材料,如钢或钛,通常保持在维持其液态所需的温度,通常在 1,600°C 至 2,000°C 之间。等离子电弧充当维持该温度的热源。

- 炉膛内部(自由空间):熔融池上方的空间比电弧区域凉爽得多,但仍然非常热,通常保持在 1,500°C 以上的温度。

为什么这种温度水平很重要:关键应用

等离子电弧加热的独特能力使得使用传统熔炉(如电弧炉或感应炉)难以或不可能实现的过程得以实现。

熔化高性能材料

主要优势在于熔化具有极高熔点的金属和陶瓷。这包括 钛、镍基高温合金和难熔金属,如钨和钼,它们对于航空航天、国防和医疗应用至关重要。

危险废物玻璃化

等离子加热是销毁危险材料的明确解决方案。极端的高温将复杂的有机化合物、石棉和医疗废物分解成其元素成分。然后将这些元素冷却并熔合成一种稳定的、不渗滤的玻璃状固体,称为炉渣。

先进冶金精炼

极端高温与受控气氛的结合,实现了卓越的冶金精炼。它能够有效去除杂质,并生产出成分精确控制的高纯度金属和合金。

了解权衡

等离子技术的卓越能力伴随着重大的操作考量。它并非适用于所有任务的正确工具。

巨大的能源消耗

产生和维持稳定的等离子电弧需要巨大的电能。这使得该过程比用于标准钢材回收的传统电弧炉(EAF)在每吨上的能耗和成本要高得多。

高昂的资本和运营成本

等离子炬、其专用电源和气体输送系统复杂且昂贵。此外,氩气等等离子气体的成本可能是一项主要的运营支出,尽管有些系统设计为使用空气运行。

严重的耐火材料损耗

等离子电弧的强烈、集中的热量对炉衬的耐火材料具有极强的破坏性。这种“耐火材料损耗”是主要的运营挑战,与其他类型的炉子相比,会导致更高的维护成本和停机时间。

为您的目标做出正确的选择

选择正确的加热技术完全取决于您的特定材料和加工目标。

- 如果您的主要重点是钢或铝等标准金属的大批量回收: 传统电弧炉(EAF)或感应炉几乎总是更经济、更高效的选择。

- 如果您的主要重点是熔化特种合金、钛或难熔金属: 等离子电弧炉提供了其他技术无法比拟的必要温度、控制和洁净环境。

- 如果您的主要重点是彻底销毁危险废物或制造超纯材料: 等离子电弧炉是明确的工具,它在热分解和精炼方面提供了无与伦比的水平。

最终,等离子电弧炉最好被视为一种精密仪器,用于在最基本的层面上操纵物质,而不是一种蛮力加热器。

摘要表:

| 特性 | 温度范围 | 关键应用 |

|---|---|---|

| 等离子电弧/射流 | 10,000°C+ (18,000°F+) | 电离,极端加热 |

| 熔融材料 | 1,600°C - 2,000°C (2,900°F - 3,600°F) | 熔化金属、合金 |

| 炉膛内部 | >1,500°C (2,700°F) | 受控气氛加工 |

准备好利用极端热量为您的实验室或生产需求服务了吗?

在 KINTEK,我们专注于先进的热解决方案,包括专为精确熔化高性能合金、难熔金属和危险废物玻璃化而设计的等离子电弧炉。我们的专业知识确保您获得正确的设备,以实现卓越的材料加工和控制。

立即联系我们,讨论您的具体要求,并了解我们的实验室设备如何提升您的研究或生产能力。立即联系我们的专家!

图解指南